Nick Dunhill

Western Thunderer

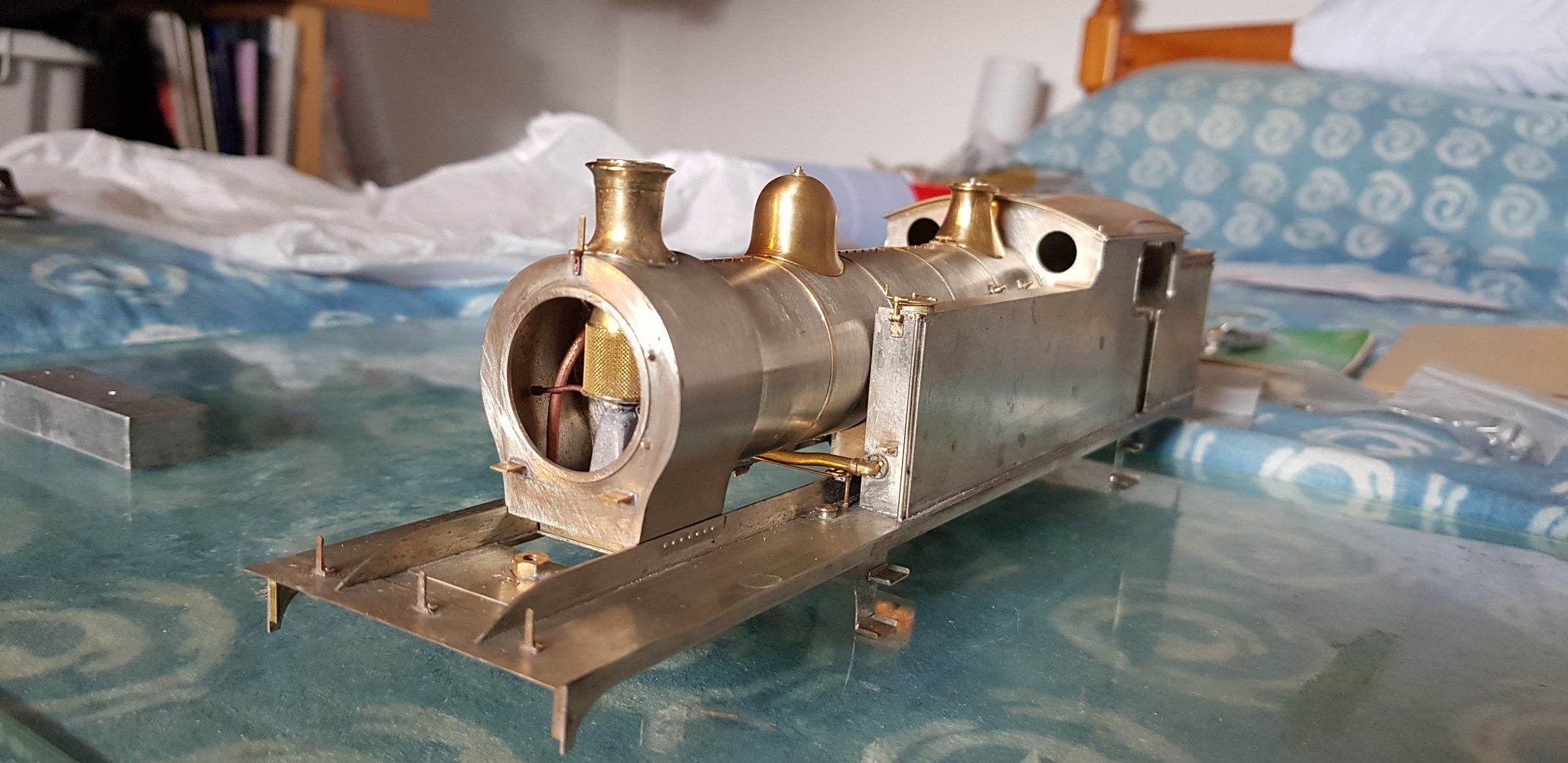

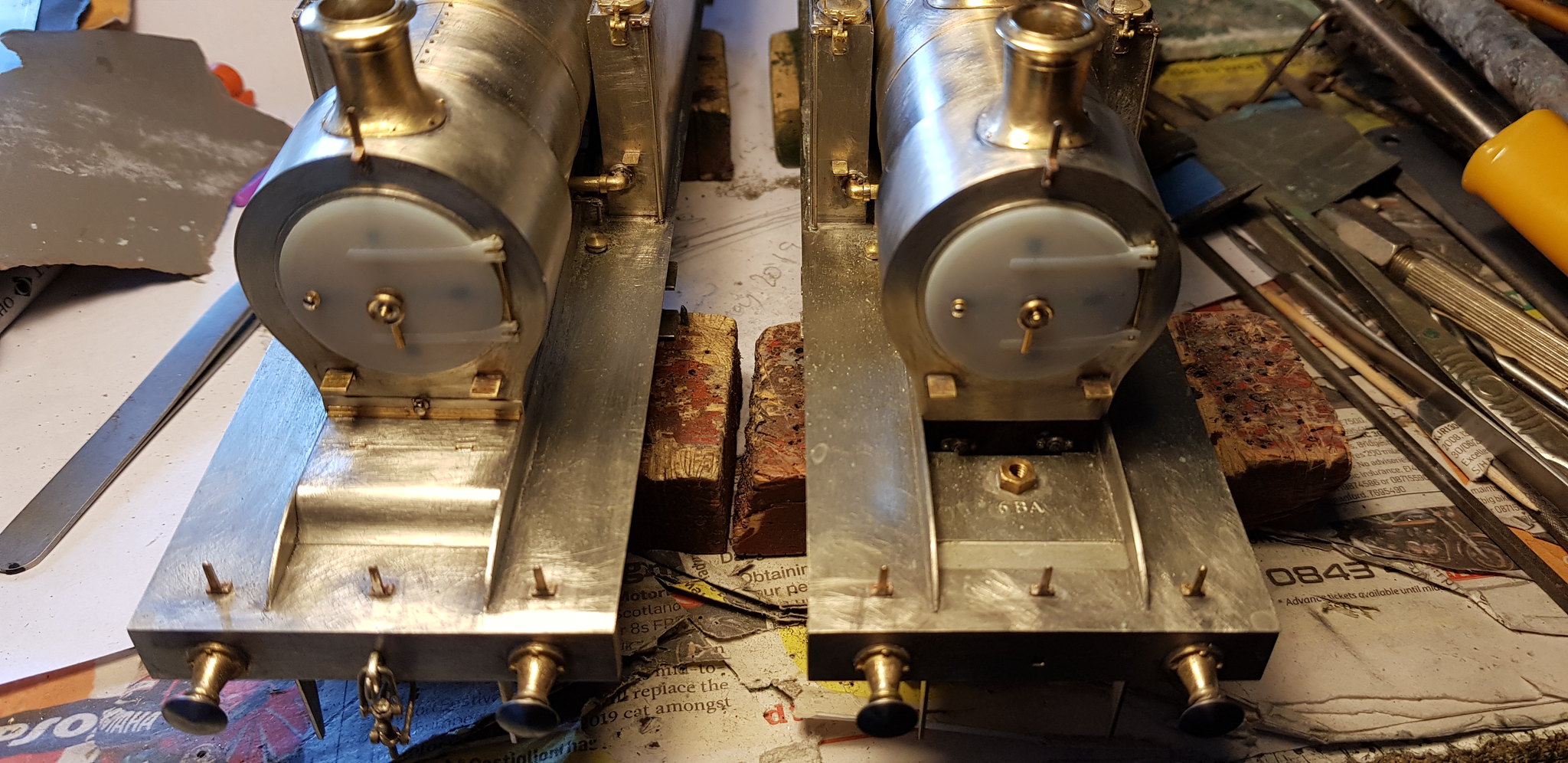

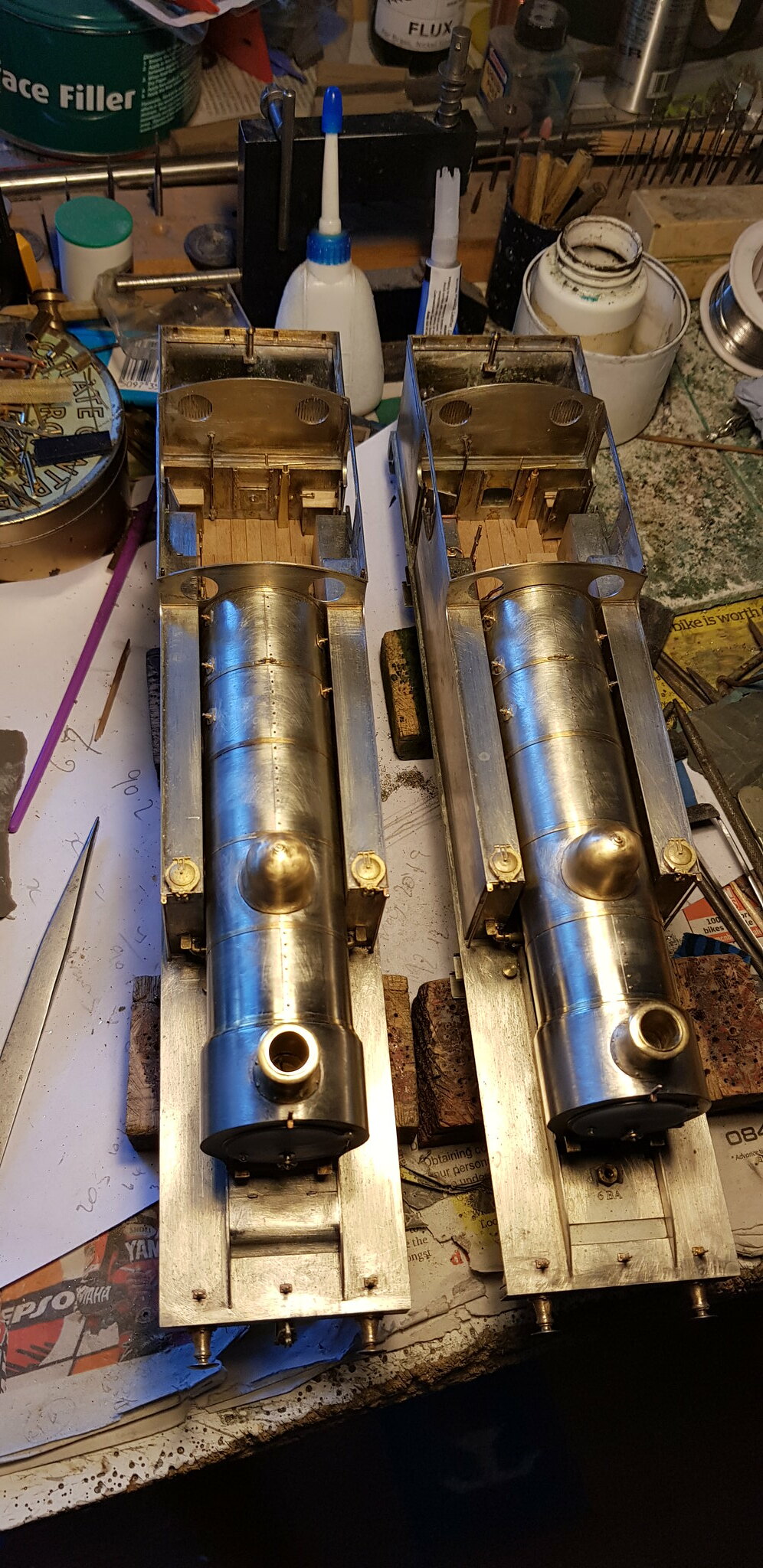

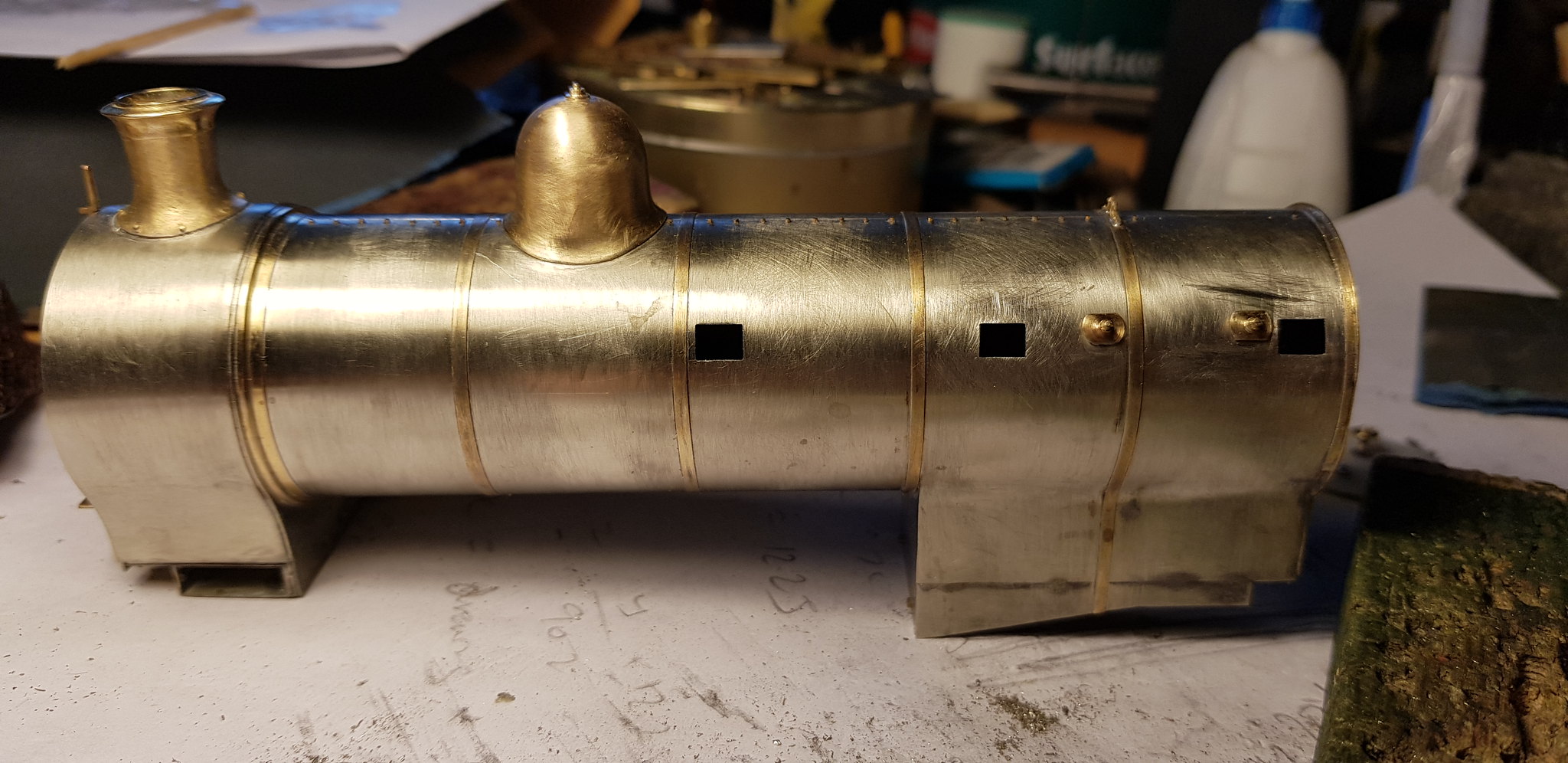

