allegheny1600

Western Thunderer

Hi All,

"Scattergun" certainly seems appropriate for what I will be posting here as my interests are rather wide ranging. Although principally a H0 modeller, I do work in other scales - 4mm P4 for my Western Region diesel hydraulics and "00" for my local club which is Leigh MRC.

We meet on Tuesday and Thursday evenings and we have decided to whip ourselves into shape by turning our library in a library/modelling room, we can get just 4 people working in there.

Our main layout is now "Bickersleigh", a 00 gauge colliery layout inspired by some of the many former collieries in the area, sadly all gone now except Astley Green colliery museum.

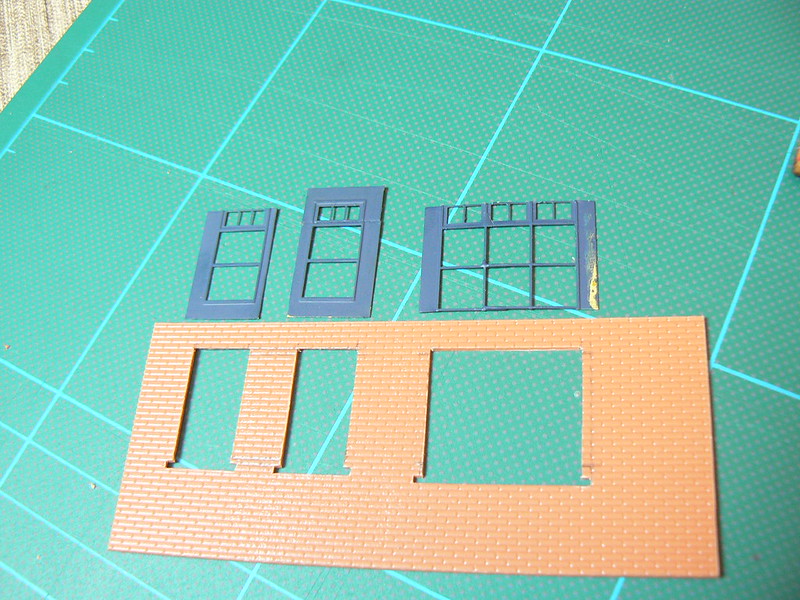

Anyway, a while back I volunteered to build the managers offices seen here;

(marked with an X)

