Jim smith-wright

Western Thunderer

Hi All

I am currently embarked on building a test build of the forthcoming Brassmasters Coronation or Duchess kit. Way before I got distracted with Brettell Road I always thought that if Brassmasters ever did a Duchess i would have a go at building one as 46235 'City of Birmingham'. Well now they are and so I am!

Of course its a personal opinion thing but I never really liked streamlined steam locos. While the Duchesses were a little more thoughtfully designed than the god awful GWR efforts I always thought they looked a bit like an upturned bath tub and have to admit the A4's did look a fair bit better. However with the streamlining taken off the Duchesses were 'it'. The steam locomotive version of the Concorde moment. To my eyes, at least, the pinnacle of steam loco perfection.

Anyway enough hero worship and on to the model. Starting with...

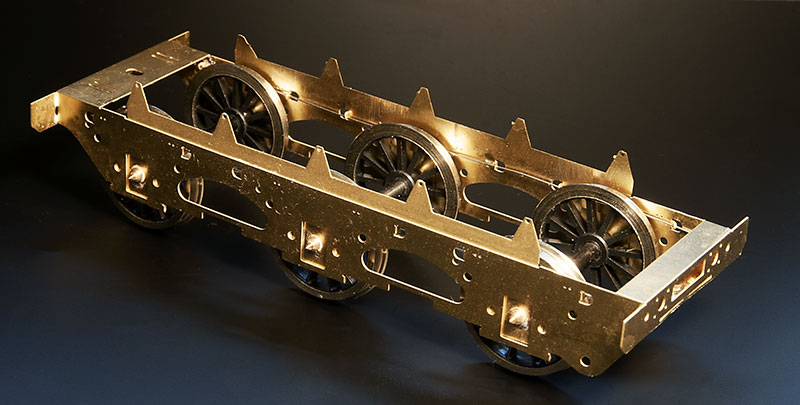

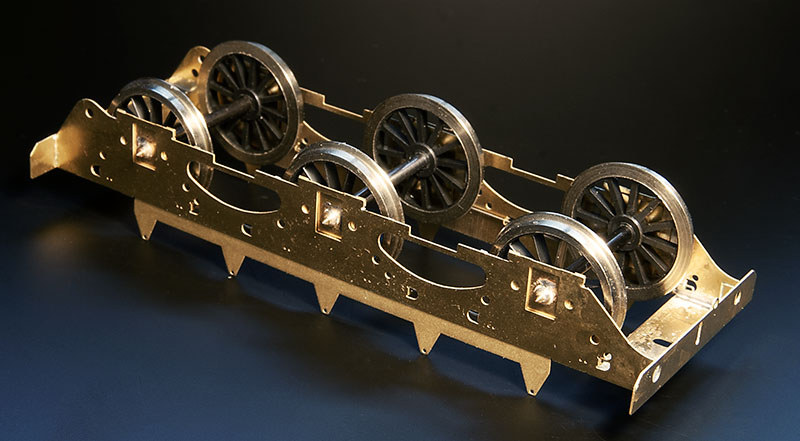

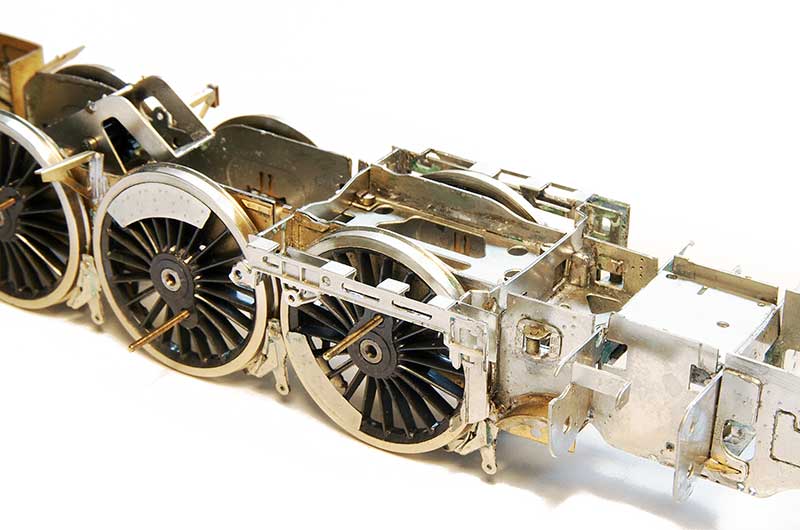

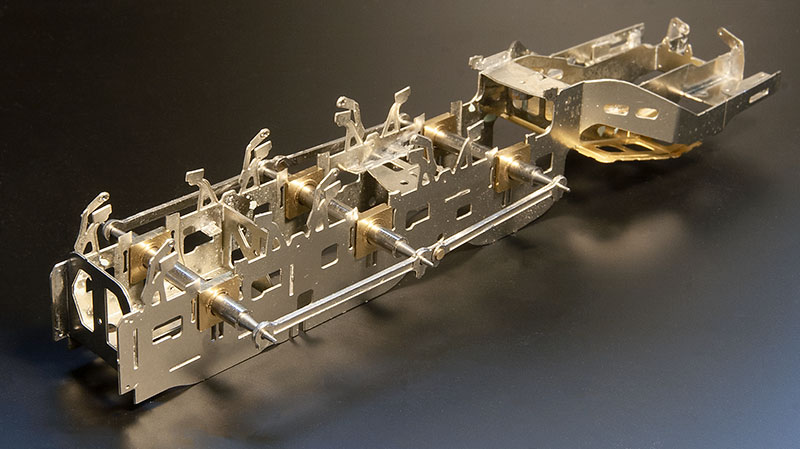

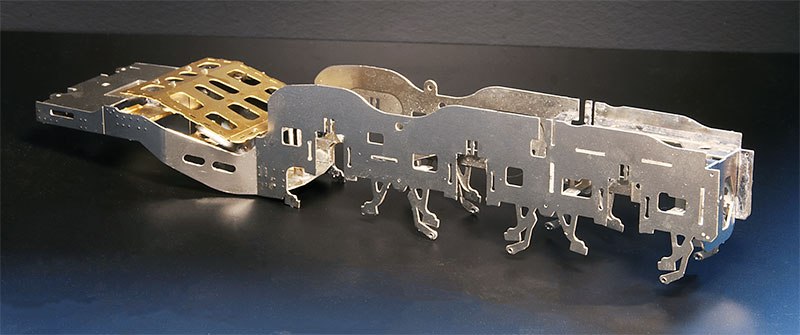

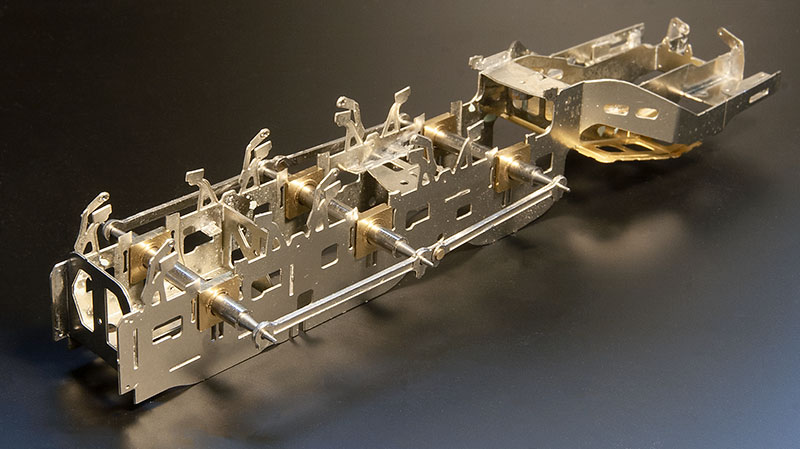

The main sub-frames. The loco frames come in 3 sub sections related to the wheels. A driving wheel section, a pony truck section and a bogie section.