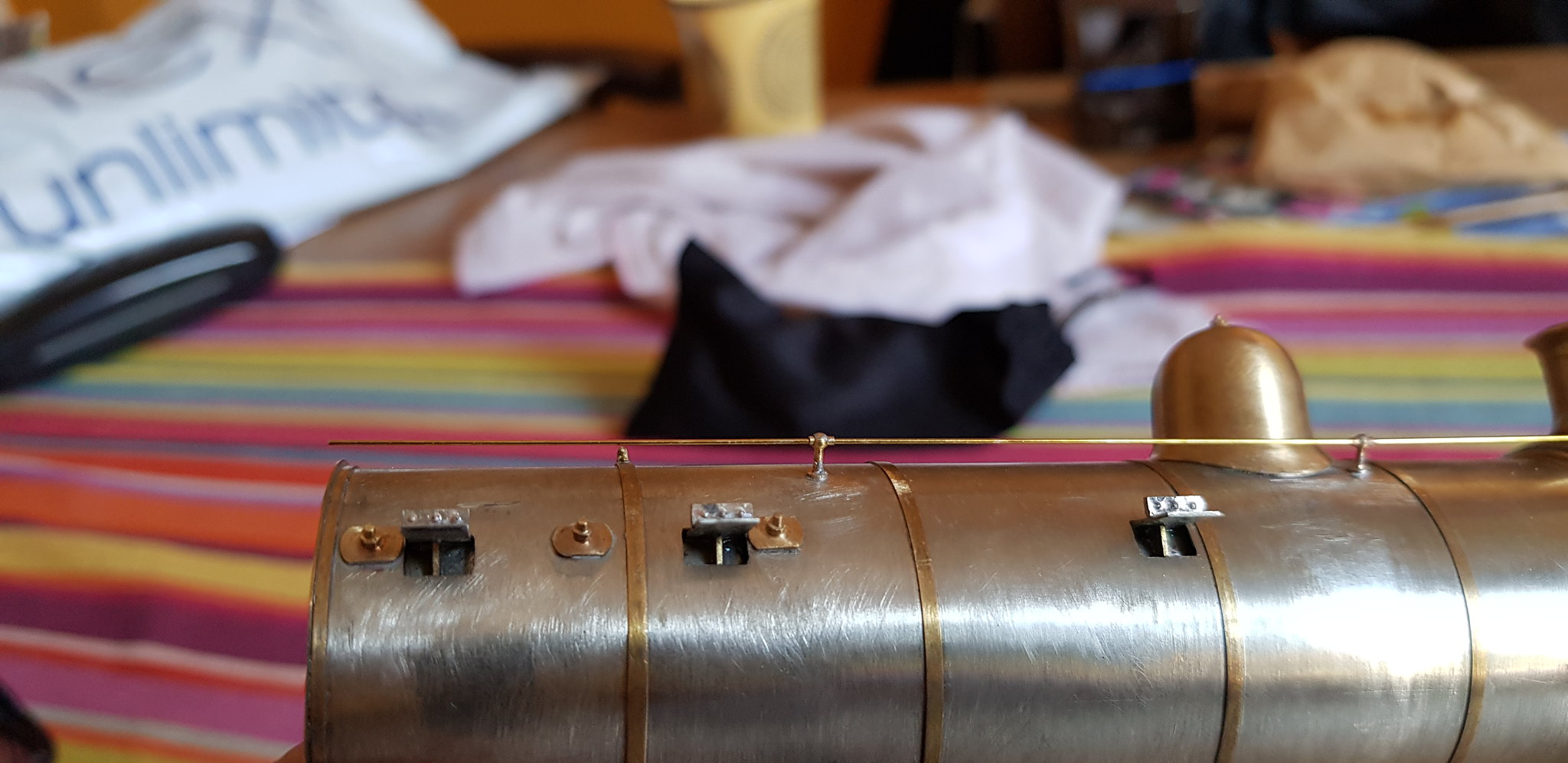

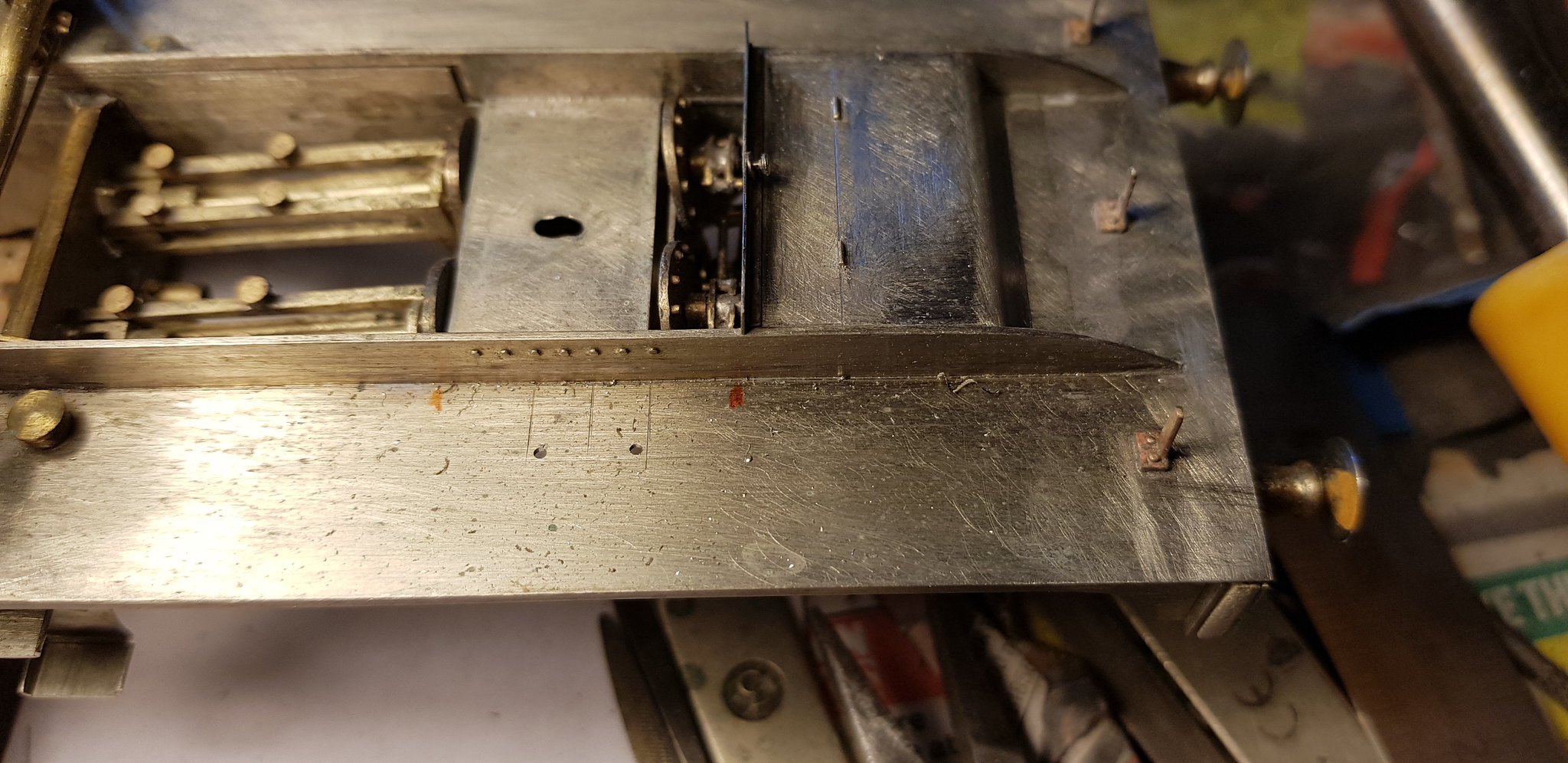

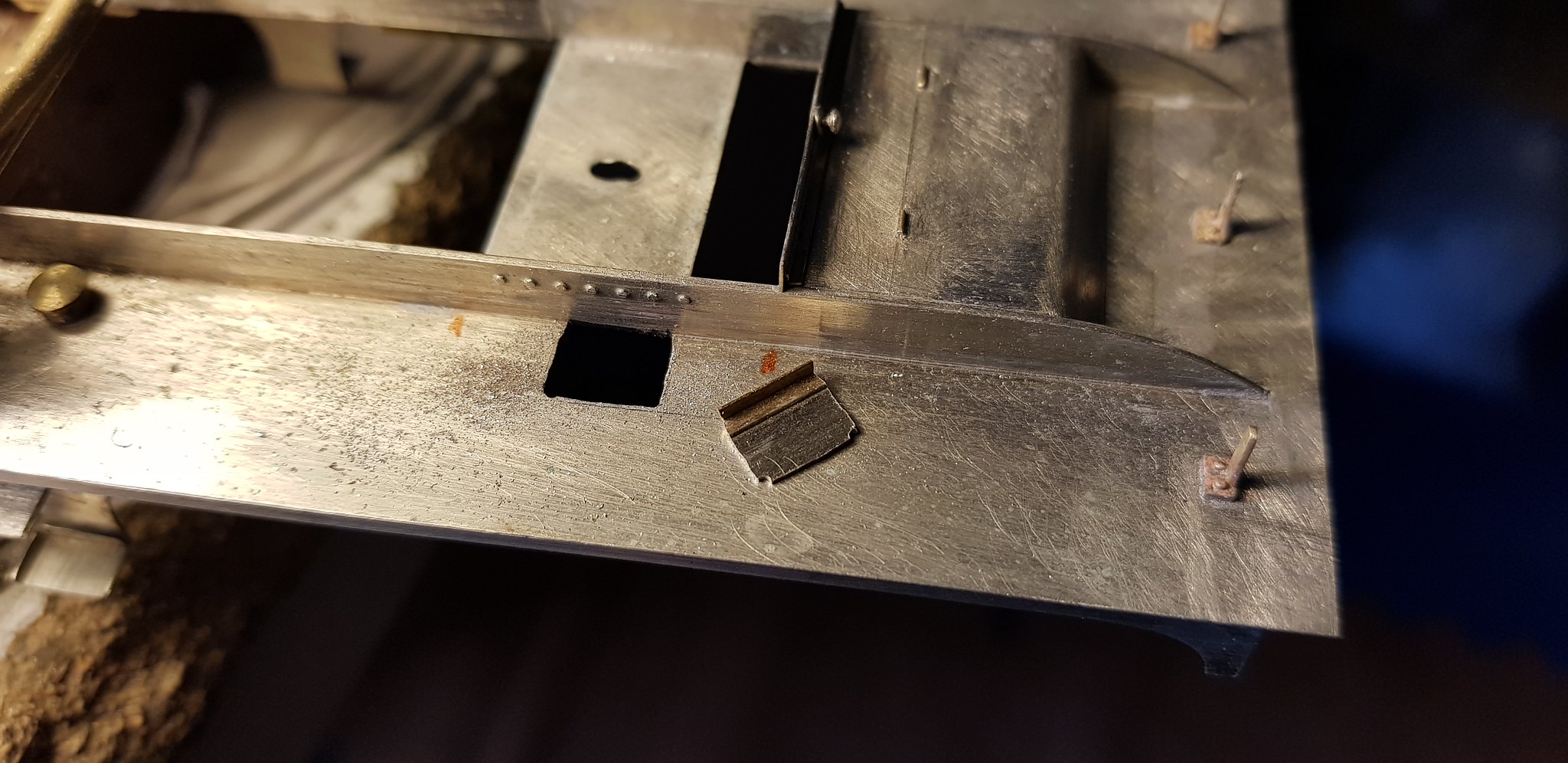

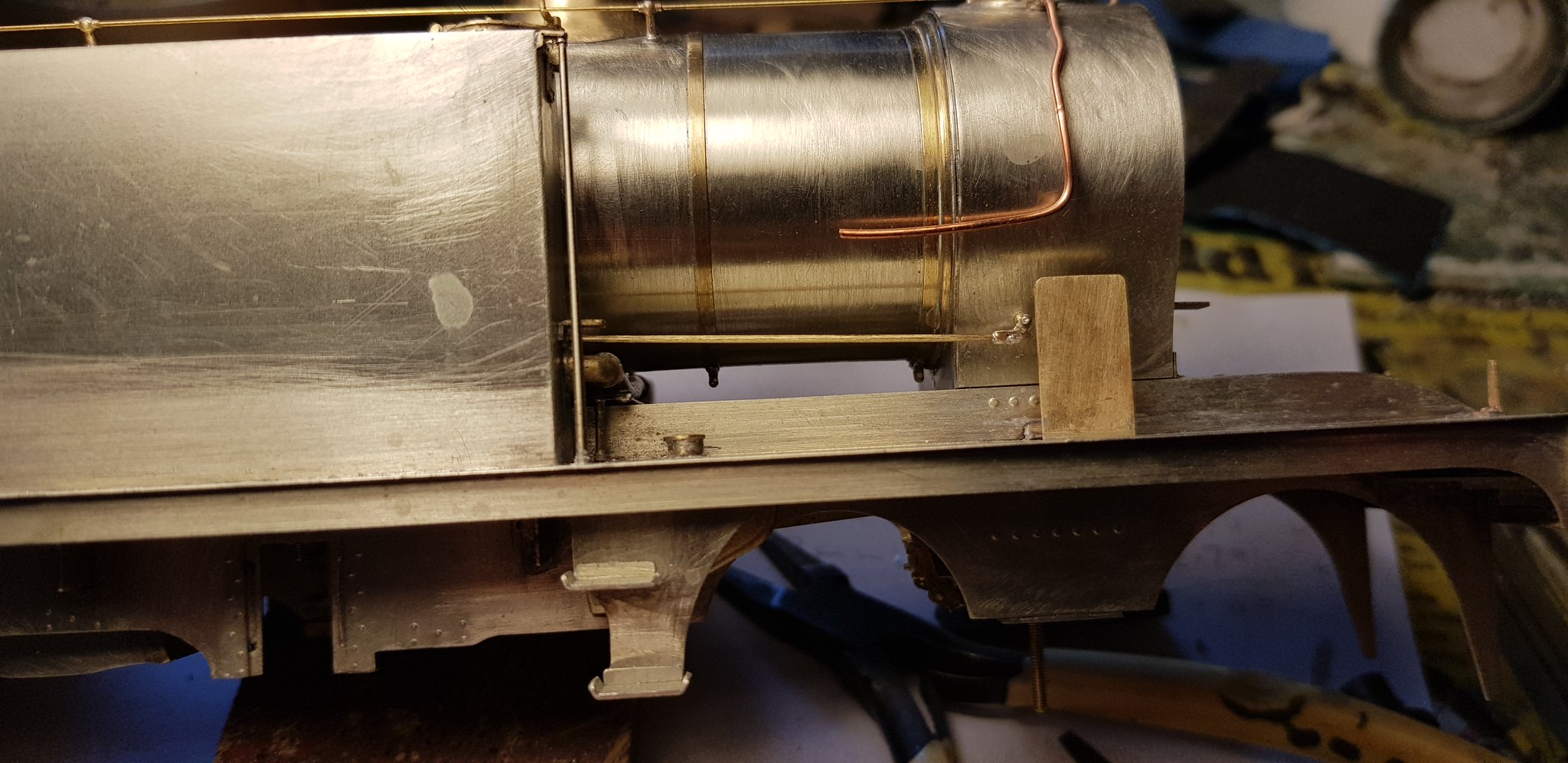

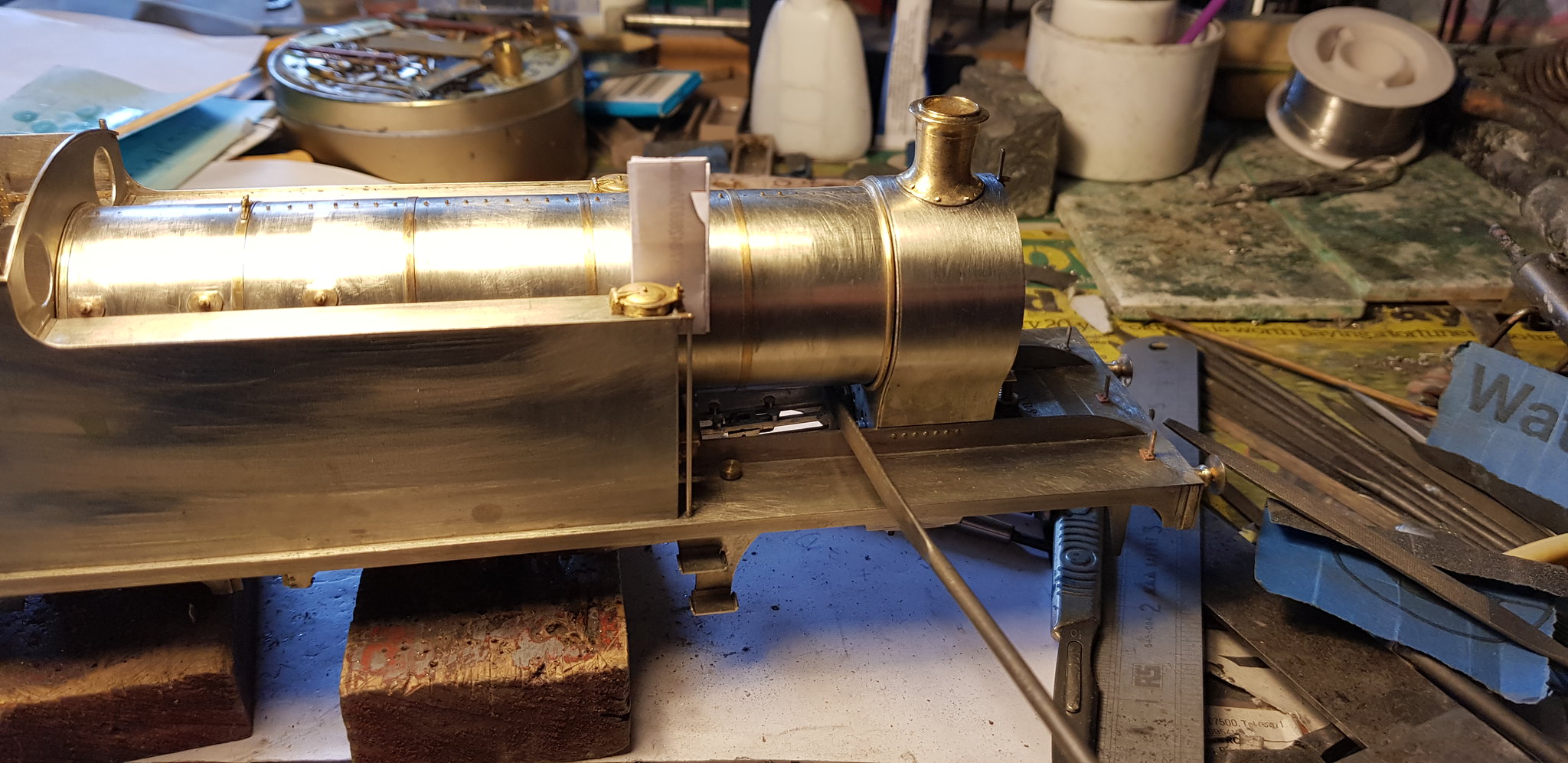

