You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Silverystreaks

Western Thunderer

Well it offers an alternative for you to consider Peter, it all depends on how closely you wish to replicate the prototype. I had already applied the procedure to a DJH A1 and as it worked when the MF A3 was being constructed it seemed a simple solution.

An alternative would be to attach the reversing rod to the chassis rather than the running plate but depending on the valve gear setting the reversing rod fore and aft movement would require a degree of access through the running plate and into the lower firebox area. That I imagine could be problematic when it comes to marrying the body to the chassis

Re the Slide Bar bolt head detail, yes they are Scale Hardwear products first used on Martins A4 ....I had a few left over

Regards

Bob

An alternative would be to attach the reversing rod to the chassis rather than the running plate but depending on the valve gear setting the reversing rod fore and aft movement would require a degree of access through the running plate and into the lower firebox area. That I imagine could be problematic when it comes to marrying the body to the chassis

Re the Slide Bar bolt head detail, yes they are Scale Hardwear products first used on Martins A4 ....I had a few left over

Regards

Bob

Last edited:

P A D

Western Thunderer

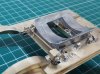

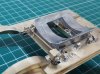

After a lull in proceedings I have now completed the valve gear and all runs smoothly.

The front and rear valve rods have been linked with a short lengh of suitable tube, and the 2:1 levers are working fine despite the 90 degree cranks.

I have also added some M0 hex nuts to represent the fixing on the slide bars. These were sourced from prime miniatures.

All that remains is the addition of some 1mm square brass at the end of the slide bars to close the gap.

Cheers,

Peter

The front and rear valve rods have been linked with a short lengh of suitable tube, and the 2:1 levers are working fine despite the 90 degree cranks.

I have also added some M0 hex nuts to represent the fixing on the slide bars. These were sourced from prime miniatures.

All that remains is the addition of some 1mm square brass at the end of the slide bars to close the gap.

Cheers,

Peter

P A D

Western Thunderer

Here's a shot showing the length of halved tubing slotted over the front and rear valve rods to connect them.

The cylinder wrappers are now soldered in place.

And the other side showing the reversing rod is also attached.

The rod just sits behind the arm on the lifting link and is not connected. That way when the gear is altered the arm moves behind the rod.

The end of the rod is mostly hidden behind the valance, so it is hardly noticeable that it extends beyond the arm when in reverse.

At the rear end I have cut the rod just inside the slot in the fire box so it should be possible to slide it out of the slot when the running plate is removed for painting.

I think I just need to add a length of 1 x 1mm square rod and the cylinder drain cocks to complete the chassis. That is, apart from the pick ups and motor. I can then start adding the remaining details to the body.

Cheers,

Peter

The cylinder wrappers are now soldered in place.

And the other side showing the reversing rod is also attached.

The rod just sits behind the arm on the lifting link and is not connected. That way when the gear is altered the arm moves behind the rod.

The end of the rod is mostly hidden behind the valance, so it is hardly noticeable that it extends beyond the arm when in reverse.

At the rear end I have cut the rod just inside the slot in the fire box so it should be possible to slide it out of the slot when the running plate is removed for painting.

I think I just need to add a length of 1 x 1mm square rod and the cylinder drain cocks to complete the chassis. That is, apart from the pick ups and motor. I can then start adding the remaining details to the body.

Cheers,

Peter

P A D

Western Thunderer

As I had the cylinders off to add the drain cocks I took a shot from inside showing the open side of the tube joining the valve rods.

Drain cocks and pipes added.

And a view from above of the completed cylinders and valve gear.

As Richard Lambert did on his A3 build, I have added a looped bracket around the front sand pipe, and attached it to the rear bogie splasher. A representaton of the fixing brackets for front bogie splasher were also added from waste etch.

And the completed chassis excluding motor and pick ups.

I also need to added the Ragstone injectors inside the rear frames. I'm not sure how they were mounted, but I assume they would be similar to the A4.

Here's a view of the cylinders and drain cocks. This also shows that the gap at the end of the slide bars has now been closed.

Moving back to the body, I modified the smoke box door casting to make it removable. I filed a couple of slots in the smoke box ring and added a bracket to the rear of the door to make a sort of bayonet fitting. I need to add some rolled up lead sheet to the boiler and this is just so I can do it later. I suppose for those who like to add sound chips and speakers it would be a useful way of getting the necessary gubbins in an out.

Here it is back in place.

And from the other side. Starting to look good now it's got its face on.

It is now substantially complete, but there is still a myriad of castings to add, along with lots of copper piping and of the course the back head.

Cheers,

Peter

Drain cocks and pipes added.

