So, continuing with the valve gear, the expansion link requires two holes to be drilled in the castings before assembly. This is not mentioned in the instructions, but phographic evidence and the Beattie drawing shows them to be there. I marked the position for drilling the holes using the drawing as a guide.

And after fitting to the radius rod. This needs to slide freely in the expansion link so ensure there are no burrs left from drilling the holes . Below are the valve rod and slide bars. The upper bars are tabbed together and the tabs removed with the piercing saw after fitting.

Here's the valve rod guide after assembly with the slide bar and rod inserted.

Next, the expansion link brackets ready for fitting to the slide bar bracket.

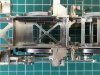

And after fitting with the expansion link and radius rod. Also an upper view of the valve rod guide slide bars, showing the read cast holes for the oil pipe.

Here the eccentric rod has been joined to the expansion link with 0.8 mm NS rod, and to the return crank with the cast pivot supplied. It has been soldered at rear and then dressed flush. Below is the cast brass bearing cover.

And after fitting the cover. This has three lugs which locate in the holes in the bearing face of the return crank. I soldered it with the minimum of solder at these three location only, to avoid the risk of excess solder seeping inside and impairing the rotation.

Here is the cross head and piston after soldering, along with the connecting rod, brass bearing, 12 BA screw and castellated 12 BA nut. Again, this latter hand made item is far from perfect, but will pass muster from normal viewing distances. I'm surprised that MOK don't supply castings for these items, which I'm sure with their pattern making capabilities would be far better than I could make. In this view I have also added the "cork" to the little end of the connecting rod. The rod was cut shorter after this shot was taken.

The system won't let me add the remaining images I wanted to use, despite being below the maximum 15, so I will continue separately.

Cheers,

Peter