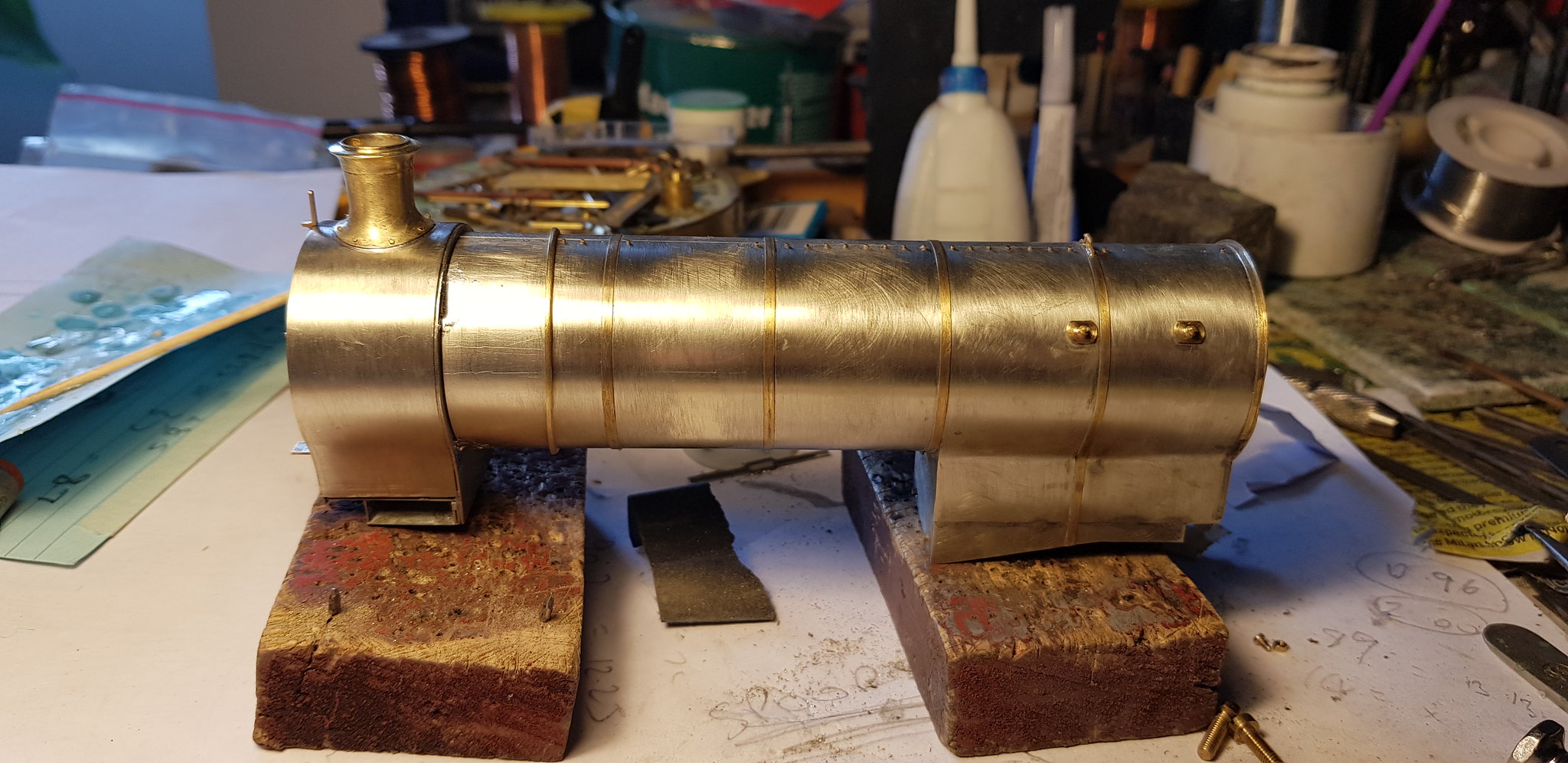

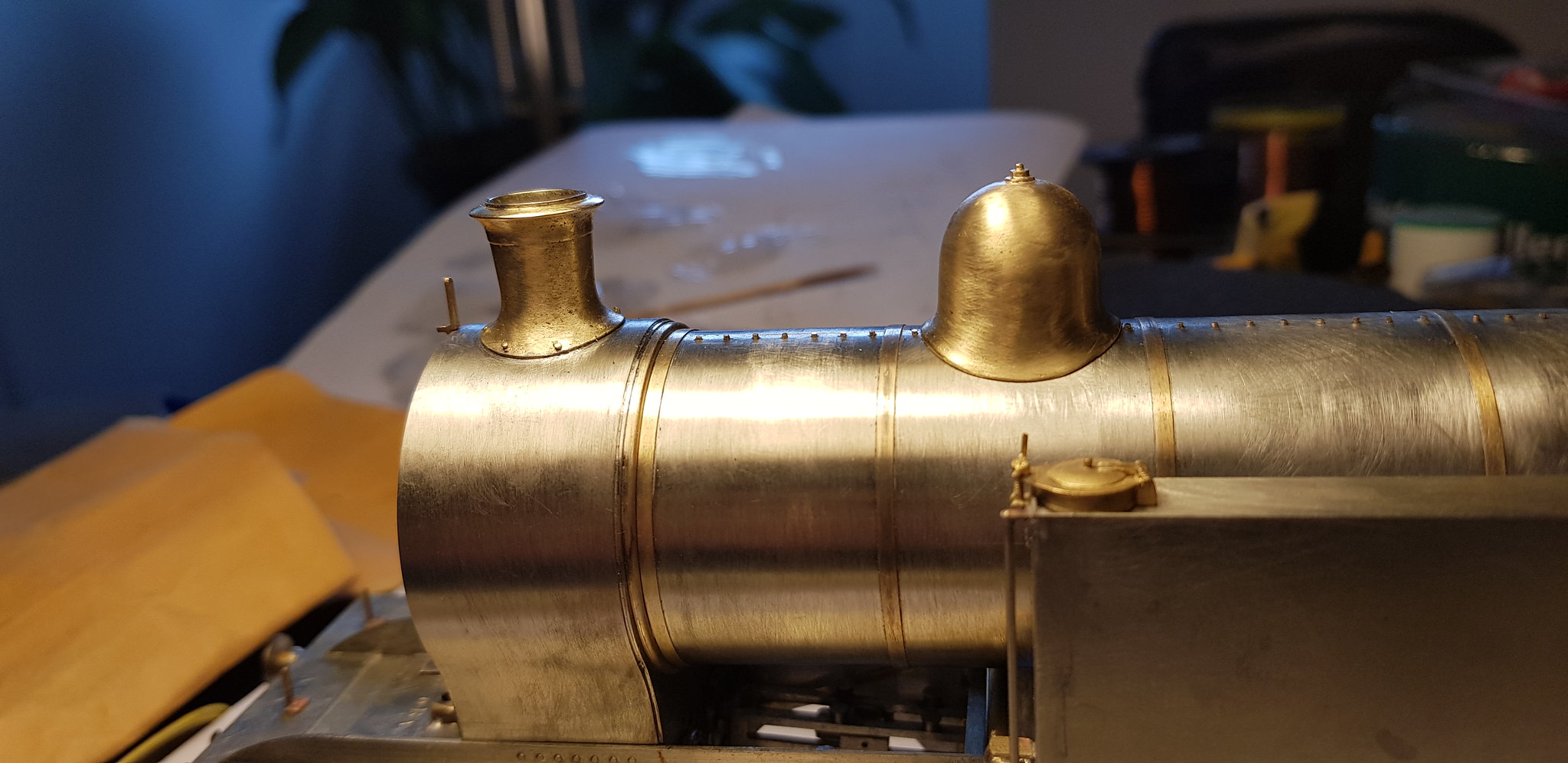

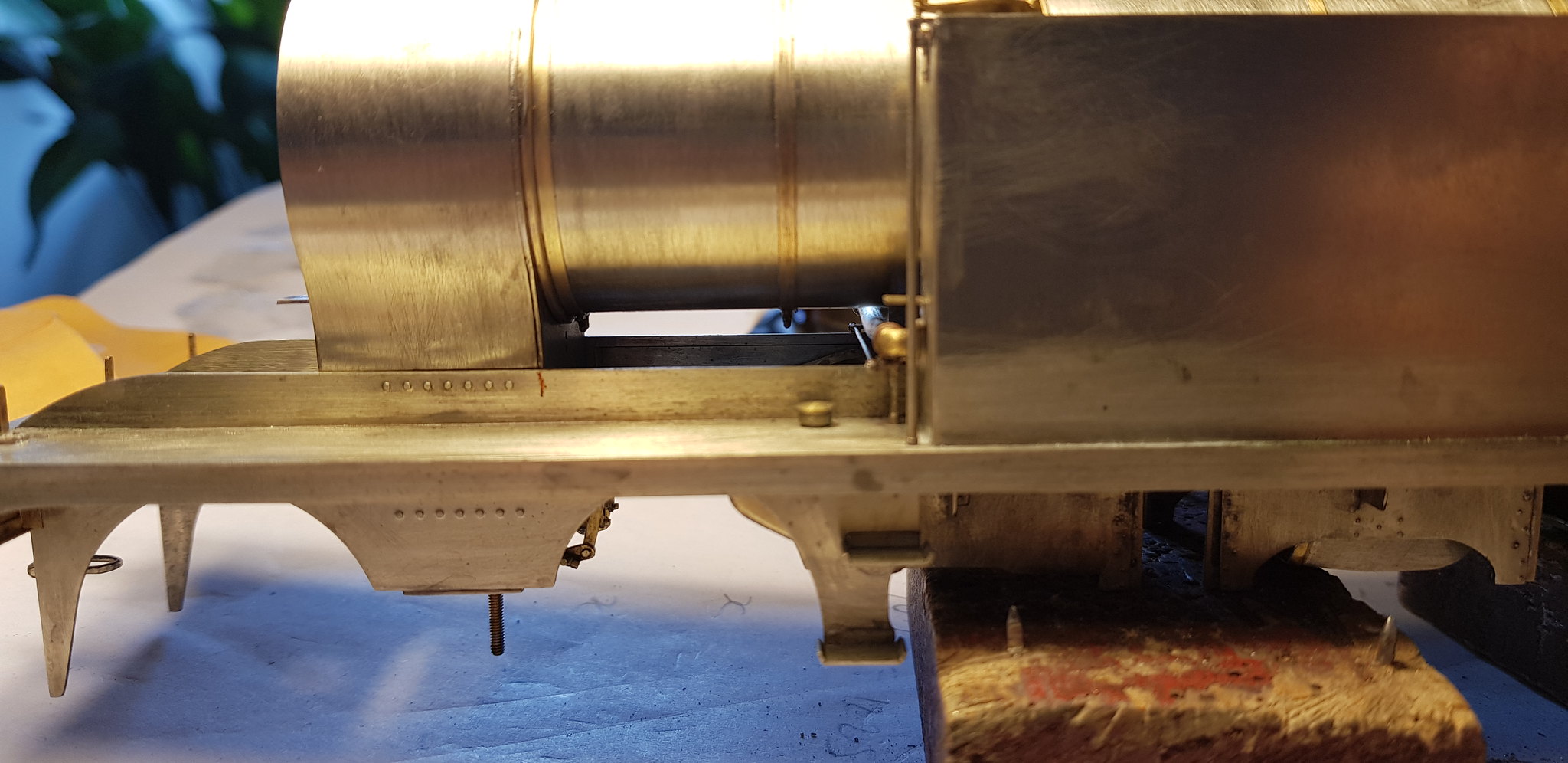

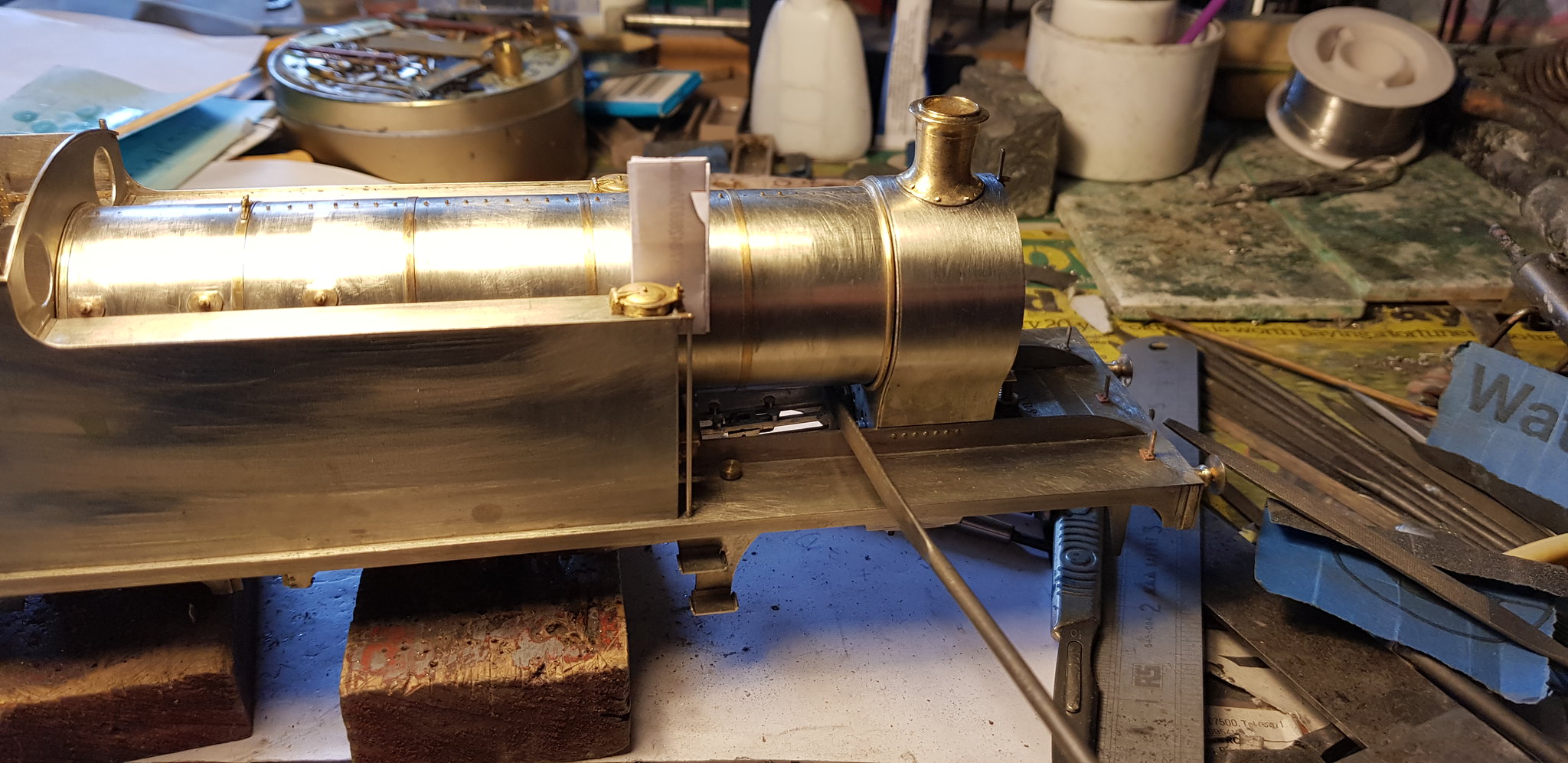

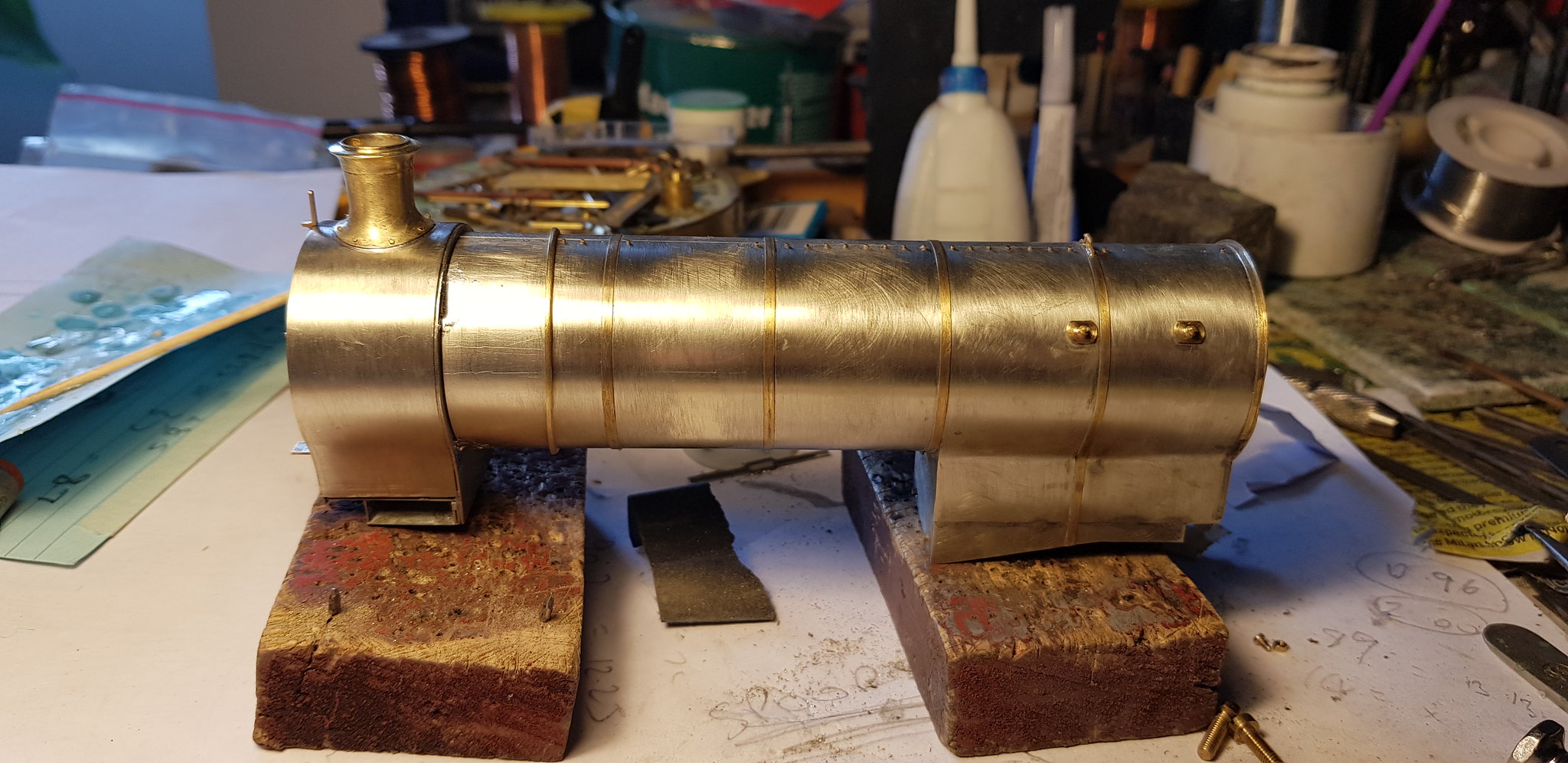

