You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm David Andrews Patriot.

- Thread starter MerseyMan

- Start date

Hi Mike. Lovely layout. I'm afraid the Patriot is all I have. However I might try and pop in all the same with my good lady for a nosey if that's OK? I suppose I could bring the Milk Tank and give that a run

Anyway, I wasn't happy with the joint between the Valve spindle and the Radius Rod. The real thing has a forked end which the kit doesn't.

So using a piece of scrap etch I made one up and soldered it on. The whole assembly is now much more sturdier.

One thing I never touched on last time was the 12ba Grub Screw which I've used to hold the Combination Lever to the Valve spindle. I was going to use some brass rod and solder this joint, but as I want to make as much of the motion removable as possible, this method, unlike a screw which wouldn't fit between the Valve guides which will be added next, seemed like the perfect option. I also need to make up/acquire the oiler's for the combination lever from somewhere.

I'm sure this is all pretty basic stuff to everyone else, but for me its really steep learning curve.

Anyway, I wasn't happy with the joint between the Valve spindle and the Radius Rod. The real thing has a forked end which the kit doesn't.

So using a piece of scrap etch I made one up and soldered it on. The whole assembly is now much more sturdier.

One thing I never touched on last time was the 12ba Grub Screw which I've used to hold the Combination Lever to the Valve spindle. I was going to use some brass rod and solder this joint, but as I want to make as much of the motion removable as possible, this method, unlike a screw which wouldn't fit between the Valve guides which will be added next, seemed like the perfect option. I also need to make up/acquire the oiler's for the combination lever from somewhere.

I'm sure this is all pretty basic stuff to everyone else, but for me its really steep learning curve.

With only the spare odd hour here and there, I made a start on the "Face" of the locomotive. I'm amazed at how cruel the camera can be to the surface of the whitemetal casting, not to mention my soldering. The lamp bracket is a casting from Laurie Griffin replacing the Etched version from the kit. The Handrails are made up of 0.7mm Brass tube with two of Suzanne's Brass Dress maker pins for the ends. These were filled down so that they would fit inside the brass tube. The whole lot is only a friction fit at the moment for photographs so the final fit will be much better. I might see about replacing some of the cast on "Nuts" with ones from Scale Hardware depending if I have enough left.

Ian@StEnochs

Western Thunderer

Neat solution! I have used slivers of tube over the ends of the wire to form the buttons but never thought to do it your way. Inspired. Where do you source the tube?

Ian.

Ian.

The build has taken a slight step back in that I wasn't happy with the backhead which was 90% completed way back in post 5#. I couldn't get the firebox door mechanism to sit right, nor could I devise a method to make the whole whitemetal casting removable from the loco. So I started to play with the idea of scratch building a set of working sliding doors. After an evenings work, here is the result mounted to a heavily modified brass backhead from Laurie Griffin. It still needs a proper clean up but you get the idea. I will secure the backhead to the loco by passing a screw through the firehole with a nut in the back of the firebox. The screw head will be hidden by simply shutting the doors. The two oversized screw heads will be replaced with proper ones once its all painted up.

The next job will be to transfer the fittings across from the completed whitemetal backhead to this new one.

The next job will be to transfer the fittings across from the completed whitemetal backhead to this new one.

I have just done that on a 5 inch gauge build,and it was not easy getting it all opening and shutting all square,and as those pictures show it much bigger than it is in 7mm scale,im impressed ,very impressed,wish i could do it in this scale,you should be very proud of your work

warren haywood

Western Thunderer

It should work with airbrushed cellulose, I get loads of locos with sliding windows and they work fine after a layer of psint

Lancastrian

Western Thunderer

Although the actual locomotive is progressing very slowy, with a few hours here and there I've started making up the smaller detailing parts. I noticed the kit doesn't include the clasps for the cylinder drain taps so I made a couple up using some scrap etch and a couple of scale hardware's dummy bolts. As I'm modelling a early BR Pat, the pipes still need to be cut to length.

View attachment 52490

View attachment 52491

I wasn't happy with the "cast" brass pipes so I tried to find some one who supplies 0.6mm copper tube for the cylinder drain tap pipework. I found one company but at nearly £200 a metre I decided to give it a miss. Giving up on the Copper tube idea, I ordered some 0.8mm copper wire but being solid, they still didn't look right. So with afew choice words, and a couple of burnt fingers I managed to drill them out using a 0.4mm drill. It doesn't run the full length but it still gives the impression it's a pipe rather than wire (or at least I hope it does).

View attachment 52492

I know it's a bit late now, but Chronos Ltd can supply 0.8mm brass tube with a 0.4mm inside bore.