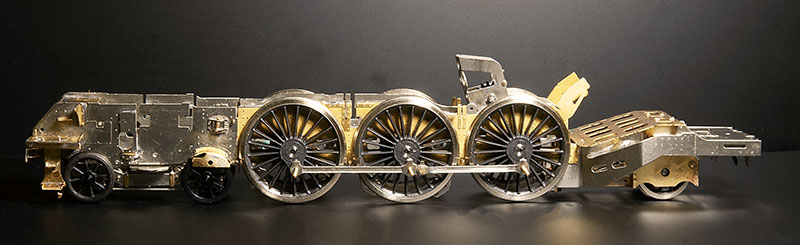

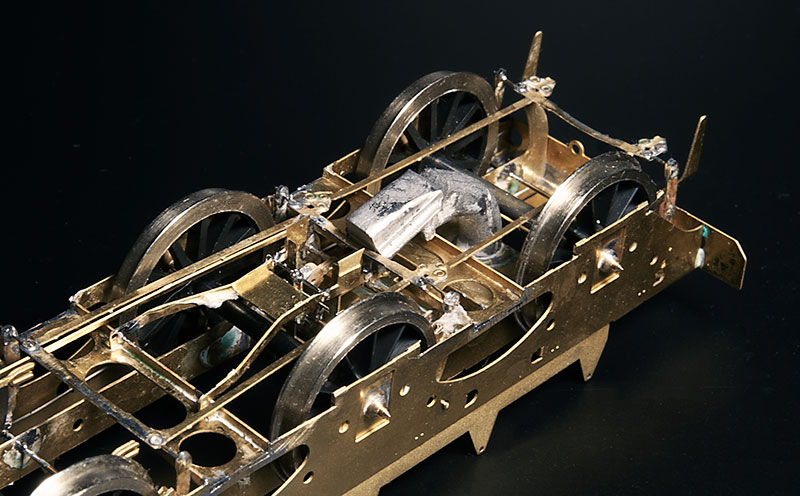

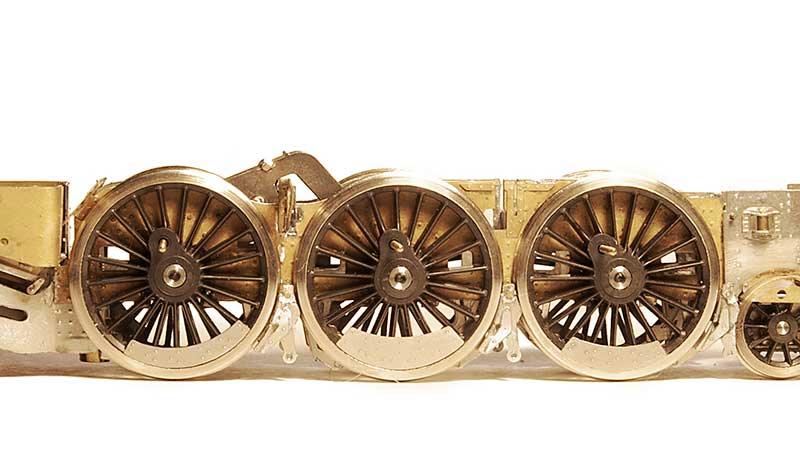

The chassis upside down, test fitting the main coupling rods.

