Moving glacially onward it's time to tackle the cab and backhead.

This is where I diverted from the instructions and added the mandatory Mickoo dabbling, for no other reason than it made things easier for my style of workflow.

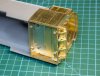

The kit builds up with the backhead floor attached to the chassis and as such has brackets to hold the pipework below the footplate. The cab floor is cleverly split into two, the rear half attached to the cab and body structure, the front under the backhead is attached to the chassis.

When attaching the body simply slip over the back head, lower and fix into place, works well but for clumsy clutz like me is a wide open door for C'tain cock up and his merry crew to walk right on it!

Two reasons, working on the backhead whilst attached the frames makes it a bit of a hand full on the work bench, you can off course choose not attach the floor to the chassis until you have completed all of the backhead work and then affix it followed by the underfloor pipework, however you need to think ahead if you take this path as the instructions have you fit the floor and pipework back earlier in the build. There is nothing wrong with this approach if that suits your workflow and it is a testament to the design of the kit that you can rather easily change your build flow to suit your needs.

The second reason is that at this stage of the build, the body is going on and off for instruction photos, pr- painting and continual other works, which makes all of the fine details on the backhead prone to damage from Herr Ten thumbs here!

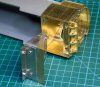

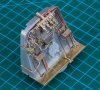

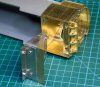

So what's to do, first off I cut off the brackets designed to hold the under floor pipework and will fabricate a suitable replacement and attach it to the frames, second was to fabricate a new backhead floor fixing bracket that will hold it in the cab. A simple angle bracket was fabricated and associated fixings used to join it to the cab front wall.

Now the backhead and floor are affixed to the cab and delicate details are all self contained within the cab and protected from Herr Ten thumbs.

The other advantage is that the backhead sub assembly can be worked on with ease on the workbench, a much smaller assembly and easier to manipulate should result in less damage to the rest of the engine and backhead details.

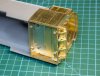

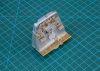

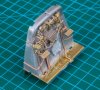

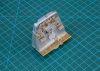

So the whole of this week was spent working out how to build this complex and detailed sub assembly, several parts are only placed into position for the photos, they need to come out either for painting behind, attaching delicate pipework or impact the path of other pipework, there being several layers of pipework to be added.

And the nicely detailed steam manifold, which when fitted is tight up against the roof and a lot of this detail is lost, but I know it's there

For the instruction photos the steam manifold is removed as it covers a lot of the small detail parts underneath, once fitted you can see the limited clearances for further detailing and pipework fitting, so this is a sub assembly in it's own right and goes on last.

The plan for the rest of the weekend and next week to is to complete the pipework, many of the pipes pass through the floor so associated openings and slots will need drilling out so that the pipes can pass through. The cab is a high detail area so the effort is worth it I feel.

Two things I've noticed, the joint lines on the castings are near invisible to the eye yet the digital camera picks them out like stars in the night sky, second, few light Pacific cabs are the same, so research and pick a cab and then follow that, many today have had modifications that were not present back in the day so builder beware.

As far as I can ascertain, original engines retained their UV cab lighting and thus had black gauge faces with luminous markings, rebuilt engines appear to have gone over to standard lamps and as such have white gauge faces, this engine will have the original UV lighting set up. Beware though, post BR I suspect many preserved engines in original form may well have had their lighting converted to standard lamps and some rebuilt engines had UV gauges fitted, I've not managed to find good cab shots of all the preserved examples yet.

MD