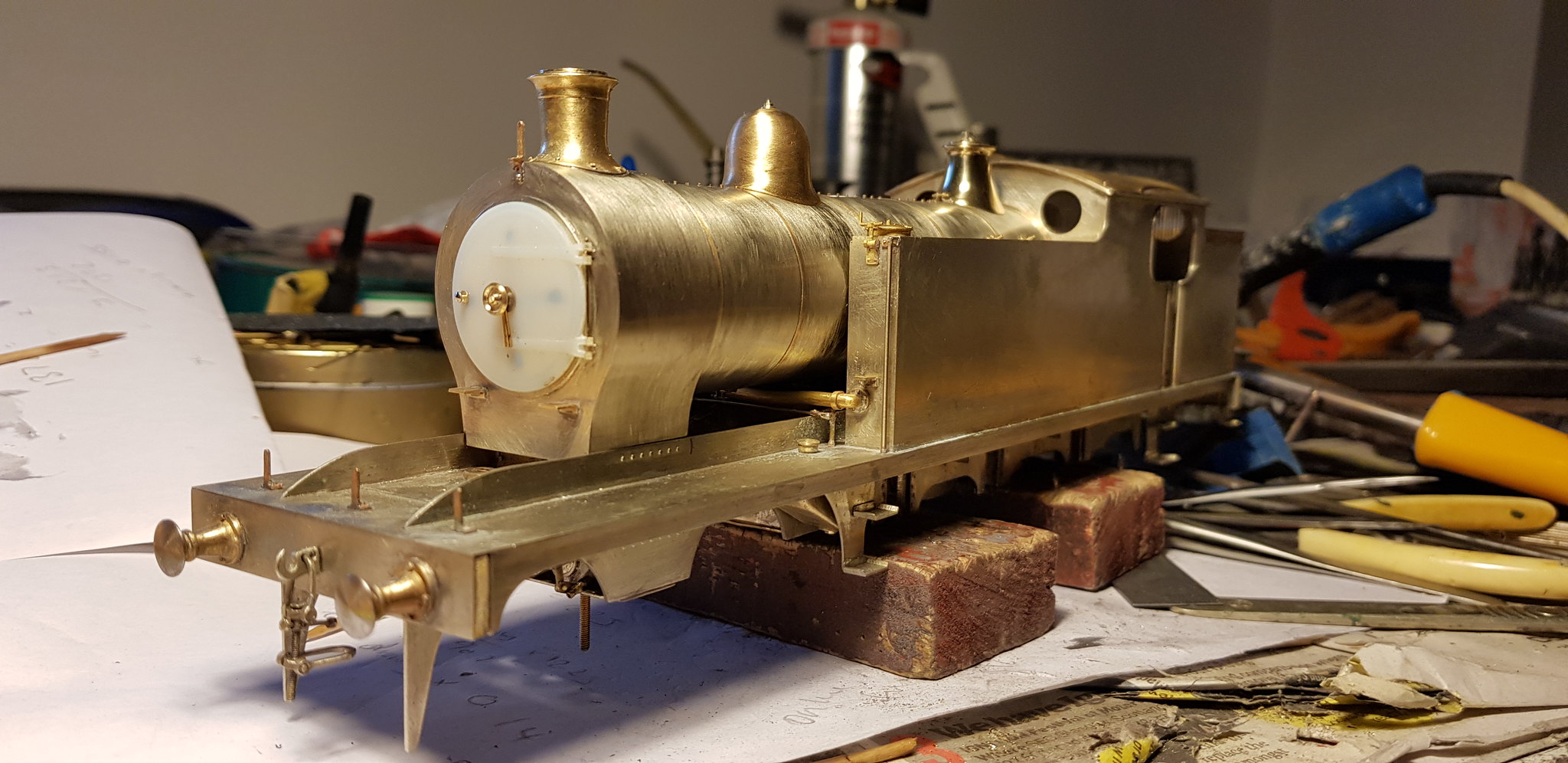

......I have attached one of the smokeboxes to it's loco. I lined up the boiler and smokebox using paper wedges and a tapered file and to get the right alignment then tacked the two together.

