You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Dikitriki's Dark side: A WD 2-8-0

- Thread starter Dikitriki

- Start date

mickoo

Western Thunderer

+1,Lovely...!

I must admit, I've never used a micro flame for any 'building' other than stripping down and using for soldering up crank axles... Anyone proficient with one fancy creating a thread on how to use for the finer side of things?

JB.

I struggled last night fixing something to the A3 boiler and thought a microflame might have worked better in getting more heat in quicker and cleaner. It may also be something to do with this new reel of solder I have, it's just too viscous and prefers to stick to the tip rather than the work.

7mmMick

Western Thunderer

Not wanting to intrude on Richard's thread, but I swear by my microflame. I think I paid about three quid for it from eBay about four years ago and it's still going well. It will do most things, as long as the parts fit well and are clean away you go. You just have to be careful with heat and think about whether you'll distort anything or like Richard says other bits will drop off as the heat tracks along joints etc. You can even attach some white metal castings to brass etch but the margin for error here is small.

Mick

Mick

Dikitriki

Flying Squad

Hi,

I have to say I'd be lost without my microflame. The whitemetal fittings on the crab boiler were attached with it. I also dismantled Scanlon's 76000 firebox which meant taking the spigoted lost wax brass castings off a thin white-metal firebox. That was quite nerve-wracking as I wanted to reuse the firebox.

I shall do some videos on how I use the microflame as and when I have to use it next. There are some key characteristics for me when looking at microflames. Genuine one-handed use which means auto ignition, adjustable flame, visible gas reservoir, pen-type rather than upright. I use a Nimrod Solderpro120 and would replace it like for like if it failed.

Yesterday I fitted the exhaust steam injector, though not yet the large pipe and grease separater. That was enough as there is constant checking of bends and levels for fit. It didn't help that I discovered the rear of the chassis is the wrong shape, but it's too late for me to do anything about that, and it's not really noticeable. It just meant that a couple of pipe runs were slightly out. But hey, you wouldn't have noticed if I hadn't told you.

Both ejectors have been clipped to the steps so everything is very solid

It's getting pretty crowded under there!

Got to remember to replace the rear crankpin nuts

There's a bit of filling needed on the live steam injector arising from switching the overflow pipe.

I shall have to locate my stock of grease separaters before I can do more, so it's on to the cab and the AWS bits. More poring over pictures.

Richard

I have to say I'd be lost without my microflame. The whitemetal fittings on the crab boiler were attached with it. I also dismantled Scanlon's 76000 firebox which meant taking the spigoted lost wax brass castings off a thin white-metal firebox. That was quite nerve-wracking as I wanted to reuse the firebox.

I shall do some videos on how I use the microflame as and when I have to use it next. There are some key characteristics for me when looking at microflames. Genuine one-handed use which means auto ignition, adjustable flame, visible gas reservoir, pen-type rather than upright. I use a Nimrod Solderpro120 and would replace it like for like if it failed.

Yesterday I fitted the exhaust steam injector, though not yet the large pipe and grease separater. That was enough as there is constant checking of bends and levels for fit. It didn't help that I discovered the rear of the chassis is the wrong shape, but it's too late for me to do anything about that, and it's not really noticeable. It just meant that a couple of pipe runs were slightly out. But hey, you wouldn't have noticed if I hadn't told you.

Both ejectors have been clipped to the steps so everything is very solid

It's getting pretty crowded under there!

Got to remember to replace the rear crankpin nuts

There's a bit of filling needed on the live steam injector arising from switching the overflow pipe.

I shall have to locate my stock of grease separaters before I can do more, so it's on to the cab and the AWS bits. More poring over pictures.

Richard

Dikitriki

Flying Squad

...Nimrod Solderpro120.... looks like a purchase forthcoming

I've just had a look on-line Mick. They are now branded Iroda, rather than Nimrod.

