Build date +48

More cab work, last week wasn't good for progress, a few steps forward and a few backward.

I commented earlier about the cab windows and the tops being part of the cab area that curves at cant rail level, looking at photos in detail some engines have flat cab sides fore and aft of the cab windows and some have a slight bow. The cab windows are mounted in a wooden frame that sits inside the sheet work. The kit cab rear wall and front spectacle plate work all have a slight bow, so if you wanted to model an engine with flat sides you'll need to flatted those areas and adjust the side sheet to suit. Some engines have flat sides with a small curve at the top, others curved rear edges but flat where it meets the window frame, it's all down to plate work and fitters at works and depots I suppose.

I'd of been happy just leaving it all as it was with a slight curve front and rear and trying to flatten the area by the cab windows, however, C't'ain cockup and his merry crew had a really wild party around this area so I was left with a bit of a mess, all self inflicted.

The first problem was getting a smooth arc and curve at the cant rail, the open window allows that section of material to bow and the bend becomes un uniform, good skills and craftsmanship can resolve this, both of which deserted me on both sides of the cab. In the end I managed to smooth it all out using a suitable former behind the bend and tapping gently with a wooden file handle to get a constant curve. The second issue came when I annealed the area around the bend, very close to this is the half etched window frame which expanded faster than the surrounding full thickness material and thus bowed out.

I'd spotted the problem soon after finishing the basic cab work but had to wait until the cab windscreen plate work was in place to add strength to the front area ahead of the side windows.

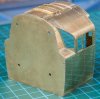

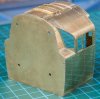

A picture is worth a thousand words so here's 5000 of them. Note, these are really ugly close ups

No matter what I tried the metal frame would not flatten and being part of a detailed area couldn't really be chopped and shut effectively, note also the curving of the sheetwork ahead of the window frame at the cant rail level, resulting in the glazing not sitting flat within the frame.

Biting the bullet the only real solution was to remove the whole window frame and start again, both the 9'-0" and 8'-6" cabs are identical in this area (which they shouldn't be....more later) so it was simply a case of cutting out the frames from the spare 8'-6" cab.

Note again curved sheet work at cant rail level and the more gentle arc at the rear.

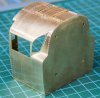

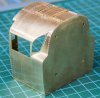

New cab window.

The cab side has a half etched rebate around the windows to simulate the installation, by careful cutting and measuring I was able to file right up to the recess but leave it with raised edges both sides.

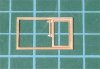

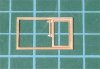

Trial fitting of new flat window frames.

I'm happy with that, one of the other issues with cutting out the old windscreen is that it comes very close to some etched rivet holes on the rear face and a couple of these have been exposed during cutting back, a little dab of solder and some cleaning up should remove them.

On top I did manage most of the additional bits this week, a sliding ventilator, safety straps and other covers, all very neat, all fitted perfectly and very enjoyable detail work. I've still got the lifting lugs to form and fit and there's a couple of white metal vents to add.

Ok cab windows, there appears to be three types of cab window, the two obvious and well documented types and a third sub variant.

The original order of engines with air smoothed cabs, all 8'-6" wide, had large side windows with two windows. When these were modified with V screen cabs the side window arrangement changed to a smaller opening with three windows fitted. However, when the 9'-0" cabs were built they enlarged the window opening, still with three windows in, but the rear edge was moved backward several inches.

8'-6" air smoothed cab with reduced cab window width, note extra width of rear cab sheet work.

Copyright with original owner, crop shown for information purposes.

Note change in cant rail curve at rear end, large radius to the rear and tighter one by the cab window so as to make the side sheet flat for the full height of the cab window.

Now the 9'-0" air smoothed cab, note reduced sheet work for enlarged window.

Copyright with original owner, crop shown for information purposes.

Note the cant rail curve in the side sheet to the rear of the window and flat window frame within.

Interestingly when air smoothed engines were modified to standard form they all received 9'-0" cabs, however they did not receive the 9'-0" cab side window arrangement, they retained their small openings from the original 8'-6" cab design, one presumes to enable the cab window frames recovered from the original engine rather than have to make new ones.

MD

T-7

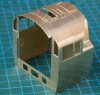

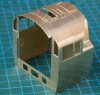

and assembled it all, it was only fair to check the end result and see if it was all worth it.

and assembled it all, it was only fair to check the end result and see if it was all worth it.