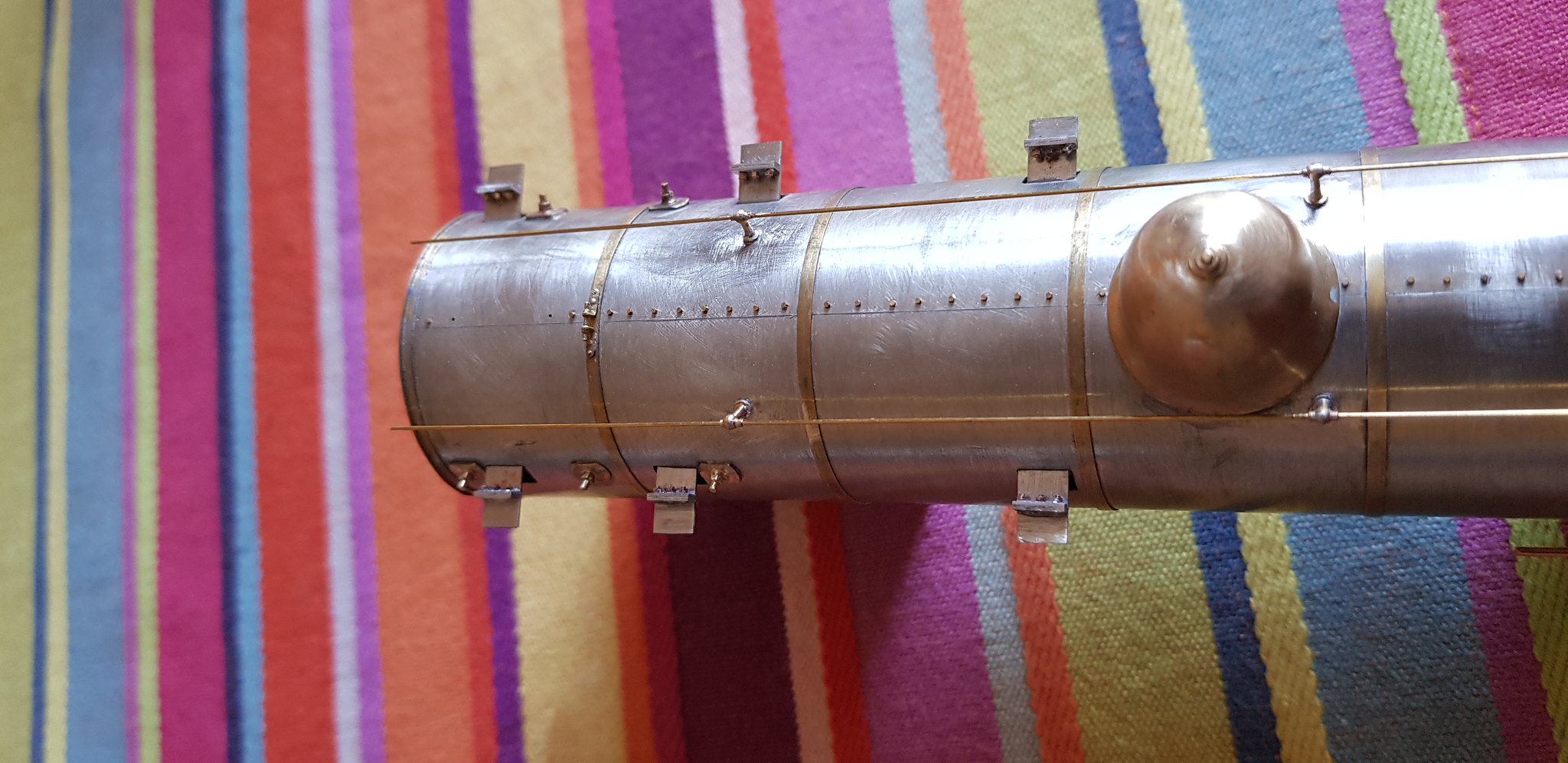

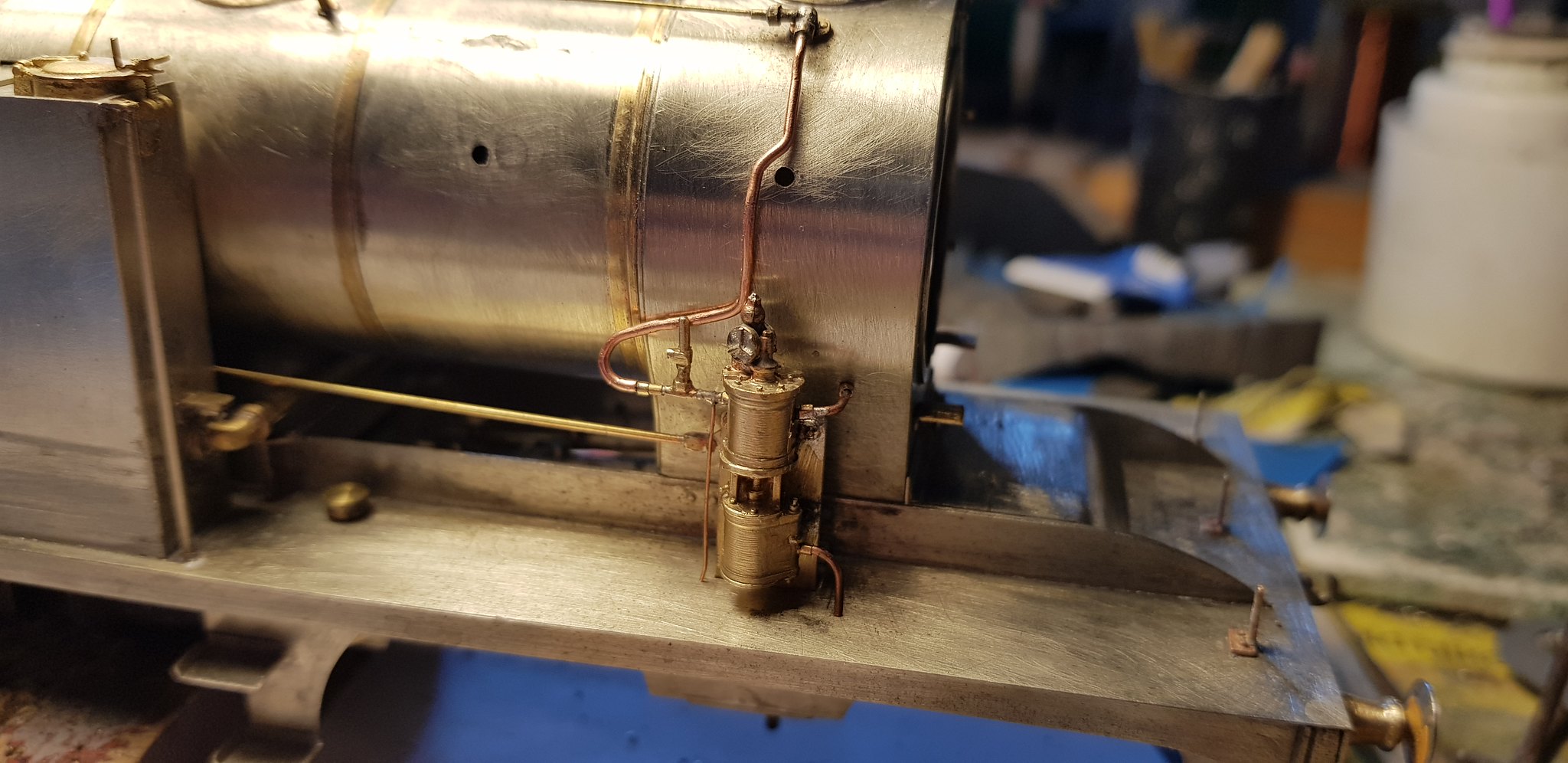

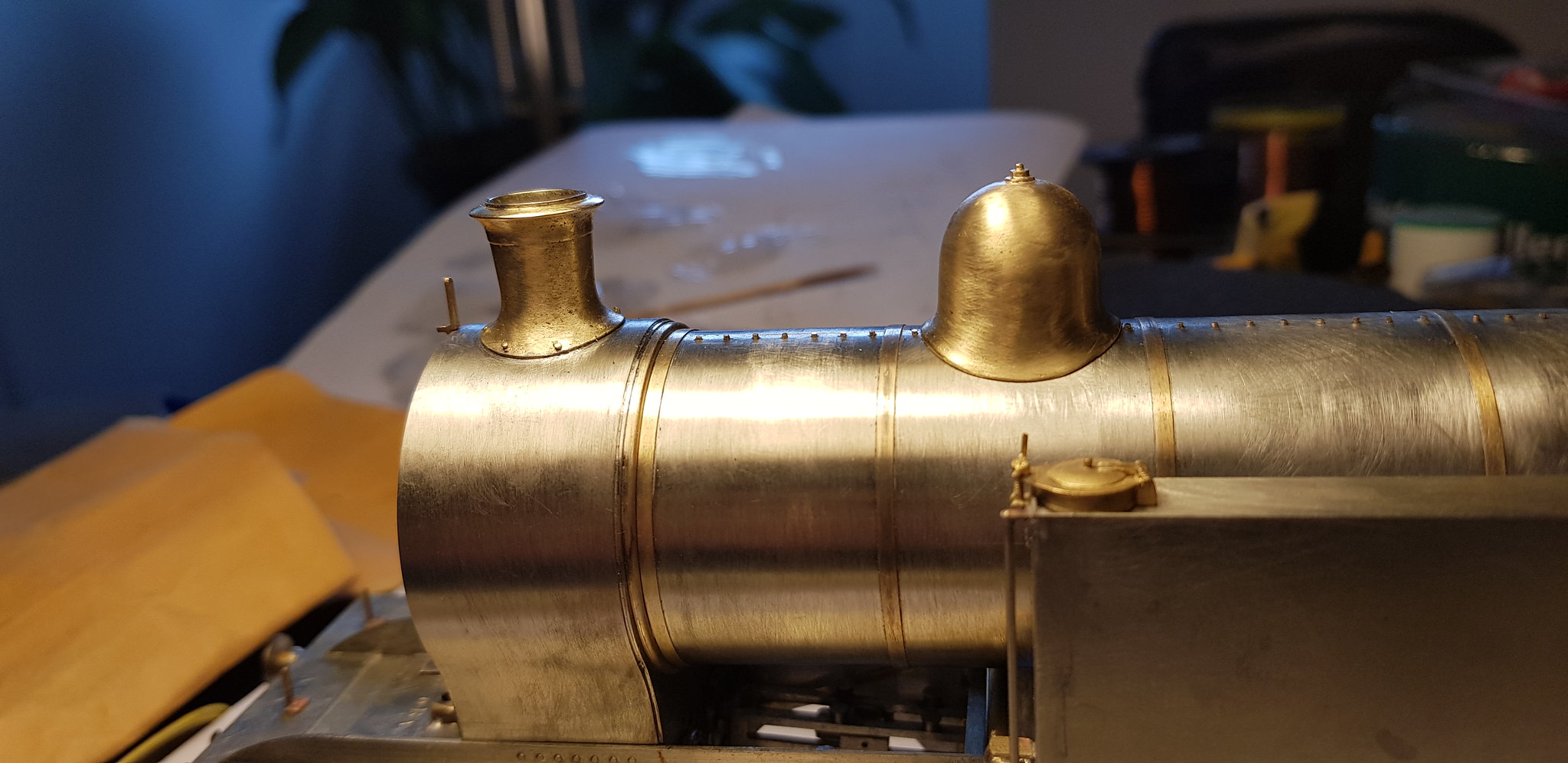

Then the rest of the soldering could be done with the assembly off the rest of the body. I added the polished brass joint cover, the first boiler band, a cleat and the last few screws along the top of the boiler clothing.

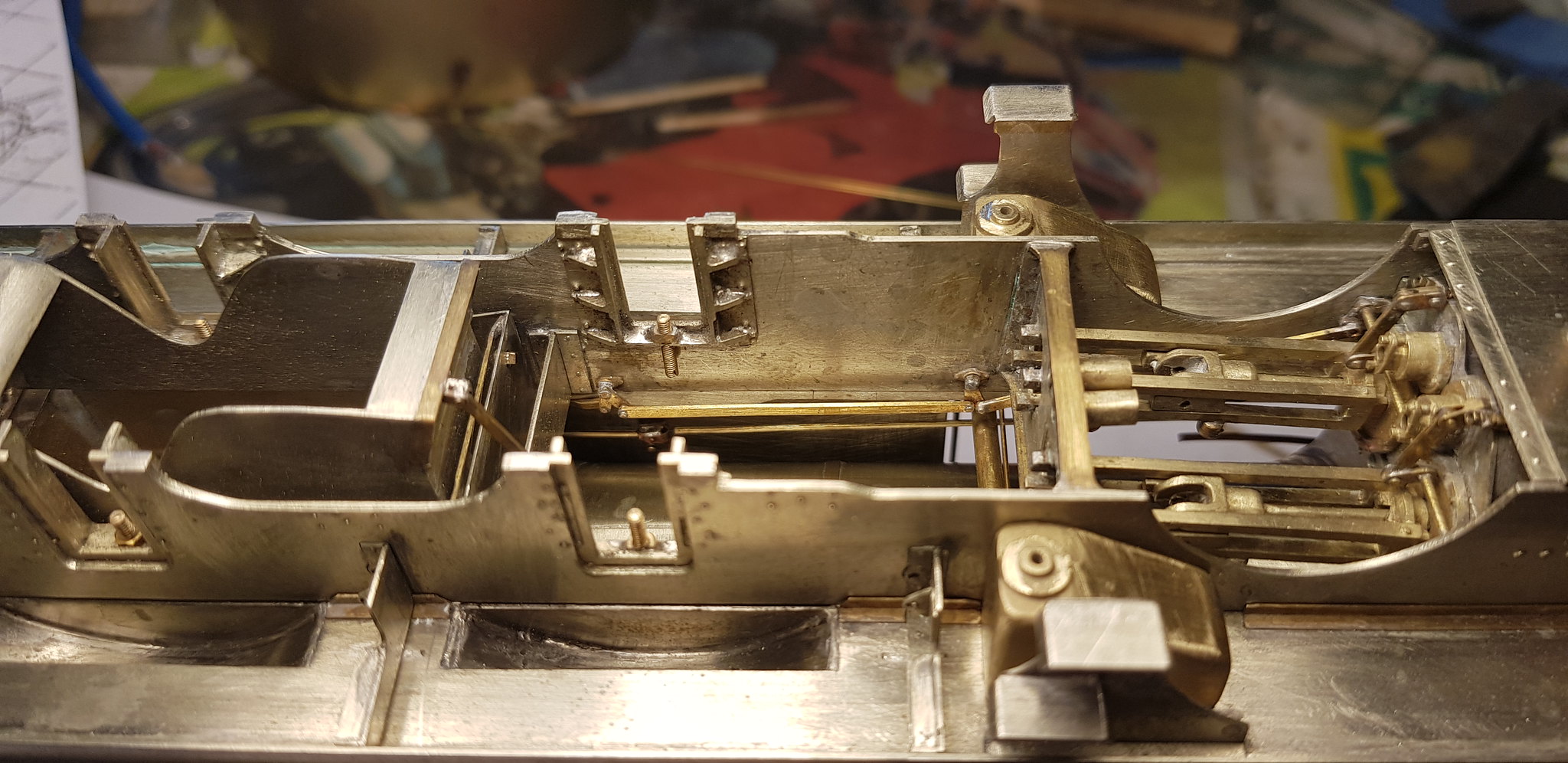

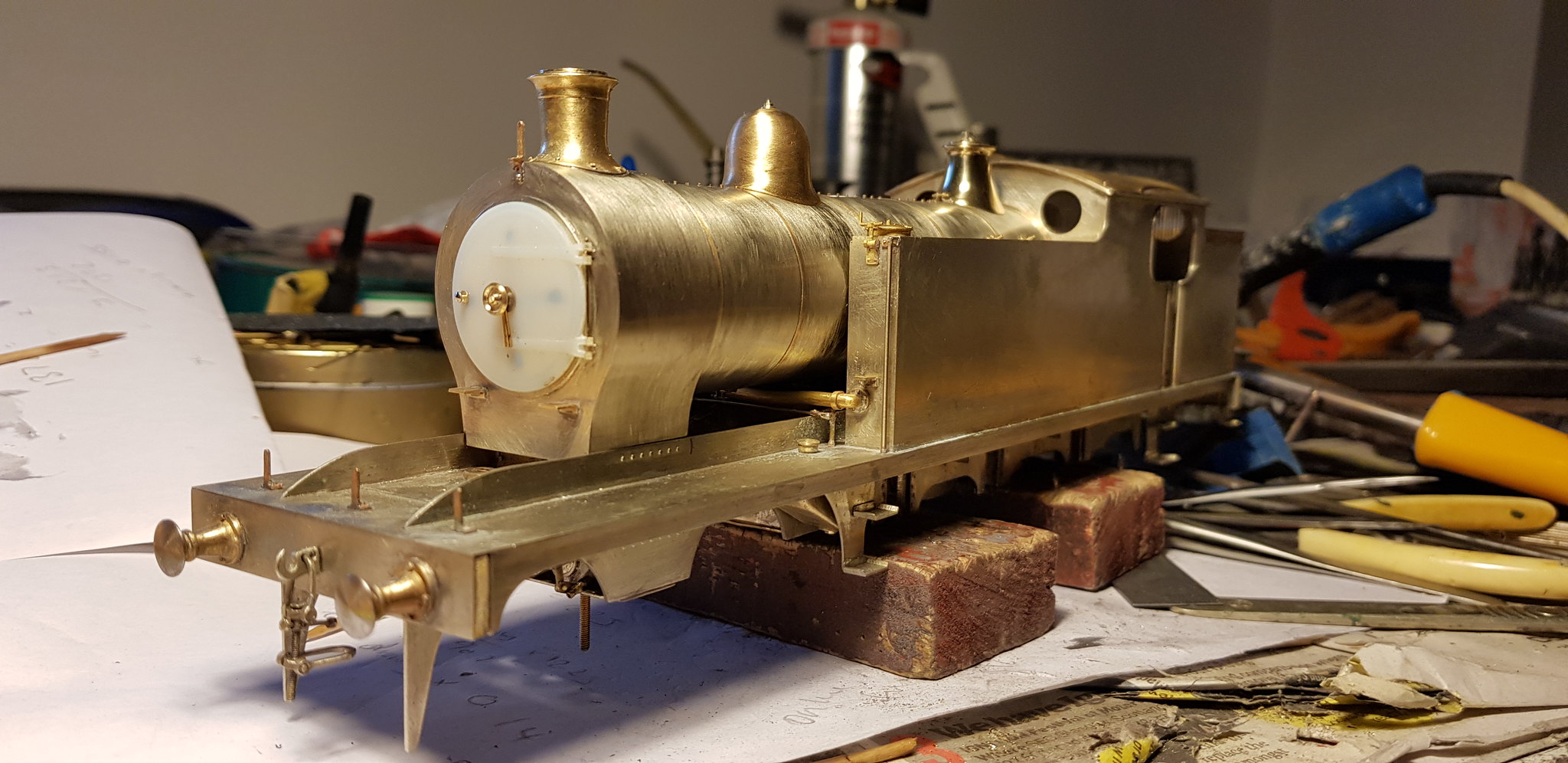

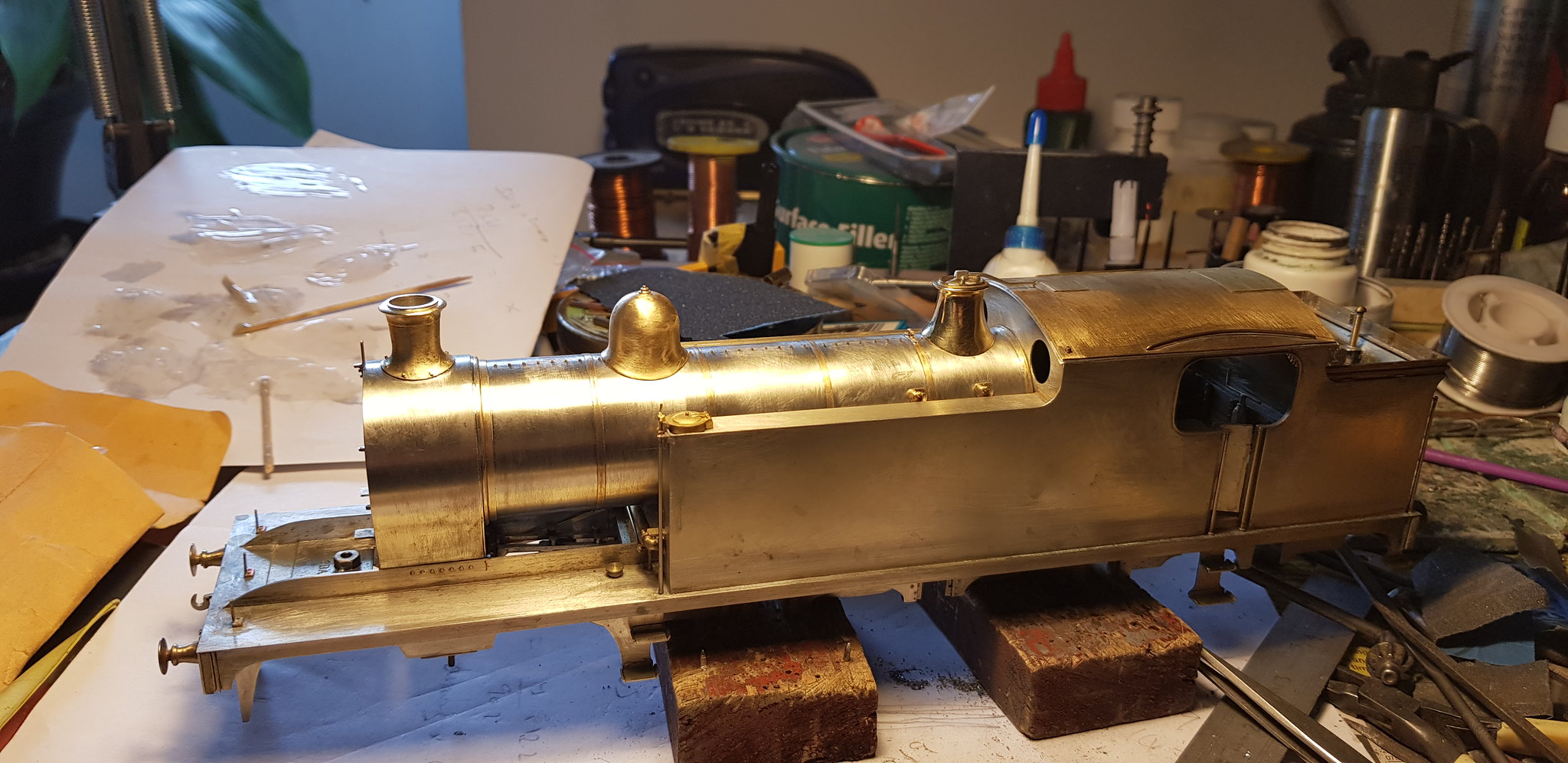

So that's all the main structures of the loco completed. Just a ton of detail to go!

