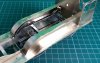

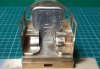

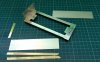

The cab front plate and firebox back have now been modified to accept 10BA screws to fix them together. First the firebox back was thickened up with an extra layer of brass plate soldered on the inside. The holes in the cab front plate were then drilled to clear 10 BA and then with the firebox in place, the holes for tapping were marked. I cocked up the position for the upper hole and had to redo it. After drilling the holes in the back of the firebox, they were then tapped 10BA to accept the fixing screws. I much prefer doing it this way than soldering nuts in place as it is far more robust .

The cab roof has also been completed with the addition of the rain strips.

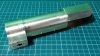

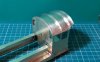

Moving back to the boiler, the smoke box door casting was fettled up. Here's how it started out.

Rubbing it down avoiding the rivets was tiresome, so I marked their positions with a point and rubbed them off. After the door was smooth enough I drilled holes for the rivets and and replaced them with items from Prime Miniatures. After fitting the handrail, I found it was sloping so the hole for the pillar opposite the hinge was elongated to move it upwards. I need to add a little filler to disguise it. The rivets, door handle and hand rail pillars were all super glued on the inside, so no cleaning up was required.

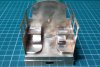

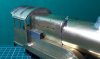

Here's the inside of the door casting. I decided to make if removable by making a simple " bayonet" fitting by cutting two slots opposite each other, top and bottom and then splaying out the sections between the cuts. One of them showed signs of cracking so this was repaired with solder.

On the smoke box front ring, two slots were filed at 3 and 9 o'clock. The door is then slotted in and twisted 90 degrees to lock it in place. This will allow the owner access for fitting steam sound if desired.

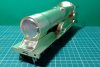

Finally, the chimney and dome have been epoxied in place. In this image, the door casting has been twisted too much so the handrail is not level.

The semi cured epoxy that oozed out from under the castings has been scraped away, but further tidying up will be done later.

Starting to look the part with the furniture on.

Cheers,

Peter