And a view from above of the completed cylinders and valve gear.

As Richard Lambert did on his A3 build, I have added a looped bracket around the front sand pipe, and attached it to the rear bogie splasher. A representaton of the fixing brackets for front bogie splasher were also added from waste etch.

And the completed chassis excluding motor and pick ups.

I also need to added the Ragstone injectors inside the rear frames. I'm not sure how they were mounted, but I assume they would be similar to the A4.

Here's a view of the cylinders and drain cocks. This also shows that the gap at the end of the slide bars has now been closed.

Moving back to the body, I modified the smoke box door casting to make it removable. I filed a couple of slots in the smoke box ring and added a bracket to the rear of the door to make a sort of bayonet fitting. I need to add some rolled up lead sheet to the boiler and this is just so I can do it later. I suppose for those who like to add sound chips and speakers it would be a useful way of getting the necessary gubbins in an out.

Here it is back in place.

And from the other side. Starting to look good now it's got its face on.

It is now substantially complete, but there is still a myriad of castings to add, along with lots of copper piping and of the course the back head.

Cheers,

Peter

P A D

Western Thunderer

Thanks JB.

I need to be careful or otherwise I may end up adding opening smoke doors and tube plates etc., like some other lunatics on here!

For me it's just a temporary diversion so I can add weight later, but as I said it could be useful for accessing sound chips and other such gubbins in the boiler. It would be better to make the "bayonet" fitting before putting the ring on and then a stop could be added on the inside. Once I put the lead in I'll snip off the brackets so I can accurately line up the door and fix it with epoxy.

Cheers,

Peter

I need to be careful or otherwise I may end up adding opening smoke doors and tube plates etc., like some other lunatics on here!

For me it's just a temporary diversion so I can add weight later, but as I said it could be useful for accessing sound chips and other such gubbins in the boiler. It would be better to make the "bayonet" fitting before putting the ring on and then a stop could be added on the inside. Once I put the lead in I'll snip off the brackets so I can accurately line up the door and fix it with epoxy.

Cheers,

Peter

P A D

Western Thunderer

The top lamp bracket on the door has been added using a spare PRC casting. I drilled the mounting and added a pin of 0.7mm NS rod, then inserted it through the hole and soldered from the inside.

The main handrail and injector pipe are temporarily fitted but not soldered in place. They will be removed for painting and lining then refitted later and glued in place.

The cab end after adding the wash out plugs and mud hole clamps. The short handrail on the fire box side is permanently fixed.

And the other side. I have managed to break the lower mud hole clamps and will re glue it later.

Some A3s had an additional wash out plugs on the sloping front of the fire box and this has been made from scratch.

And the other side.

The right hand super heater cover and snifting valve.

The left hand cover has still to be added

And a couple of gratuitous broadside shots.

The smoke box saddle is now epoxied to the running plate so next up will be the various pipes and unions on the sides of the smoke box.

Here's how it can be broken down for adding the remaining details.

Cheers,

Peter

The main handrail and injector pipe are temporarily fitted but not soldered in place. They will be removed for painting and lining then refitted later and glued in place.

The cab end after adding the wash out plugs and mud hole clamps. The short handrail on the fire box side is permanently fixed.

And the other side. I have managed to break the lower mud hole clamps and will re glue it later.

Some A3s had an additional wash out plugs on the sloping front of the fire box and this has been made from scratch.

And the other side.

The right hand super heater cover and snifting valve.

The left hand cover has still to be added

And a couple of gratuitous broadside shots.

The smoke box saddle is now epoxied to the running plate so next up will be the various pipes and unions on the sides of the smoke box.

Here's how it can be broken down for adding the remaining details.

Cheers,

Peter

Rob Pulham

Western Thunderer

Beautiful Peter!

P A D

Western Thunderer

Looking great. However that'll be the ejector pipe

JB.

Whoops!

Or is it a case of you say ejector I say injector? Nah.

And thanks to you and Rob for the kind words.

Cheers,

Peter

P A D

Western Thunderer

Thanks Mick.

It's been a joy to build and I'm looking forward to doing the A4. However, next up will be the MOK STD 4 tank. It will be good to compare it to the DJB one I build many years ago.

Will you be at Leigh next week? If I can get there I'll bring the A3 and you and Richard can cast a critical eye over it.

Cheers,

Peter

It's been a joy to build and I'm looking forward to doing the A4. However, next up will be the MOK STD 4 tank. It will be good to compare it to the DJB one I build many years ago.

Will you be at Leigh next week? If I can get there I'll bring the A3 and you and Richard can cast a critical eye over it.

