Back in France and some more progress has been made on the tender. I have also re-read the story of 46235's preservation in Andrew Roden's paperback The Duchesses. The Museum of Science and Industry, then on Newhall Street, first started to enquire about 46235 in 1954 and negotiations commenced in 1959. BR wrote a letter at this time stating that the locomotive had a further 10 years to run, basically implying that steam traction would last up until electric traction took over. This also meant that the museum could be extended to receive the locomotive. We now know that this timetable was not to last for long.

46235 was withdrawn in October 1964 and was moved to Nuneaton for storage in January 1965. Nine months later she returned to Crewe for a cosmetic overhaul which took until May 1966 to complete. The loco was then moved to Saltley Shed and then by road to the museum site.

This chain of events explains why the loco had been photographed at Nuneaton

with the yellow stripe, so another puzzle solved!

Andrew Roden goes to some length to question why the cosmetic overhaul took so long. The obvious answer is that there were other priorities at Crewe Works. The intriguing idea, though, is how detailed the overhaul might have been, 4073 Caerphilly Castle being cited as an example of pride of ownership by the men at Swindon before that locomotive was "plinthed" in the Science Museum.

Personally I doubt that the overhaul was anything more than cosmetic. My main evidence for this comes from examining the present condition of 46235.

Before resuming the modelling, I just want to say this about the preservation of 46235. I used to think that there could be nothing better than seeing the locomotive running again with all the necessary modifications for modern main line certification. I don't think this any more. But what I would like to see is the locomotive given more space in the museum environment, have the tender close coupled again, like it was in Newhall Street, and even have the electric motor re-installed so that people could see the valve gear move once again.

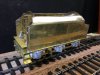

And now a photograph, showing some progress on the tender!

I am in the process of putting together the steam coal pusher components, partly visible in the photo.

The sun is shining in a blue sky at the moment so I doubt if much more progress will be made today!

Paul