So, back at the bench this afternoon, I have now completed the 11F build. As it will be painted in GCR livery, it's more appropriate to use the GC classification. Larry Goddard raised some doubts about the shape of the chimney earlier in the build, that until then I hadn't realised.

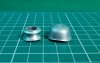

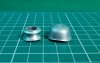

It got me looking closer at the loco and the dome also did not look right. Following contact with David Hill at Gladiator, he offered to send me an alternative chimney and dome when he briefly returned to the UK from the far east. This is what he sent me. The dome looked pretty close to the prototype, but the chimney was too tall and the wrong profile. However, I felt I could fettle the chimney into something more acceptable than the one already fitted.

Here's the dome after tidying up and the chimney after modification. Not having a scale drawing to work with, the chimney is not 100% accurate, but in my opinion is far closer to the prototype than the one supplied with the kit. About 1mm was removed from the height by sawing it in two about half way down, then carefully rubbing down the parts on emery paper until I was satisfied with the height. The two halves were the lined up on a piece of dowel and joined with low melt solder. Using the dowel as an arbor, I reprofiled the chimney in the lathe using files, emery paper and scratch brush. Some of the work was done off the lathe by hand, mainly reducing the diameter of the base and chimney cap. The chimney has quite prominent fixings so I drilled the base ready to accept brass rivets after epoxying to the smokebox.

Once I was happy with the replacements, I set about removing the existing chimney and dome, which involved some butchery. Both had been epoxied in place, which some modellers have reservations about. Over the past 30 years I have epoxied dozens of chimneys, domes and other fittings to various model locos and none have ever come of due to handling or deterioration of the epoxy. Using epoxy gives time for adjustments and any excess is easy to remove if done when it is part cross linked. As to the physical robustness, here's what I had to do to get them off. First I made a cross cut with a junior hacksaw and in the case of the chimney, then gripped the segments with a pair of pliers one at a time and bent them outwards to break the glue joint. Here's the chimney with the first segment removed.

The dome, being a solid casting, needed a little more effort to remove. As well as a watch maker's vice (Burgeon copy), I have a swivelling multi angle Stanley vice. It's no good for precision work, but great for larger stuff. I used this with the soft jaw covers to hold the boiler whilest sawing the cross cut in the dome.

After making the cuts, I then drilled through the casting centre with a drill big enough to allow insertion of a pair of pliers and then gripped the segments as before and bent outwards to brake the glue joint. Worked a treat in both cases with no damage to the brass.

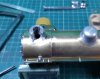

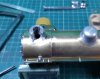

Here are the dome and chimney after fitting. After the chimney was cleaned up, I drilled through the pre drilled holes in the base into the smokebox and added the rivets with superglue. If you look closely, you can just discern the joint in the chimney.

So that's it completed and ready to go to Warren Haywood for painting and lining. I'm away from home tomorrow and Friday, so if you read this Warren, I'll give you a shout next week to arrange to bring it over.

Some gratuitous views to finish off.

Remember, a lot of the fittings including the smokebox front casting are loose to assist the painting and lining, so anything not quite straight in the photos, will be later on.

Thanks to all who have made helpful comments throughout the build and to David Hill at Gladiator for getting the missing items and replacement parts to me in double quick time.

Cheers,

Peter

so I didn't bother with the other one. It may be possible to mill out the groove, but I don't have a mill or the skill to use one. The filing is on the inside of one of the rods so doesn't show, but I thought it was worth a try.

so I didn't bother with the other one. It may be possible to mill out the groove, but I don't have a mill or the skill to use one. The filing is on the inside of one of the rods so doesn't show, but I thought it was worth a try.