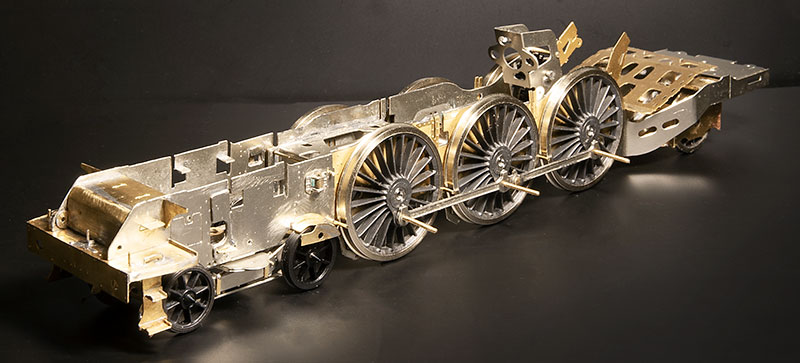

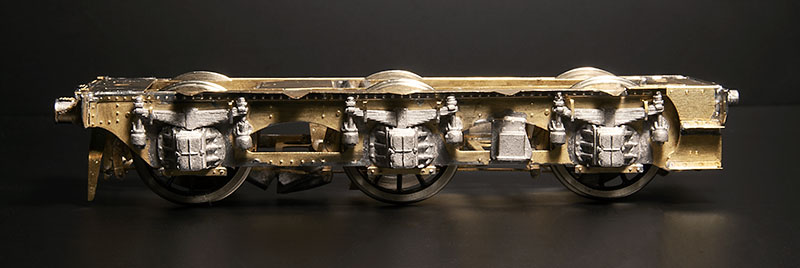

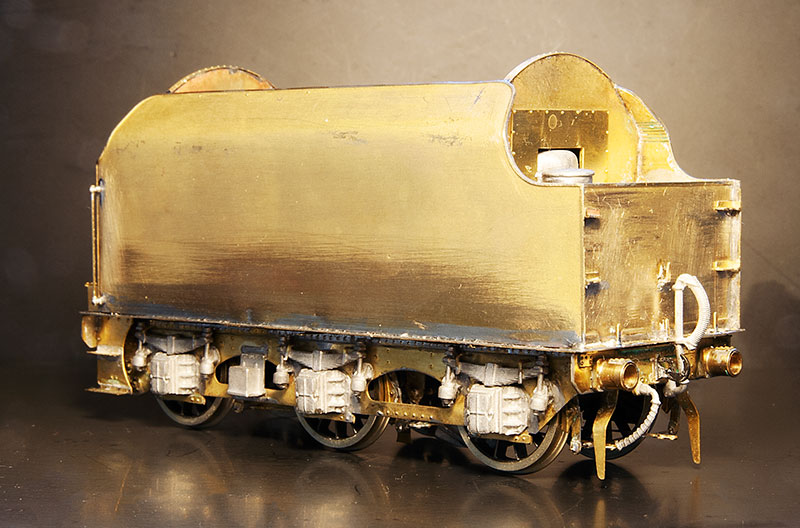

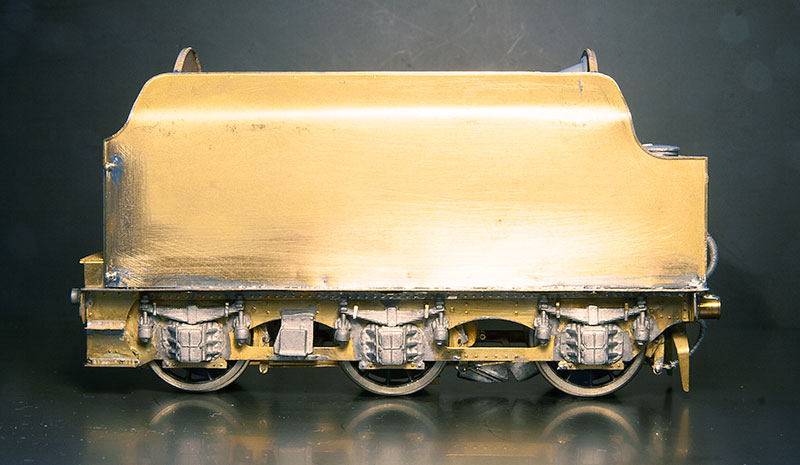