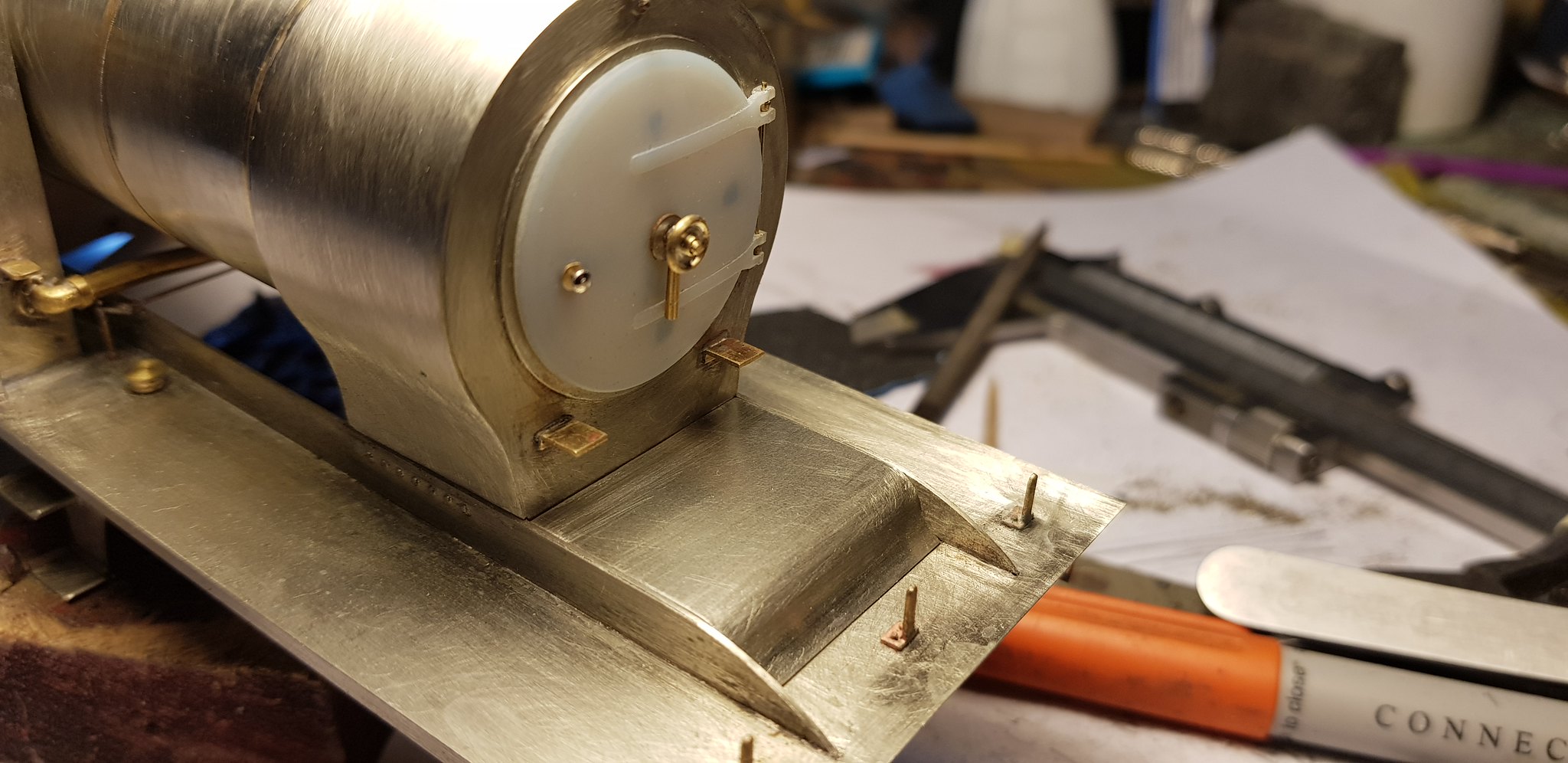

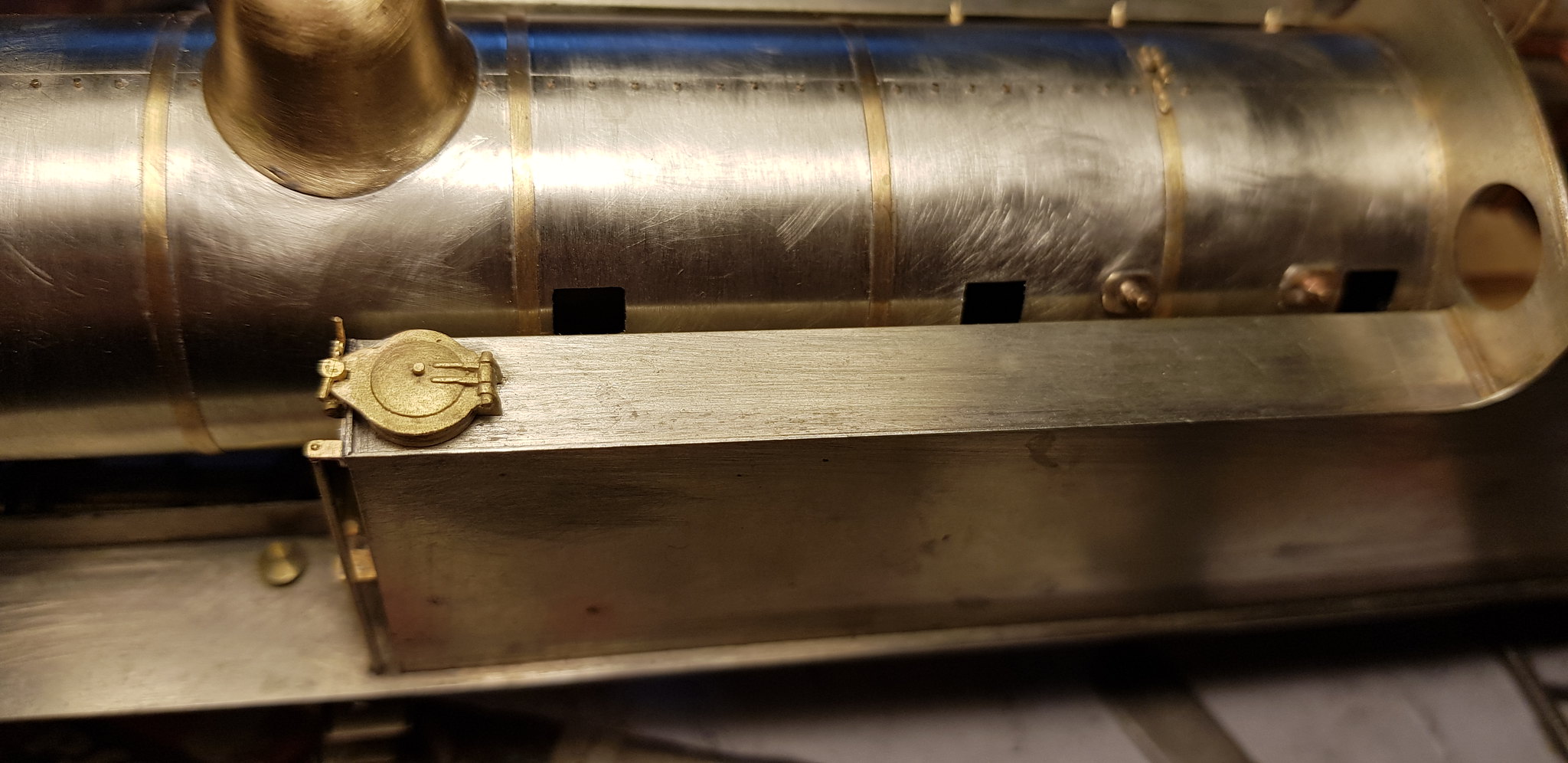

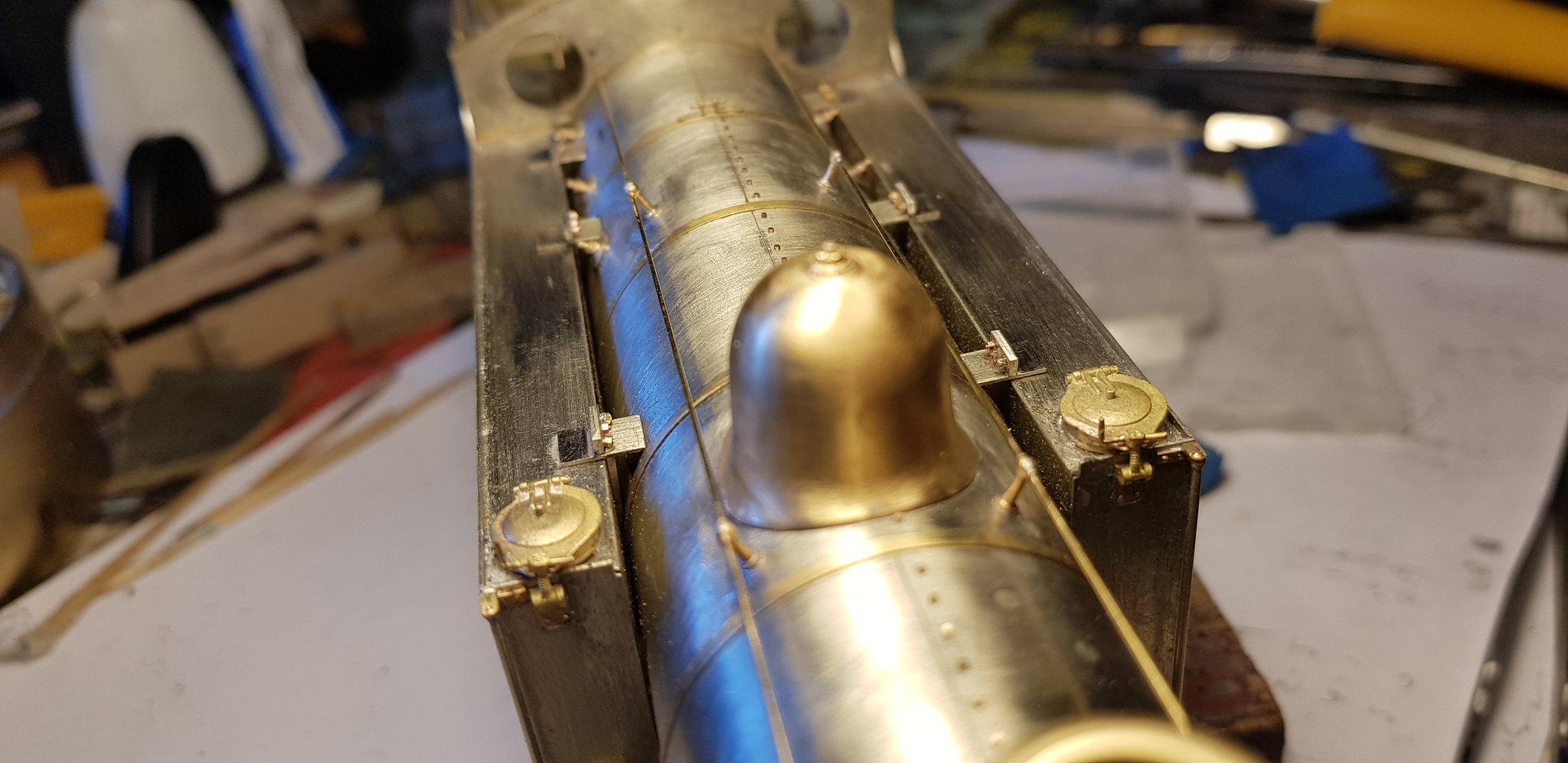

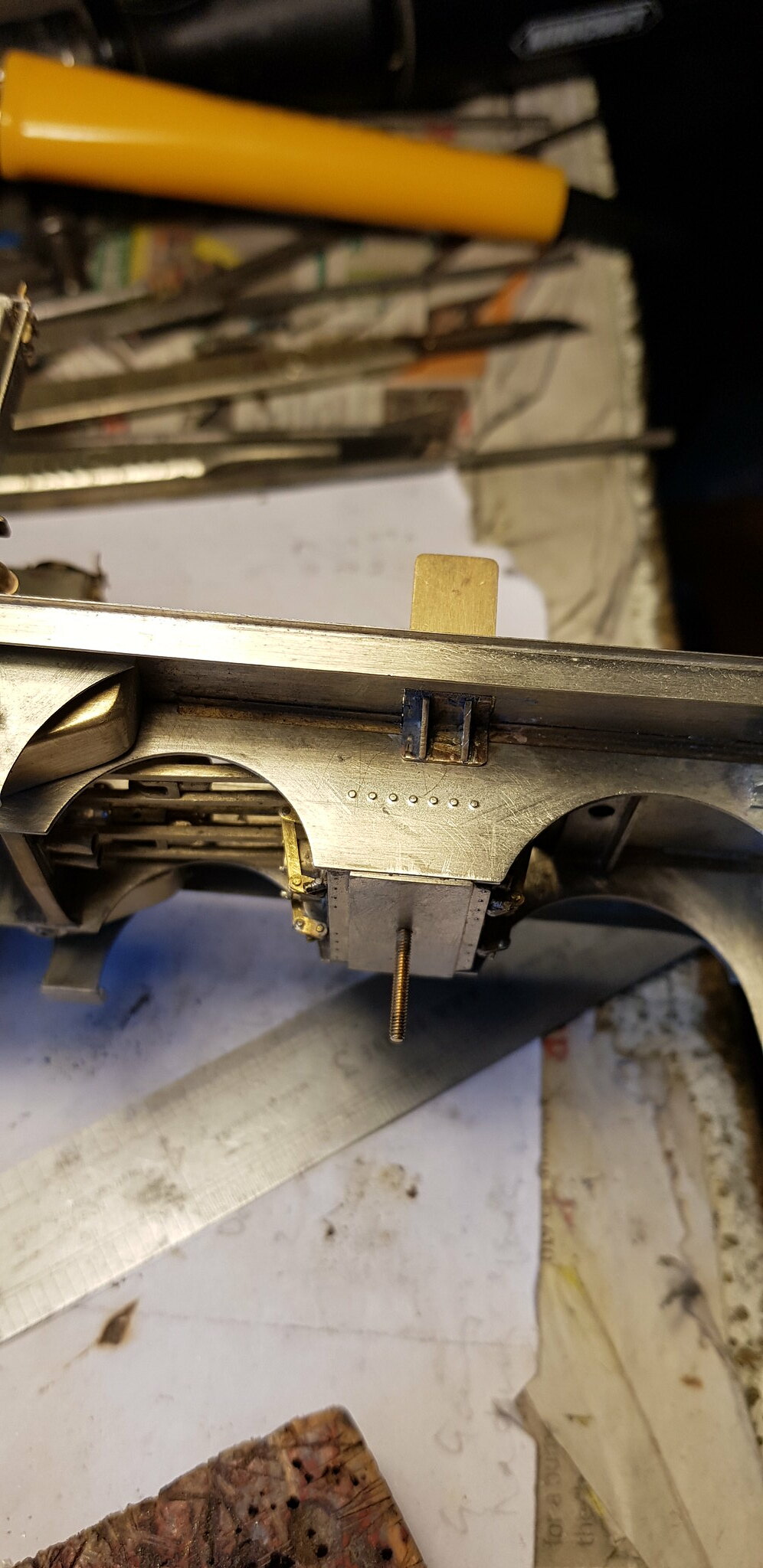

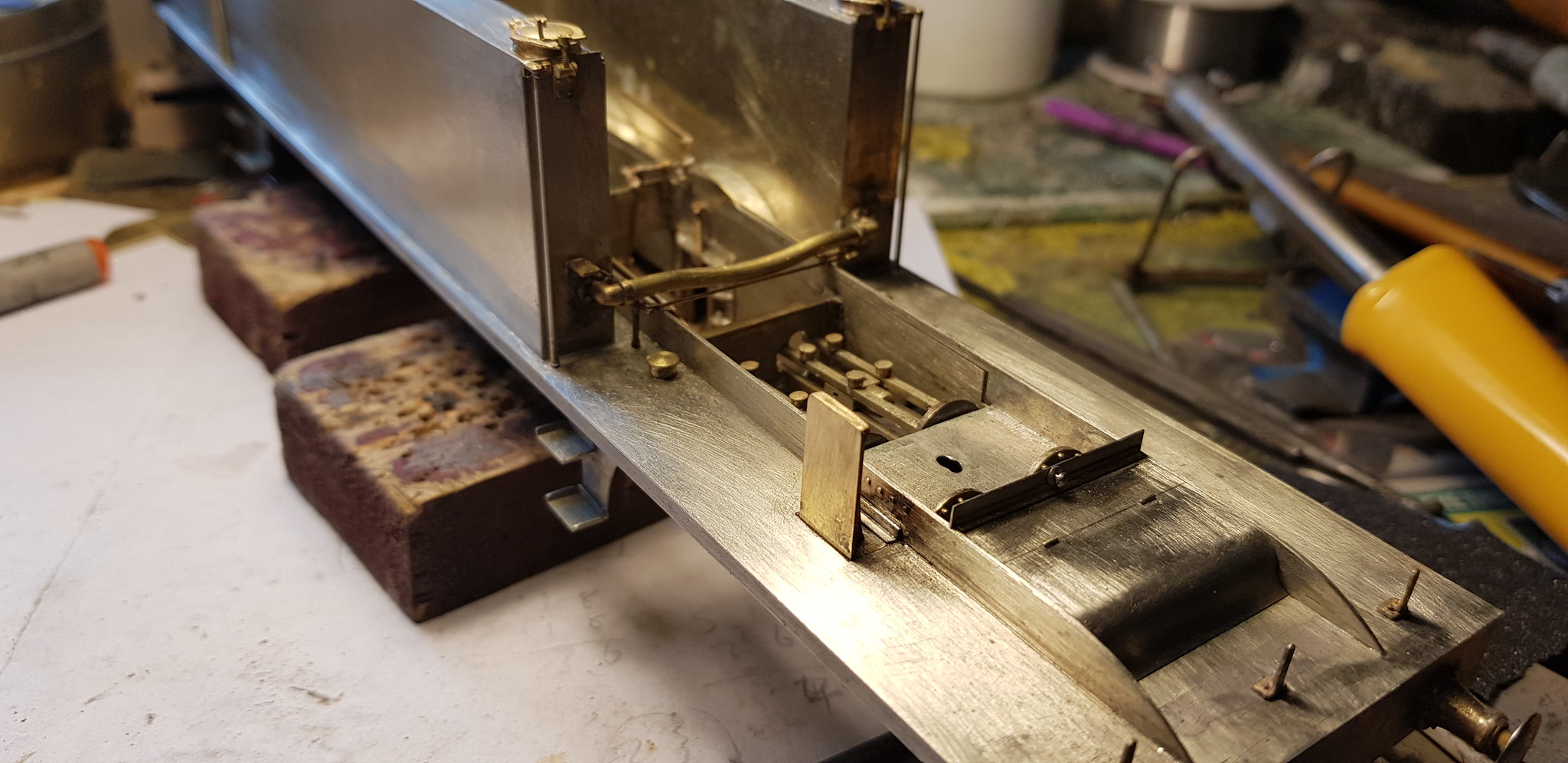

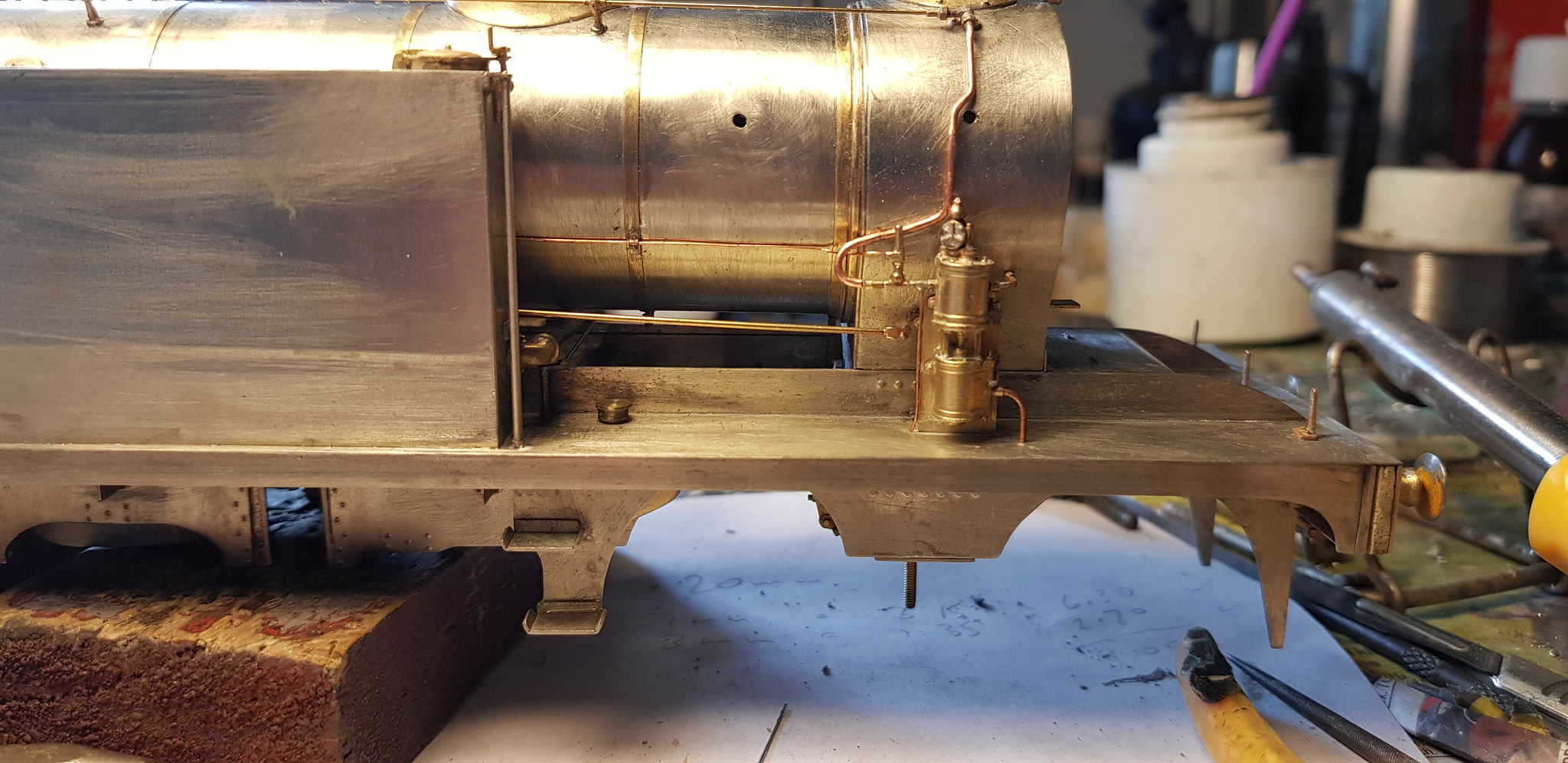

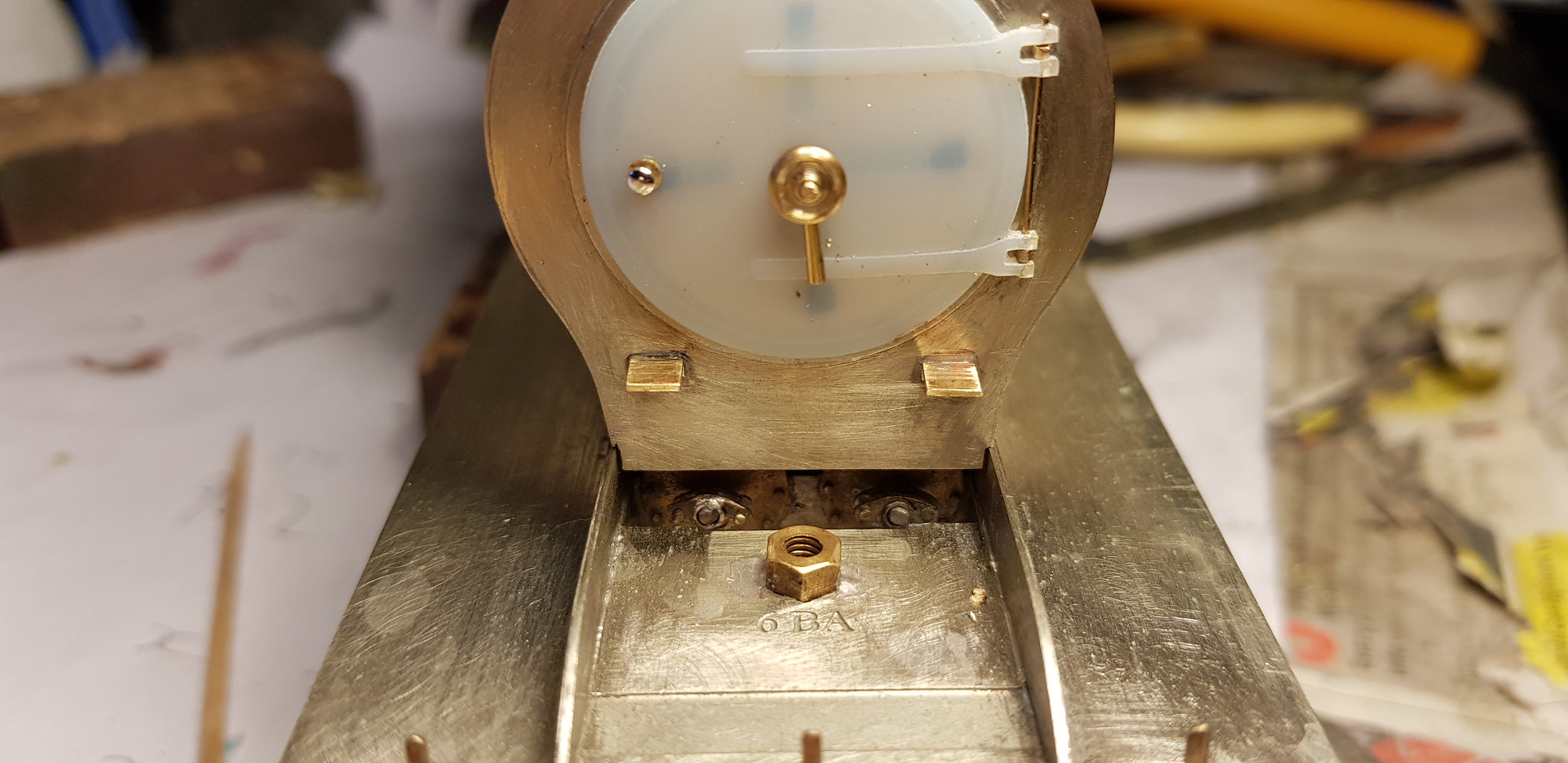

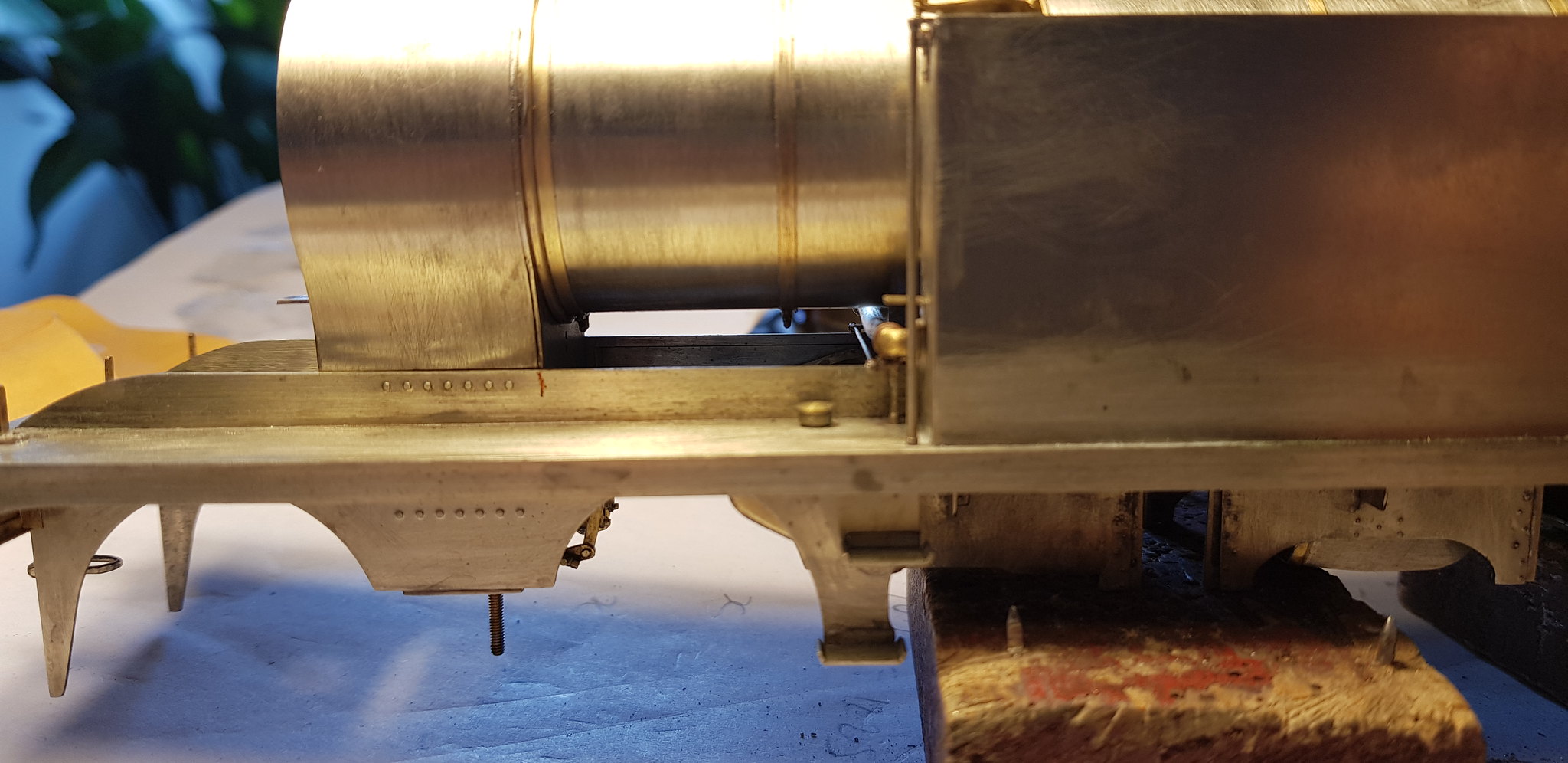

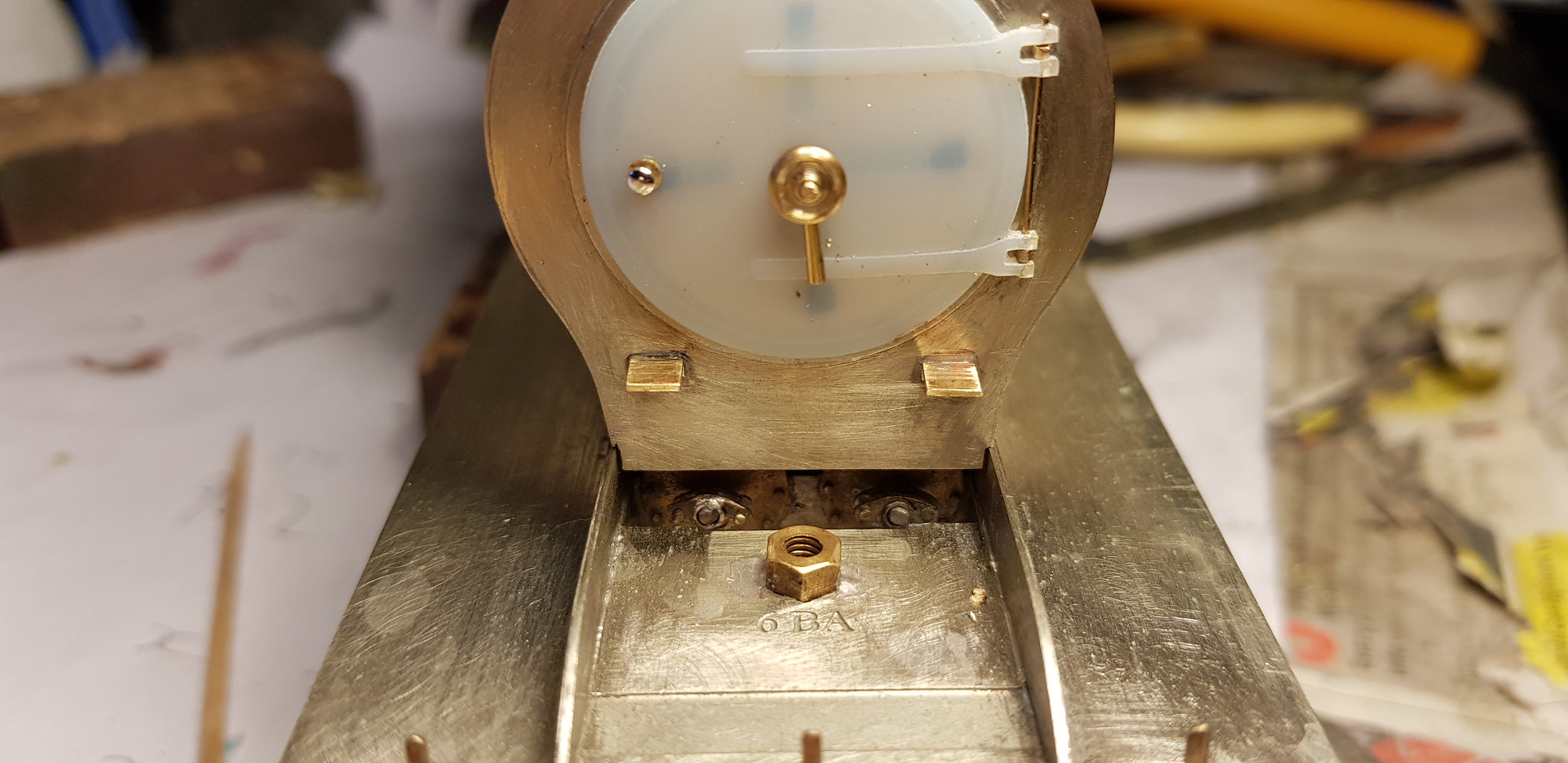

