Dave

Western Thunderer

There's nothing special here, or anything you don't already know about building brass kits, but I'm posting this simply to prove that I actually build the stuff I post in the gallery and that I don't have someone build it all for me (I wish I could afford to!) or have the magic loco kit fairies visit, so here is my current work-in-progess...

It's an Agenoria Models kit of what the blurb describes as an Italia class Hudswell Clarke, although I can find no loco so named in the works list contained in Ron Redman's book The Railway Foundry Leeds 1839-1969.

The kit is meant to build into the WC&P's Walton Park and is provided with name plates, but I'm not modelling the WC&P so my loco will be an anonymous version and, possibly, with a few alterations to suit other locos of the type that I have seen in photos in various books.

Rivets dimpled out, buffer beams soldered on, overlays for springs soldered on and springs bent up.

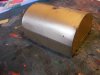

Cab assembled. I'm using resistance soldering for the first time and I'm impressed with how little cleaning up is neccessary. This picture is as put together - no cleaning has been done at all in this pic.

Screws to fix frames to bodywork soldered in and cab fitted to running plate.

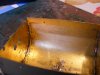

I was going to build the saddletank but the wrapper is missing from the kit. I've sent an email off and am awaiting a response.

It's an Agenoria Models kit of what the blurb describes as an Italia class Hudswell Clarke, although I can find no loco so named in the works list contained in Ron Redman's book The Railway Foundry Leeds 1839-1969.

The kit is meant to build into the WC&P's Walton Park and is provided with name plates, but I'm not modelling the WC&P so my loco will be an anonymous version and, possibly, with a few alterations to suit other locos of the type that I have seen in photos in various books.

Rivets dimpled out, buffer beams soldered on, overlays for springs soldered on and springs bent up.

Cab assembled. I'm using resistance soldering for the first time and I'm impressed with how little cleaning up is neccessary. This picture is as put together - no cleaning has been done at all in this pic.

Screws to fix frames to bodywork soldered in and cab fitted to running plate.

I was going to build the saddletank but the wrapper is missing from the kit. I've sent an email off and am awaiting a response.