P A D

Western Thunderer

I received my order of 1.2mm NS rod so replaced the originals which were from the curved length of NS rod supplied with the kit. They weren't 100% straight and I'd cut them too short, as as the back of the stroke the ends were inside the stuffing gland.

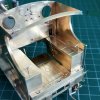

On the main handrail I took a leaf out of Dikitriki's book and added the smokebox section first. The lengths that run along the boiler are fed in through holes in the cab and then passed through the pillars up to the ones on the sides of the smokebox. On on the right hand side there is a valve rather than a pillar.

Here's how the hand rails are fed into the pillars through the cab front plate. They will be trimmed to length and fitted after painting and secured with a dab of super glue.

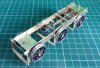

The rear steps are on a spacer that is supposed to fit loosely on top of the frames at the rear. The injectors and pipework are also fixed to this spacer. When the body is placed on top, the three units are bolted together. I didn't see the point of this and it seemed a fiddle when removing ghd chassis from the body, so I opted to solder the steps, spacer and injectors etc to the underside of the cab. The supports for the feed pipes were part of the rear chassis spacer, so I cut them of and fixed them to the drag beam, with a piece of waste etch. They need a bit of filling to hide the joint.

The front steps are fixed to the slidebar bracket as per the instructions.

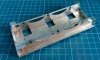

The cylinder wrappers and draincock were added at the same time.

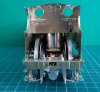

Here they are in place

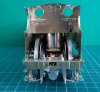

T'other side.

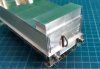

And some views of the current state of play. The housing for the rear end of the reversing rod has now been added.

A broadside with the left handrail in place. Looks like the oil pot bracket has taken a knock.

Cheers,

Peter

On the main handrail I took a leaf out of Dikitriki's book and added the smokebox section first. The lengths that run along the boiler are fed in through holes in the cab and then passed through the pillars up to the ones on the sides of the smokebox. On on the right hand side there is a valve rather than a pillar.

Here's how the hand rails are fed into the pillars through the cab front plate. They will be trimmed to length and fitted after painting and secured with a dab of super glue.

The rear steps are on a spacer that is supposed to fit loosely on top of the frames at the rear. The injectors and pipework are also fixed to this spacer. When the body is placed on top, the three units are bolted together. I didn't see the point of this and it seemed a fiddle when removing ghd chassis from the body, so I opted to solder the steps, spacer and injectors etc to the underside of the cab. The supports for the feed pipes were part of the rear chassis spacer, so I cut them of and fixed them to the drag beam, with a piece of waste etch. They need a bit of filling to hide the joint.

The front steps are fixed to the slidebar bracket as per the instructions.

The cylinder wrappers and draincock were added at the same time.

Here they are in place

T'other side.

And some views of the current state of play. The housing for the rear end of the reversing rod has now been added.

A broadside with the left handrail in place. Looks like the oil pot bracket has taken a knock.

Cheers,

Peter