mickoo

Western Thunderer

Having a bit of spare time last week I decided it was time to make good a promise to a colleague and do something with all the drawings he'd sent some time ago.

Naively I figured it'd just be a simple tweak here and there from the last NER tank, err no! It ended up being almost all needing changing. Being lazy and quite honestly useless at cutting parts out I've added lots of the simple shapes, I'd rather pay the bit extra and take the cusp off than try to cut straight and to size and then get cross

So a few days in CAD and it spat out the etches which were duly sent off for processing.

This week the labels were added so once back, work can begin on the test build with no further ado.

The only parts missing are the boiler sheet and formers, I've little issue cutting those and the above represents a late BR engine with small boiler and smoke box (but extended). The other options, and there are a few of them, will be better served with small supplementary sheets later.

The only problem now is it'll take a week or more to return and I've got itchy CAD fingers already

Naively I figured it'd just be a simple tweak here and there from the last NER tank, err no! It ended up being almost all needing changing. Being lazy and quite honestly useless at cutting parts out I've added lots of the simple shapes, I'd rather pay the bit extra and take the cusp off than try to cut straight and to size and then get cross

So a few days in CAD and it spat out the etches which were duly sent off for processing.

This week the labels were added so once back, work can begin on the test build with no further ado.

The only parts missing are the boiler sheet and formers, I've little issue cutting those and the above represents a late BR engine with small boiler and smoke box (but extended). The other options, and there are a few of them, will be better served with small supplementary sheets later.

The only problem now is it'll take a week or more to return and I've got itchy CAD fingers already

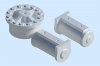

but this one, a very small section from a large format neg of Q6 63435 shows the cylinder front rather well, I thought.

but this one, a very small section from a large format neg of Q6 63435 shows the cylinder front rather well, I thought.

certainly not.

certainly not.