Progress is slow, but steady. I find I can be a slow starter sometimes.

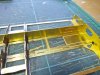

I've been warned to keep an eye on alignments, especially with the cross trusses and subsequent longitudinal framework. I had become aware of the likelihood of problems arising when fixing the first cross member to the main frame web. The following is not meant as criticism, more as highlighting things for other builders.

What is not obvious from the drawings is the cross truss does not stretch the complete way across the floor web. There's a little under a millimetre of free space at each end. The critical thing is to ensure the slots align properly with the half-etch line that runs the length of the web. If misalignment creeps in, distortion and twisting might occur later, which would be the very devil to correct.

View attachment 28085

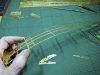

The most obvious thing is to cut out the long truss etch and use to help keep alignment. As a quick alternative, I used one of the cross trusses I had yet to fit - later replaced with a length of scrap etch. This helped me to align the second truss with the first, and with the web.

View attachment 28086

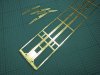

Even now, there's a tiny bit of misalignment that's crept in, because the slots and half-etch still have to be aligned by eye at some stage. I hope, being aware this has happened, I can make sure it doesn't get any worse as the build progresses.

View attachment 28084

Even though I've only fitted eight components so far, the web is already beginning to become stiffer. As the remaining cross trusses go in, I suspect things will get much firmer.

(I can't help it. My inner Kenneth Williams is making noises and sniggering about double entendres.

)

As I said, I'm a slow starter. The first bogie pivot section took me ages. The second one was a lot quicker to fabricate. I hope things will swing along nicely with the rest of the truss work tomorrow, but this afternoon I am switching attention to 57xx.

.

. .

.

)

)