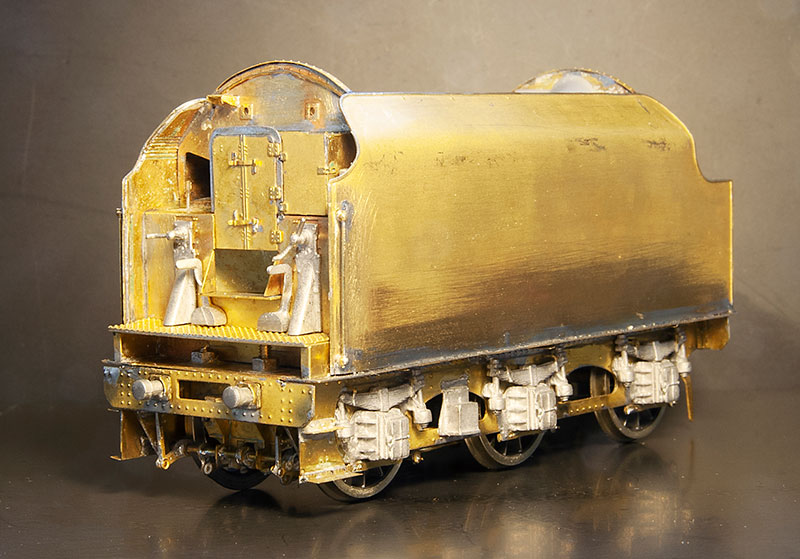

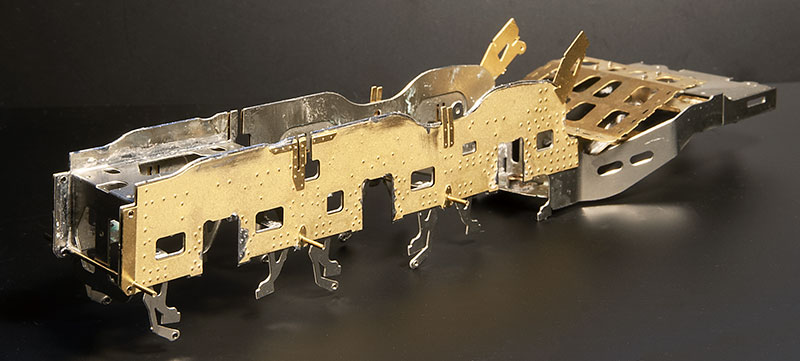

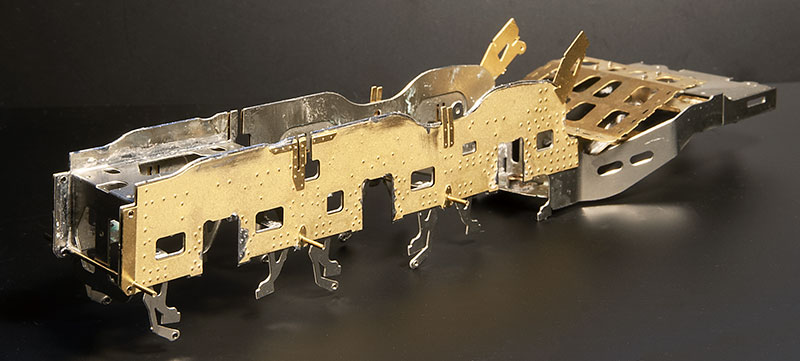

The main frame with the brass overlays fitted.