Cheers,

Peter

Hope you can get to Leigh next week so we can see your handiwork. You have changed your kit preferences since I first commented on your Duchess build. We both bought the same kit at the same show over the Finney7 one, if only I could devote the same amount of time to get it built

I was also looking at the MOK tank as another one to buy and saw a well built one at the Preston Open day. Will look forward to your build to give us a different view to the S7 write up

I was also looking at the MOK tank as another one to buy and saw a well built one at the Preston Open day. Will look forward to your build to give us a different view to the S7 write up

adrian

Flying Squad

Damn - does that mean we need to organise a flash mob at an alternative location?We won't be at Leigh this year.

P A D

Western Thunderer

Hi Peter,

We won't be at Leigh this year.

Your A3 looks lovely - a super build. You will be able to separate the footplate from the cab. The sanding rod which you haven't yet fitted is more vulnerable than the reverser when dismantling the model.

Richard

Hi Richard,

That's a shame. Maybe at Doncaster??

Thanks for the compliment. I'm wondering if I can add something unobtrusive to the end of the sanding rod, to make it more robust during painting. I've got a Ragstone casting to replace the etched pivot rod so that may help.

Cheers,

Peter

P A D

Western Thunderer

Hope you can get to Leigh next week so we can see your handiwork. You have changed your kit preferences since I first commented on your Duchess build. We both bought the same kit at the same show over the Finney7 one, if only I could devote the same amount of time to get it built

I was also looking at the MOK tank as another one to buy and saw a well built one at the Preston Open day. Will look forward to your build to give us a different view to the S7 write up

Peter,

No, I'll still be in the states until May 3rd I'm afraid, however if I were not, then Leigh is a bit far for an out and back in a day show for me. Next show will be Doncaster, where I believe we met last year with your L1.

Mick D

Hi Parky,

At the time I bought the Duchess, the larger Finney kits were beyond my budget, and I could not justify the extra cost or see the value in it. Having been lucky enough to pick up the A3 at what amounted to a lower price than the Gladiator Duchess, I have now experienced the fidelity and superb fit of the parts of these high end kits. By selling some of my earlier models I have been able to finance the A4 and 80000. No doubt I'll be selling some others at a later date for further purchases from F7.

Mick,

Sorry you won't be at Leigh but I wish you a good holiday. Maybe I'll catch up with you at Doncaster.

Cheers,

Peter

P A D

Western Thunderer

The running plate detail is now complete with the addition of the sand operating levers, lubricators and oil pots.

As Dikitriki mentioned the rear operating lever for the sanding gear is very vulnerable with the fire box removed so extra care is needed when handling. The cast pivot lever from Ragstone makes it a little more robust than the half etch laminate provided in the kit.

The pull rod was fouling the driving wheels with the chassis in, so I have clipped off the areas that cross behind the splashers.

And a view from the other side showing where the rod has been clipped.

And a view of the linkage across the running plate to the right hand sand box.

The sand box lid is still to be fitted.

Some views of the oil boxes. The sand box lid has been added on this side.

And from the front.

And the other side.

The atomiser and associated pipe work on the smoke box. The ends of the pipes have been soldered together and will just run down behind the frames when back on the running plate. Again extra care is needed when handling as they are quite vulerable.

And the other side.

There is still one vacant port on both sides on each atomiser. When I get the steam pipes castings on, the remaining feed pipes will be be added to the atomisers and the other ends slotted into the union at the bottom of the steam pipes.

At the rear end the ash pan operating lever is now fitted.

And all placed back on the chassis.

Cheers,

Peter

As Dikitriki mentioned the rear operating lever for the sanding gear is very vulnerable with the fire box removed so extra care is needed when handling. The cast pivot lever from Ragstone makes it a little more robust than the half etch laminate provided in the kit.

The pull rod was fouling the driving wheels with the chassis in, so I have clipped off the areas that cross behind the splashers.

And a view from the other side showing where the rod has been clipped.

And a view of the linkage across the running plate to the right hand sand box.

The sand box lid is still to be fitted.

Some views of the oil boxes. The sand box lid has been added on this side.

And from the front.

And the other side.

The atomiser and associated pipe work on the smoke box. The ends of the pipes have been soldered together and will just run down behind the frames when back on the running plate. Again extra care is needed when handling as they are quite vulerable.

And the other side.

There is still one vacant port on both sides on each atomiser. When I get the steam pipes castings on, the remaining feed pipes will be be added to the atomisers and the other ends slotted into the union at the bottom of the steam pipes.

At the rear end the ash pan operating lever is now fitted.

And all placed back on the chassis.

Cheers,

Peter