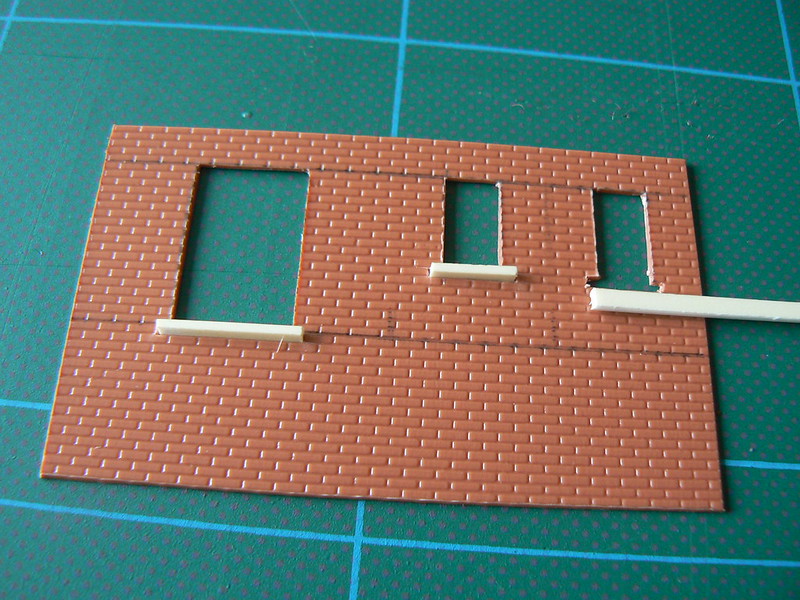

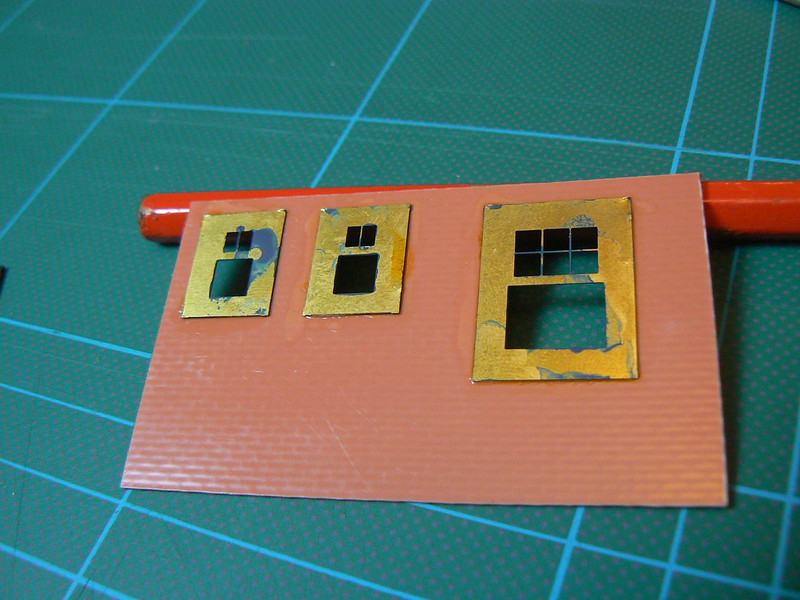

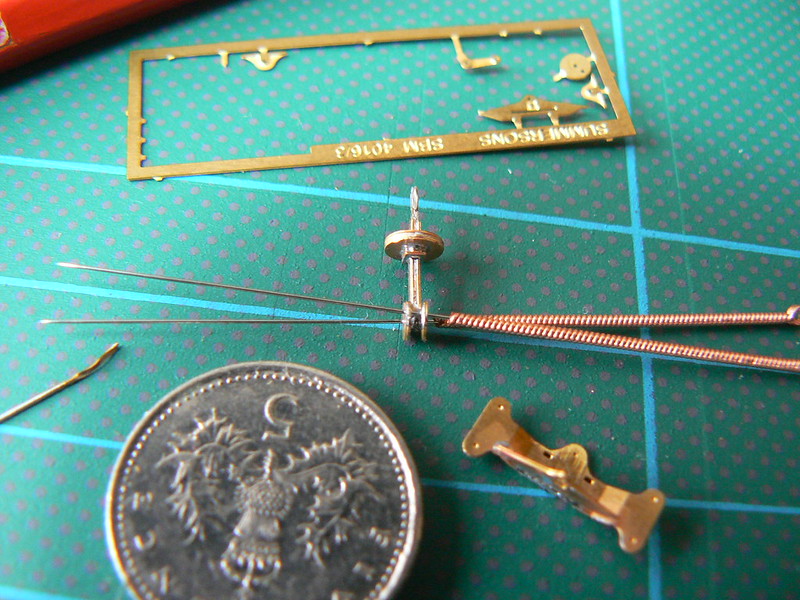

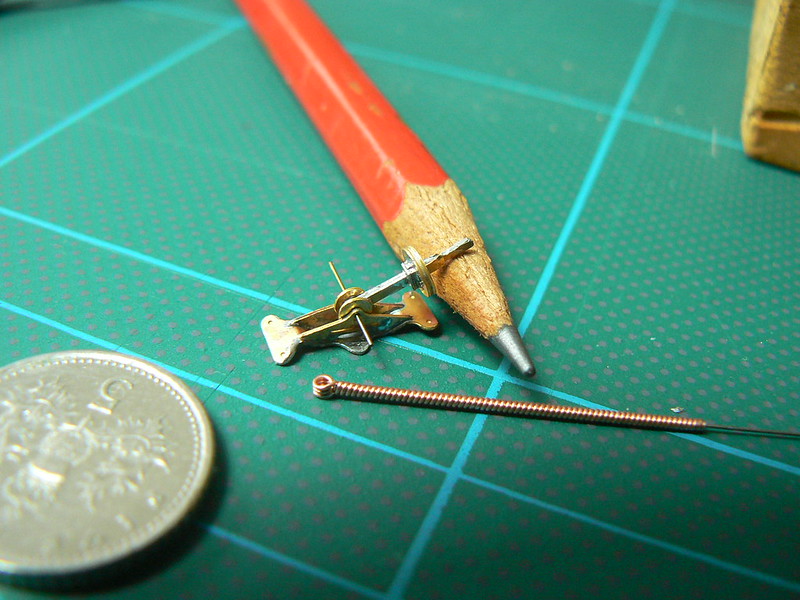

After several weeks work and two attempts, I had (so slowly) built this;

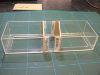

Unfortunately I felt this was too flimsy so recently I decided to start a third time, now using thin perspex.

To be continued.

"Scattergun" certainly seems appropriate for what I will be posting here as my interests are rather wide ranging. Although principally a H0 modeller, I do work in other scales - 4mm P4 for my Western Region diesel hydraulics and "00" for my local club which is Leigh MRC.

We meet on Tuesday and Thursday evenings and we have decided to whip ourselves into shape by turning our library in a library/modelling room, we can get just 4 people working in there.

Our main layout is now "Bickersleigh", a 00 gauge colliery layout inspired by some of the many former collieries in the area, sadly all gone now except Astley Green colliery museum.

Anyway, a while back I volunteered to build the managers offices seen here;

(marked with an X)

After several weeks work and two attempts, I had (so slowly) built this;

Unfortunately I felt this was too flimsy so recently I decided to start a third time, now using thin perspex.

To be continued.