I've been threatening, promising to do this for some time, and so the time has come.

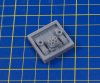

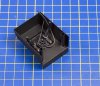

A light blocking smoke box interior and blast pipe, the huge gaping chimney leaves a big hole through which you can see the track and at some angles the slide bars and connecting rods.

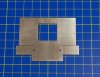

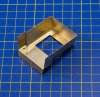

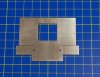

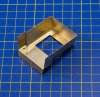

It's a simple fold up affair, compromised slightly by the thickness of the resin sides, but none the less does what it says on the tin.

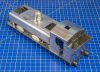

The casting for the middle cylinder top sits in a recess, from my research so far, there are two types, those with a flat rim around the sloping top to the casting (as modeled here) and those with a sloping rim that follows the slope in the casting. The latter would require a different smokebox floor that also slopes and not the easy simple flat one we have here.

Which engines have which or when they were changed and from which type to which, I have no idea. The Brighton drawings I've seen show a flat floor, some preserved engines have a sloped floor.

I've only modeled up to the mid way point, that's as far as you can see peering down the chimney. I do want to make at least one model with an open smoke box door, but that will require a whole new etched front end overlay and cutting back of the resin casting. When I do that I'll develop the smoke box interior above half way.

It's quite simple in there, no idea what the pipe coming out the front of the blast pipe casting is for, but the blower ring is obvious as are the two live steam 4" pipes to the middle cylinder. Up front are the 7" live steam supplies to the outside cylinders, they should be corrugated and I'll develop a casting as such for the full smoke box package later, as such you only see the merest sliver of the base of the pipes in this set up.

On the real engines, most of the recessed area is filled with concrete to protect the casting from the corrosive ash/moisture/heat, I've not filled mine yet, it seems such a shame to loose most of that detail. Simulating the sloppy concrete daubed by hand, whilst retaining some detail will be a chore; I'll need to work on some sort of resin or sloppy filler that can be sort of poured in there really.

The view originally allowed a direct view down to the tracks or outside motion.

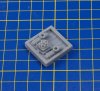

I was pleasantly happy at how much of the new interior was visible once installed, it's hard to photograph and get light in there, but even when you don't shine a light in there it is still readily visible. It'll be a little harder once it's painted, but some light weathering and highlights should show some detail.

Failing all that, it's a complicated way to not see the track any more