SteadyRed

Western Thunderer

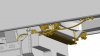

I saw the cab at Doncaster and it certainly looks like this will be the kit to go with, certainly body wise, for shape and ease of build. But I think the MMP underframe might still just have the edge for fidelity but that's simply down to the medium being used. I've not seen the JLTRT underframe in the flesh but I reckon it won't take much to fine detail it.

I'm certainly planning to pick one up at Telford, early BR(E) Finsbury Park engine, D1500-1510 or LMR Crewe based (sans Sereck radiator shutters). I've got an MMP shelf queen class 57 and might transpose parts of the bogies from that, or certainly investigate swapping parts over. Most diesels I can gloss over minutia, but class 40, 47 and Deltics, afraid not

Mick D

Mick

I also saw the Brush 4 cab at Donny, do you know if it was cast in the resin which is used for the kit, as it was quit heavy, I thought that may have been an engineering sample produced just to show what the cab will look like.

Ive not got an JLTRT products, but items from other manufacturers which are resin cast seem much lighter in weight

When I visit the JLTRT stand it was too busy to ask.

Dave