JimG

Western Thunderer

I think I only ever saw ex police velocettes. We're We'y not a little 2 stroke that would hardly pull itself.

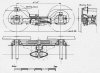

They were an opposed twin, water-cooled, four-stroke, shaft drive. The earlier models were 175cc but the later models, like mine, were 200cc and the Met bikes were 12V. They certainly weren't fast bikes - I think I remember doing anything over 50mph as an occasion - usually downhill.

But they were superbly balanced with a very low centre of gravity. I could roll a cigarette on mine while commuting between Dumbarton and Glasgow.

But they were superbly balanced with a very low centre of gravity. I could roll a cigarette on mine while commuting between Dumbarton and Glasgow.

Jim.