Dikitriki

Flying Squad

Hi,

A bit of an indulgence this, as it's not Heyside related, but what the heck . It's a kit I have had for a number of years, another of my part-started bargain buys from a show. In fact little had been done (front footplate and bogie from memory) but what had, had been done pretty well. It still all got blow-torched apart, but it meant that every part was perfectly useable. I was fortunately able to find all the boxes in the chaotic mess of the room Heyside lives in, as it is just dumped after the Doncaster show.

. It's a kit I have had for a number of years, another of my part-started bargain buys from a show. In fact little had been done (front footplate and bogie from memory) but what had, had been done pretty well. It still all got blow-torched apart, but it meant that every part was perfectly useable. I was fortunately able to find all the boxes in the chaotic mess of the room Heyside lives in, as it is just dumped after the Doncaster show.

The Duchess is one of my favourite locomotives, and I have 3 to do. A de-streamlined from an MMP kit which is slowly going through the paint shops (18 years and counting), this one which is non-streamlined, and a David Andrews kit for one of the last 2. I shall spend tonight going through the boxes and instructions to remind myself where I am up to, and finding all my research sources.

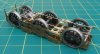

Tomorrow, I shall recommence work on the tender and take some photos of the tender chassis which is pretty far advanced. One thing I have to think about is the compensation.......in that I have made it with compensation, but I'm not convinced it's what I really want to do.

Richard

A bit of an indulgence this, as it's not Heyside related, but what the heck

. It's a kit I have had for a number of years, another of my part-started bargain buys from a show. In fact little had been done (front footplate and bogie from memory) but what had, had been done pretty well. It still all got blow-torched apart, but it meant that every part was perfectly useable. I was fortunately able to find all the boxes in the chaotic mess of the room Heyside lives in, as it is just dumped after the Doncaster show.

. It's a kit I have had for a number of years, another of my part-started bargain buys from a show. In fact little had been done (front footplate and bogie from memory) but what had, had been done pretty well. It still all got blow-torched apart, but it meant that every part was perfectly useable. I was fortunately able to find all the boxes in the chaotic mess of the room Heyside lives in, as it is just dumped after the Doncaster show.The Duchess is one of my favourite locomotives, and I have 3 to do. A de-streamlined from an MMP kit which is slowly going through the paint shops (18 years and counting), this one which is non-streamlined, and a David Andrews kit for one of the last 2. I shall spend tonight going through the boxes and instructions to remind myself where I am up to, and finding all my research sources.

Tomorrow, I shall recommence work on the tender and take some photos of the tender chassis which is pretty far advanced. One thing I have to think about is the compensation.......in that I have made it with compensation, but I'm not convinced it's what I really want to do.

Richard

, equalising beams / compensation, whilst effective and overall easy to set up, are so 'Roman engineering' a Stanier engine requires a more elegant approach I feel

, equalising beams / compensation, whilst effective and overall easy to set up, are so 'Roman engineering' a Stanier engine requires a more elegant approach I feel