You can see the valve chests for one last time before I make a cover! It captures the look of the prototype I think.

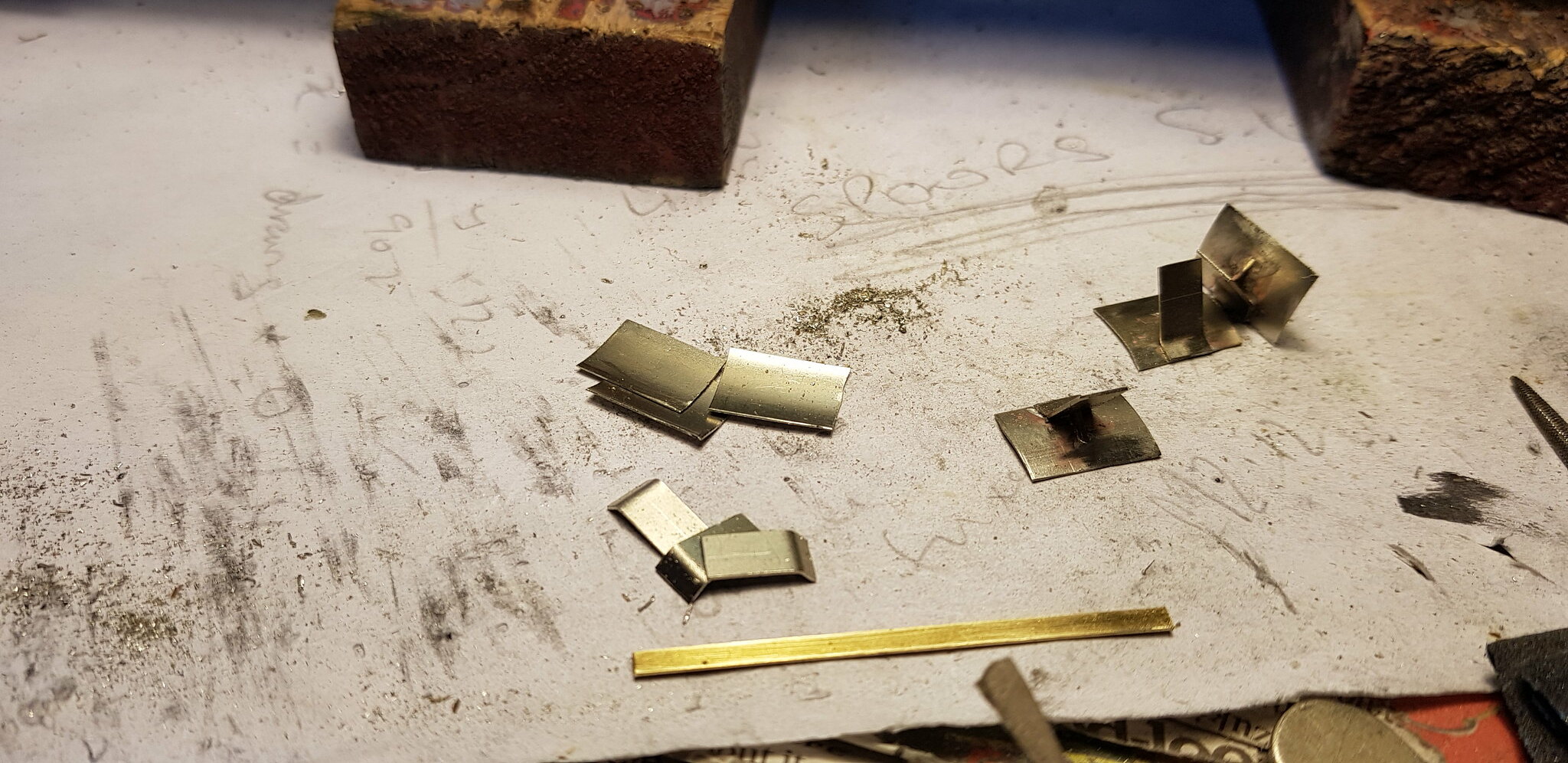

Valve covers and control rods next......

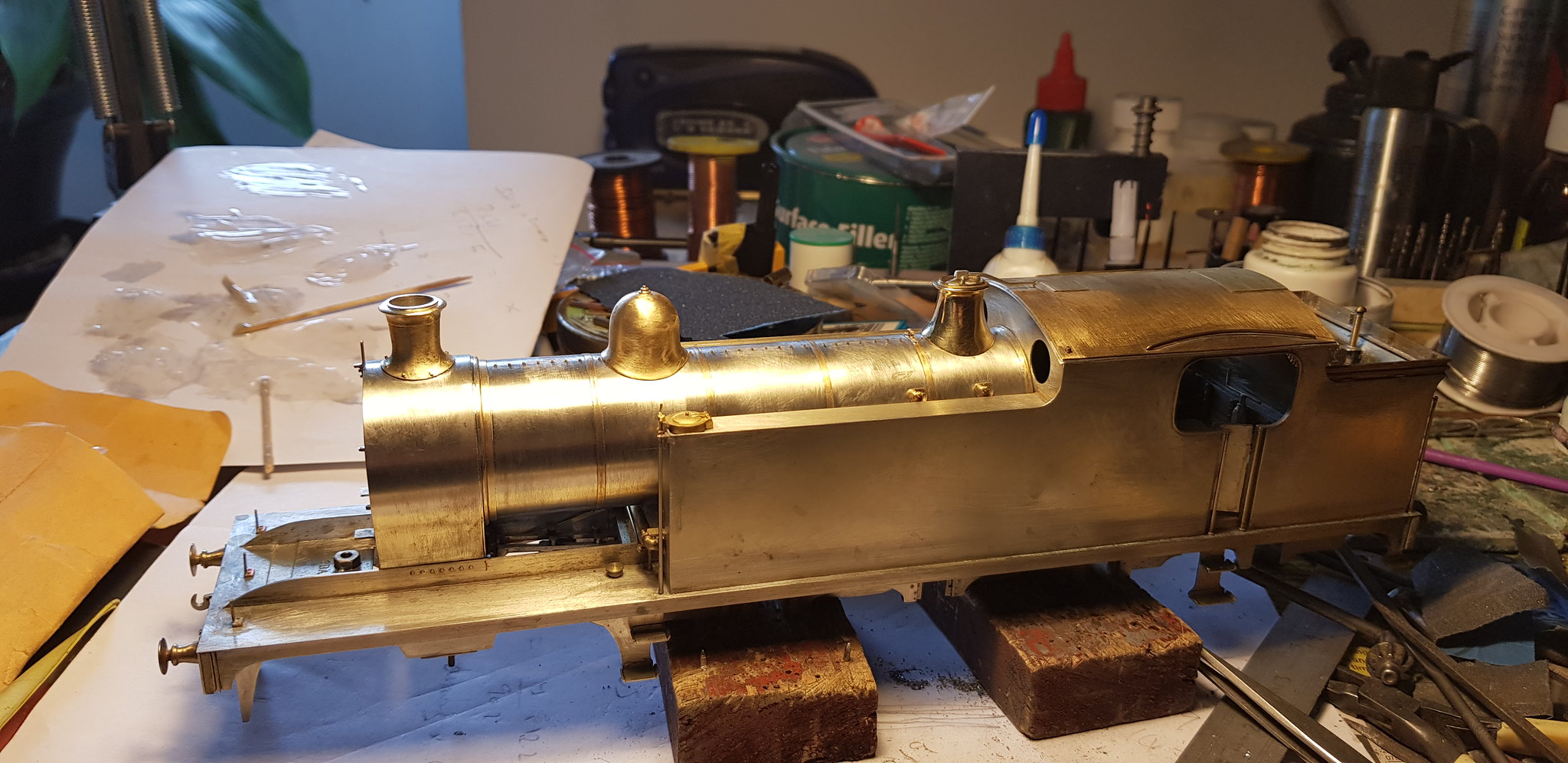

Then the rest of the soldering could be done with the assembly off the rest of the body. I added the polished brass joint cover, the