SimonME30

Member

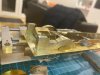

Wish me luck, I’ve had this kit for a few years, and the reviews aren’t promising. An aide to scratch building is all that it’s supposed to be, and I’ve done some of that previously...so this is my COVID-19 project. I’ve had a reasonable search, but not come up with anybody else’s build, so if there is one documented out there please point me in the right direction.

I’m armed with a Yeadons register, the brief instructions do include drawings, and I have decided on 69434 as there is a photo of the loco at Bradford (Exchange), it was allowed to Bradford from 24/6/1951-27/1/57 and scrapped 10/3/1959 from Copley Hill. So a high chance of being caught at Bradford (Exchange) during my 1954-1959 Modelling period.

I’m interested in operations rather than exacting model engineering, and I’m heading for battery powered/radio control. It will be a rigid chassis, as I’m not worried about pickups, and my other rigid chassis builds seem fine on my layout.

I’m posting in the hope that a) I’ll be half kept honest to keep progressing, and b) helpful suggestions will be offered!

Pics to come as soon as I work that out on the iPad...

I’m armed with a Yeadons register, the brief instructions do include drawings, and I have decided on 69434 as there is a photo of the loco at Bradford (Exchange), it was allowed to Bradford from 24/6/1951-27/1/57 and scrapped 10/3/1959 from Copley Hill. So a high chance of being caught at Bradford (Exchange) during my 1954-1959 Modelling period.

I’m interested in operations rather than exacting model engineering, and I’m heading for battery powered/radio control. It will be a rigid chassis, as I’m not worried about pickups, and my other rigid chassis builds seem fine on my layout.

I’m posting in the hope that a) I’ll be half kept honest to keep progressing, and b) helpful suggestions will be offered!

Pics to come as soon as I work that out on the iPad...

) take the coupling rods off and run the chassis along by hand, if it's still tight then it'll be a wheel/bearing issue, if it's free, then there's a very high chance it'll be crank pins or coupling rods.

) take the coupling rods off and run the chassis along by hand, if it's still tight then it'll be a wheel/bearing issue, if it's free, then there's a very high chance it'll be crank pins or coupling rods.