Edit: that might be for the US market, Nimrod (seems identical) here http://www.nimrodeuropedirect.com/?opt=item&id=93

Richard

Last edited:

Heather Kay

Western Thunderer

I just checked, and Richard is correct. I found one on Amazon but sold via Maplin. I bet they don't have them in their stores!

mickoo

Western Thunderer

Cheers guys, found this on Ebay

http://www.ebay.co.uk/itm/400756341658?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

Bit more expensive than other places but includes several bits and goodies, not sure if I need all of them or just the torch and take the tip out.

http://www.ebay.co.uk/itm/400756341658?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

Bit more expensive than other places but includes several bits and goodies, not sure if I need all of them or just the torch and take the tip out.

Rob Pulham

Western Thunderer

Mine's an Iroda and it's been going strong for a few years now - I only paid about £35 for it so I would look around if I were you Mick.

SimonT

Western Thunderer

I bet they don't have them in their stores!

The Swindon store presently has two in stock. Obviously about to become one

.

.Simon

Steph Dale

Western Thunderer

I note that Nimrod are due to be at the ALSRM show at Reading on Saturday...

Dikitriki

Flying Squad

Hi

I've had a short break of late - we took ourselves off to Bude, and I communed with my JLTRT Presflos which moved on a tiny bit - so not too much has happened on the crab of late. What I have managed to do is prepare some of the AWS gear.

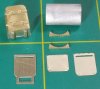

The battery box is a butchered Ragstone casting designed to fit a Duchess, the tank is a Ragstone casting, the tank supports are fashioned from some thick brass strip and the coupling protection plate is from the scrap box. It will probably be Sunday before I can get to fit them.

Richard

I've had a short break of late - we took ourselves off to Bude, and I communed with my JLTRT Presflos which moved on a tiny bit - so not too much has happened on the crab of late. What I have managed to do is prepare some of the AWS gear.

The battery box is a butchered Ragstone casting designed to fit a Duchess, the tank is a Ragstone casting, the tank supports are fashioned from some thick brass strip and the coupling protection plate is from the scrap box. It will probably be Sunday before I can get to fit them.

Richard

Dikitriki

Flying Squad

Hi

I have now fitted the fireman's side AWS gubbins, along with some scratchbuilt electrical cabling and appropriate brackets. I obtained a full set of AWS components from Ragstone - I hadn't realised there were so many bits!

I've also drilled a hole (series of holes filed through actually) through the footplate for the lubricator drive arm - also a Ragstone casting. The previous drive arms had terminated a little above the footplate

Richard

I have now fitted the fireman's side AWS gubbins, along with some scratchbuilt electrical cabling and appropriate brackets. I obtained a full set of AWS components from Ragstone - I hadn't realised there were so many bits!

I've also drilled a hole (series of holes filed through actually) through the footplate for the lubricator drive arm - also a Ragstone casting. The previous drive arms had terminated a little above the footplate

Richard

oldravendale

Western Thunderer

Lovely stuff Richard. One of my favourite prototypes - so ugly they are beautiful.....

Brian

Brian

Dikitriki

Flying Squad

Yeah, that's what I thought until I discovered it was cast nickel-silverThat w/m? whistle looks like it could be a bit vulnerable?

OzzyO.

Really odd that

Really odd that

Richard

Len Cattley

Western Thunderer

Fantastic work there Richard.

Len

Len

Dikitriki

Flying Squad

Gosh, last post here over a year ago. Still, I have been distracted by Finney7, Gauge 1, and a garden railway. I still get nagged by the group to finish the crab off though.

My recent 7mm scale work has been to construct 2 turnouts.

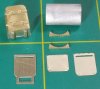

The top one is from a Templot template, B6 to 31.5mm gauge, the bottom one is a C&L B6 point in a bag to 32mm. These are for the GOG technical committee who are building a little comparison test bench with all pointwork from Peco Setrack to S7 I think. Hopefully we can demonstrate that finescale chassis do not have to be rebuilt to go through 31.5mm pointwork

Richard

My recent 7mm scale work has been to construct 2 turnouts.

The top one is from a Templot template, B6 to 31.5mm gauge, the bottom one is a C&L B6 point in a bag to 32mm. These are for the GOG technical committee who are building a little comparison test bench with all pointwork from Peco Setrack to S7 I think. Hopefully we can demonstrate that finescale chassis do not have to be rebuilt to go through 31.5mm pointwork

Richard