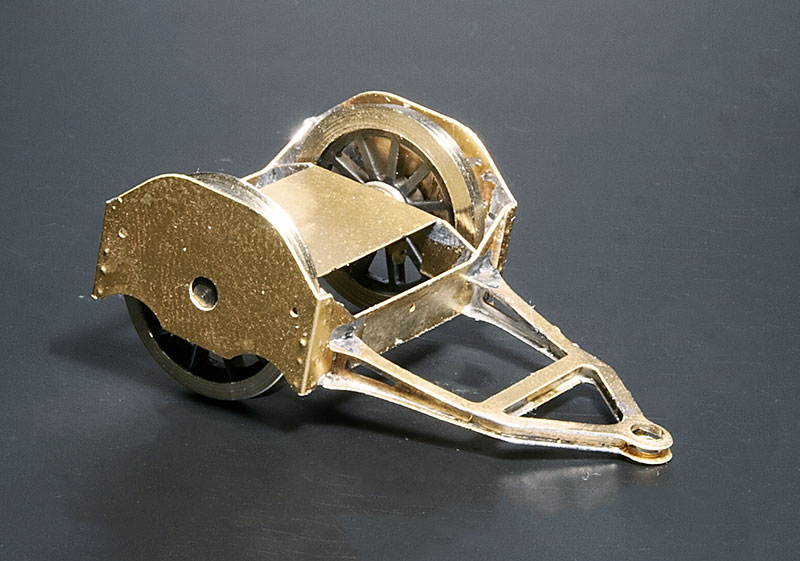

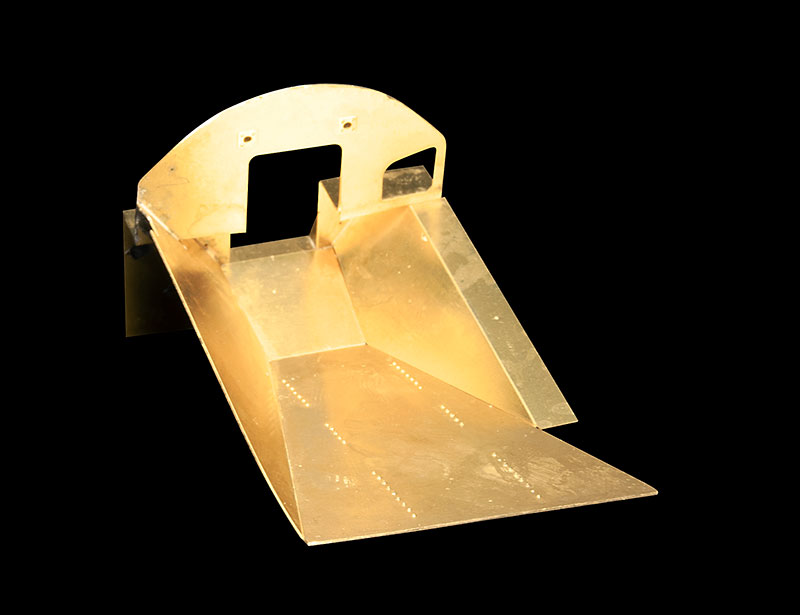

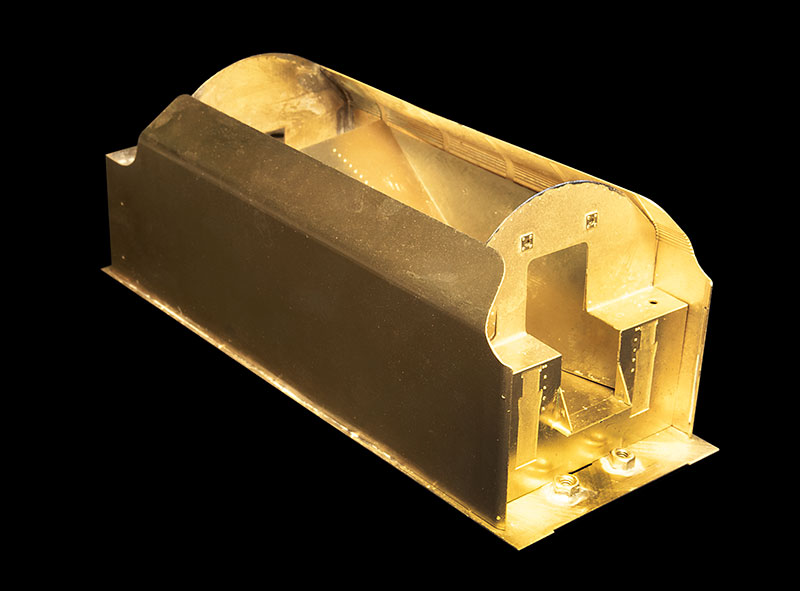

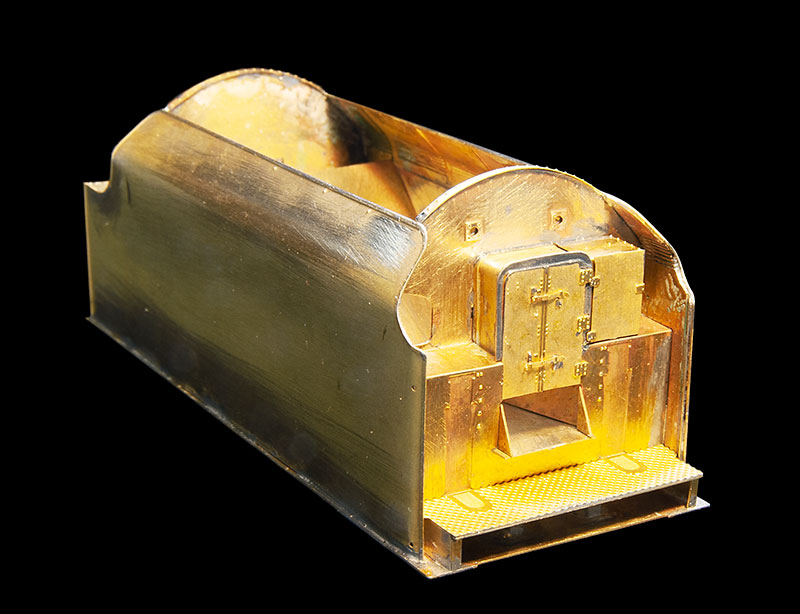

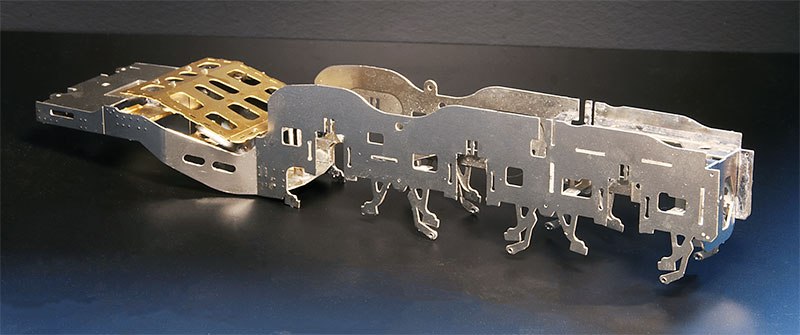

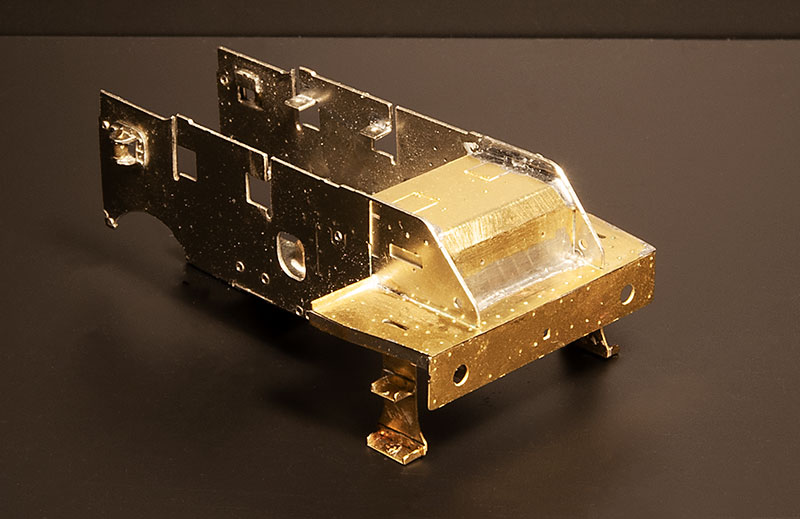

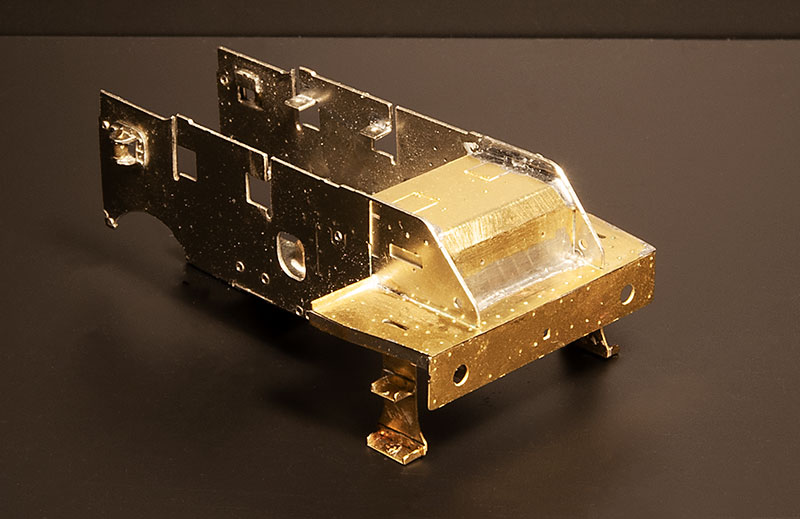

The front or bogie area sub-frame.

More to follow.

I am currently embarked on building a test build of the forthcoming Brassmasters Coronation or Duchess kit. Way before I got distracted with Brettell Road I always thought that if Brassmasters ever did a Duchess i would have a go at building one as 46235 'City of Birmingham'. Well now they are and so I am!

Of course its a personal opinion thing but I never really liked streamlined steam locos. While the Duchesses were a little more thoughtfully designed than the god awful GWR efforts I always thought they looked a bit like an upturned bath tub and have to admit the A4's did look a fair bit better. However with the streamlining taken off the Duchesses were 'it'. The steam locomotive version of the Concorde moment. To my eyes, at least, the pinnacle of steam loco perfection.

Anyway enough hero worship and on to the model. Starting with...

The main sub-frames. The loco frames come in 3 sub sections related to the wheels. A driving wheel section, a pony truck section and a bogie section.

The chassis upside down, test fitting the main coupling rods.

The main frame with the brass overlays fitted.

The front or bogie area sub-frame.

More to follow.