Overseer

Western Thunderer

Dan,

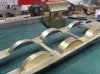

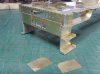

Looks very nice from here and will be very impressive when finished. I think the sheet metal has an edge over cast resin for capturing the subtleties of thin sheet metal cladding. Looking at prototype photos I think you need to increase the radius a bit more - there shouldn't be any vertical face on the firebox front above the boiler top, the radius starts where they meet. Then this radius continues around the shoulders and down the sides to near where the boiler meets the firebox. Not sure if this is a clear description.. I am sure there was plenty of variety but the GWR would have used the same press tool to form this part of the cladding so they would mostly be consistent.

Looks very nice from here and will be very impressive when finished. I think the sheet metal has an edge over cast resin for capturing the subtleties of thin sheet metal cladding. Looking at prototype photos I think you need to increase the radius a bit more - there shouldn't be any vertical face on the firebox front above the boiler top, the radius starts where they meet. Then this radius continues around the shoulders and down the sides to near where the boiler meets the firebox. Not sure if this is a clear description.. I am sure there was plenty of variety but the GWR would have used the same press tool to form this part of the cladding so they would mostly be consistent.