David Boorman

Active Member

Mick, thank you for your thoughtful analysis of your experience. I used to blame myself for everything that went wrong with certain kits.

David, well that boiler was straighter than mineWell that's a stunning recovery: excellent work as usual.

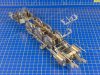

It made me think about the DA A3 I built. I remembered the crappy boiler rolling:

View attachment 118617

but I didn't recall any issues with the firebox being too small. I have checked back and of course I don't have a suitable photo, this being the

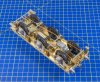

nearest:

View attachment 118619

It doesn't appear to suffer the same malnutrition that the A2 box does.

I now know (in the wallet) how some of David's otherwise excellent designs are let down in the firebox department, as evinced by PAD's wonderful Duchess build. I wonder if he took measurements from the GA and forgot about the clothing...........

Keep up the good work!

David

Tim, you are of course rightProblem is that it is an A3, Mick, so should have a lower cab and ventilator. It might yet get modified, but it it is probably a bit too narrow on the firebox as well and the dome is incorrect for the livery.

Tim

, I missed the bleedin obvious long travel valve covers and dome/viz livery, to focused on the cab

, I missed the bleedin obvious long travel valve covers and dome/viz livery, to focused on the cab  which on closer inspection does appear to have the lower LNER profile ventilator, but clearly also has the GNR higher profile roof....re my point above.

which on closer inspection does appear to have the lower LNER profile ventilator, but clearly also has the GNR higher profile roof....re my point above. So, a couple of holes and a dint in the crinoline to fill first thing tomorrow.

So, a couple of holes and a dint in the crinoline to fill first thing tomorrow.

I'll procure two more tomorrow and fit after paint, they solder nicely to the spring hanger castings so come off when the springs come off to get the wheels out. A quick in and out with a hot iron and a dab of paint and it'll be over quicker than it took to write.

I'll procure two more tomorrow and fit after paint, they solder nicely to the spring hanger castings so come off when the springs come off to get the wheels out. A quick in and out with a hot iron and a dab of paint and it'll be over quicker than it took to write.

its going to be 534 Irish Elegance hence the detail differences I smoke box door fittings and lhs firebox pipeworkHi Mick,

Another stunner, despite all the woes, and firebox re-build, Can't see it anywhere, what's the identity going to be.

Cheers,

Gary

Richard, it's 0.8 mm copper wire and the clips at thin strips of 5 thou simply wrapped around it like real clips and soldered on.I like the neat detail of the AWS conduit that runs along the footplate valence on the lhs. How did you form the tiny cleats?

The client has chosen BR green early 60s, hence the AWS fittings.Beautiful model that fully captures the well-balanced lines of the Peppercorn A1. There was nothing so classy on the London Midland and so I rode over to Leeds and sometimes York just to see these fine engines in 1961. Which livery have you chosen?

) and my 47XX kit is not complete anyway at the moment as those chaps from Finney7 have nicked some bits....... In fact my tender is now on Simon's "Hall" and I picked up a new one at Kettering on Saturday.

) and my 47XX kit is not complete anyway at the moment as those chaps from Finney7 have nicked some bits....... In fact my tender is now on Simon's "Hall" and I picked up a new one at Kettering on Saturday.

, flash between the spring and axle box top required quite a bit of hacking and several springs broke off.

, flash between the spring and axle box top required quite a bit of hacking and several springs broke off.

sprayed the wheels in etch primer