first boiler band, a cleat and the last few screws along the top of the boiler clothing.

So that's all the main structures of the loco completed. Just a ton of detail to go!

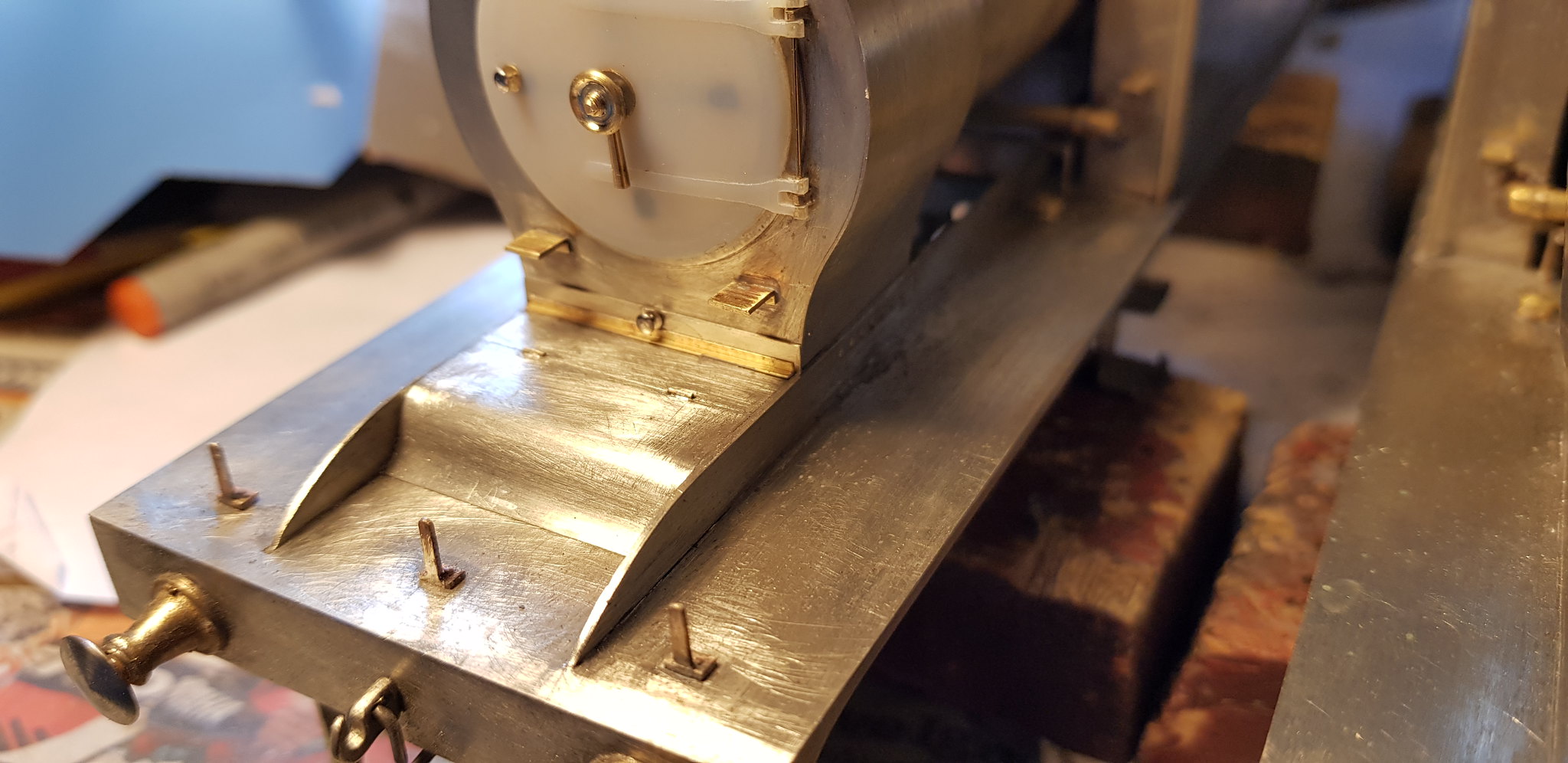

You can see the valve chests for one last time before I make a cover! It captures the look of the prototype I think.

Valve covers and control rods next......