Albion Alloys Brass Micro Round Tube Metric

Ian

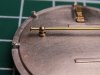

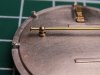

Wow, I can’t believe it’s been nearly two years since I last posted an update. With life getting in the way, I still haven’t finished the Patriot. Although it is now starting to look like a loco. Since the last post I have built the bogie, largely from scratch as the one supplied in the kit was rubbish. The side Springs and bolster are from Ragstone while the Axleboxes are LSWR ones from Laurie Griffin. They’re probably not 100% correct for a Patriot but they come close enough for me. I still need to add afew more things before it will get a good clean up.

And the underside ...

Although the loco is still progressing, for a while it was a case of 1 step forward and 2 back. The original motion brackets supplied in the kit are completely rubbish so I ordered a set of Griffin Jubilee ones. But these were also rubbish so I ended up using a pair from JLTRT. It took me awhile to integrate them into the exisiting “box assembly” which I wanted to retain but I got there in the end. This allowed me to then add the Valve guides. I also replaced the crappy kit combination lever which was letting the side down with one from Premier components. These are supplied not fluted so many thanks to David LO Smith who done a cracking job of fluting them for me. The oil boxes was also missing so I soldered a piece of 1mm bar on and then filed to shape, finishing it off with a simulated bolt from scale hardware.

As mentioned in a previous post the return cranks are too long which puts the Eccentric rod at an incorrect angle. So I made some new ones to the correct length. While I was there I also gave the 4 retaining nuts a little bit more detail by using actual nuts on threaded bar rather than the simulated ones from SH.

I then went abit mad and did the same to the expansion link.

I then assembled the footplate and added the firebox so this is were we are currently at.

I gave the firebox corners a quick dusting of primer to make sure I had shaped them corrected as its quite hard to tell when bare shiny metal. It all needs a proper clean so my apologies for the excess solder and shoddy finish.

And the underside ...

Although the loco is still progressing, for a while it was a case of 1 step forward and 2 back. The original motion brackets supplied in the kit are completely rubbish so I ordered a set of Griffin Jubilee ones. But these were also rubbish so I ended up using a pair from JLTRT. It took me awhile to integrate them into the exisiting “box assembly” which I wanted to retain but I got there in the end. This allowed me to then add the Valve guides. I also replaced the crappy kit combination lever which was letting the side down with one from Premier components. These are supplied not fluted so many thanks to David LO Smith who done a cracking job of fluting them for me. The oil boxes was also missing so I soldered a piece of 1mm bar on and then filed to shape, finishing it off with a simulated bolt from scale hardware.

As mentioned in a previous post the return cranks are too long which puts the Eccentric rod at an incorrect angle. So I made some new ones to the correct length. While I was there I also gave the 4 retaining nuts a little bit more detail by using actual nuts on threaded bar rather than the simulated ones from SH.

I then went abit mad and did the same to the expansion link.

I then assembled the footplate and added the firebox so this is were we are currently at.

I gave the firebox corners a quick dusting of primer to make sure I had shaped them corrected as its quite hard to tell when bare shiny metal. It all needs a proper clean so my apologies for the excess solder and shoddy finish.

Last edited:

While I was studying photo's of the brake hangers, I noticed 45509 has some kind of webbing between the 3 spokes nearest to the crankpin which can be seen in the picture below.

It seems some but not all of the Patriots had them. I would like to add these if I can but I as there are 3 per wheel I don't particular fancy cutting and shaping them from brass sheet. Therefore I was wondering if anybody has done this before and if so recommend an easier way of making them. Or even if any etches are available on the market?

It seems some but not all of the Patriots had them. I would like to add these if I can but I as there are 3 per wheel I don't particular fancy cutting and shaping them from brass sheet. Therefore I was wondering if anybody has done this before and if so recommend an easier way of making them. Or even if any etches are available on the market?

Last edited:

Steph Dale

Western Thunderer

I've had to do those on a few German HO locos. I used superglue to stick a suitably shaped blank to infill the gap between the spokes and then cut the hole out once cured. If the superglue is allowed to form a fillet it'll look like part of the wheel casting with no effort.

Steph

Steph

Hi Rodger,

Yes I think so as the picture depicts 5619 in as built condition. I'm building 45509 in early 50s condition which has Stanier pattern wheels. However the webbing around the crankpins appear to be the same. It was just this was the best picture I could find which shows the webbing clearly.

This is an actually close up of 45509 with the the Stanier Pattern wheels. You can just make out the webbing between 3 sets of spokes.

Yes I think so as the picture depicts 5619 in as built condition. I'm building 45509 in early 50s condition which has Stanier pattern wheels. However the webbing around the crankpins appear to be the same. It was just this was the best picture I could find which shows the webbing clearly.

This is an actually close up of 45509 with the the Stanier Pattern wheels. You can just make out the webbing between 3 sets of spokes.

Last edited: