The water scoop which is a 3 part casting was epoxied together before fitting. Easy enough to do but when you come to fit it to its location point on the middle frame spacer, the fun starts. Even with relatively small fingers I found it impossible to locate it under the brake rigging and hold it to solder in place from above. Epoxying would also have been a pain, so I cut off the locating pin and drilled and tapped it 6 BA. I was then able to screw it in place.

Once is was lined up I soldered thr screw and casting rather than relying on the threads in the white metal.

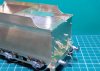

To complete the detailing at the rear end ghd guard irons were added along with the stowage chain for the steam pipe.

And at the front I made the cruciform fire iron bracket from 0.9 mm nickel silver rod. The handle on the brake standard was too low, so I cuf it off and replaced the stem with a longer piece of rod to raise it. When I receive the ships wheel that Tony Geary is kindly sending me, I will fit it in place of the etched one.

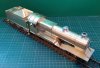

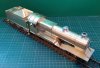

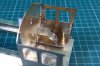

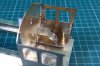

So back to the loco. At the front I drilled through the valve chest cover und running plate and soldered a short length of tube to support the brake pipe casting. It's a firm push fit but can be removed for painting then glued in afterwards. The footstep on the cover has also been fitted.

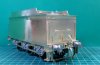

On the boiler the hand rail pillars have been fitted, but the rail has been left loose to fit after painting, apart from the section around the smokebox.

On the left hand side there is a gap in the rail where a casting who's name escapes me will fit, and there are two extra pillars. The footstep on the smokebox front ring has also been fitted.

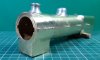

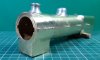

The ejector pipe is just a length of brass rod located into a ho,e in the smokebox and cab front plate. There is a flange at the front whichI made from waste fret.

And a closer view of the flange.

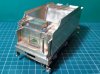

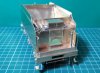

Again, as an aid to the painting/lining of the cab sides, the grab rail is just a push fit into the locating holes. To increase the purchase of the rail in the thin etch cab sides, 16 BA nuts were located on the inside and held with a sharpened cocktail stick for soldering. They were then drilled through to suit the rod size.

And wit the grab rail located.

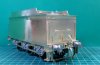

Here's a couple of views with the handrails and ejector pipe in place

The loco footsteps have now been fitted as have the grab rails above the forward steps.

Cheers,

Peter