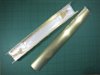

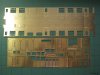

The etched metal parts.

The brass etched bodyshell and roof arrive preformed - which is a huge help. Can you imagine trying to form the complex curves from flat? I haven't unwrapped these, since I don't actually need to touch them until quite a way into the construction sequence. All etched and cast parts are bagged or wrapped. There's nothing loose in the box, not even supplied wire.

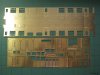

This brass etch is interior and exterior ends, and main gangway components.

This is the brass etch interior shell, dividers, doors and counter area for the RMB.

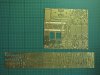

I know. That's what I thought when I saw this! Etched nickel silver detail parts for the body and underframe. Some of these parts are designed to be left "naked" and glued in place at the end of the construction. You can see right away there are data plates, gangway rubbing plates, end steps, and sliding window ventilators, which can potentially be posed as open. Among - many - other parts that I may not recognise until I get to them in the instructions! (There's a BR tail lamp in there. Can you spot it?)

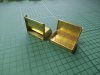

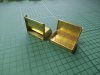

The seating is preformed from brass etch. That's one laborious job I don't have to do!

A seat closeup. You can see how many folds are involved in this single piece of etched brass. You can also see the half-etched relief moquette pattern, which will buff up lovely with some dry brushing.

We're not done with the seats - cast arm rests. The brass pins are for something that will come clear at a later date, I hope.

This nickel silver etch is the interior detail for seating bays. There are six of these sheets in this kit, to give tables, luggage racks, underseat heaters, light fittings and window blinds (open). Again, many of these parts are intended to fitted "naked" near the end of construction to replicate the aluminium castings and fittings on the real thing.

The window frames, etched nickel silver.

A sheet of flexible material is provided so the gangways can be modelled working, just like the real thing. No, really. There is a cutting template provided on one of the etches to make the gangway rain cover, too.

Castings. As I mentioned earlier, all the loose parts are bagged up, generally in sets where there are multiple copies or where items are specific to a model. This lot is the RMB roof detailing. I've written on the bags to remind me what's in where.

A bag of bags of castings. These represent the standard BR roof and end detail castings. I hope you can see how clean these castings are. There is no hint of a mould line, and precious little flash. Perhaps a quick pass with a file to tidy up a moulding gate pip, but I will be willing to bet most of these parts will fit snugly in their location holes without fuss.

That's the topsides. Next, the undersides.

).

).