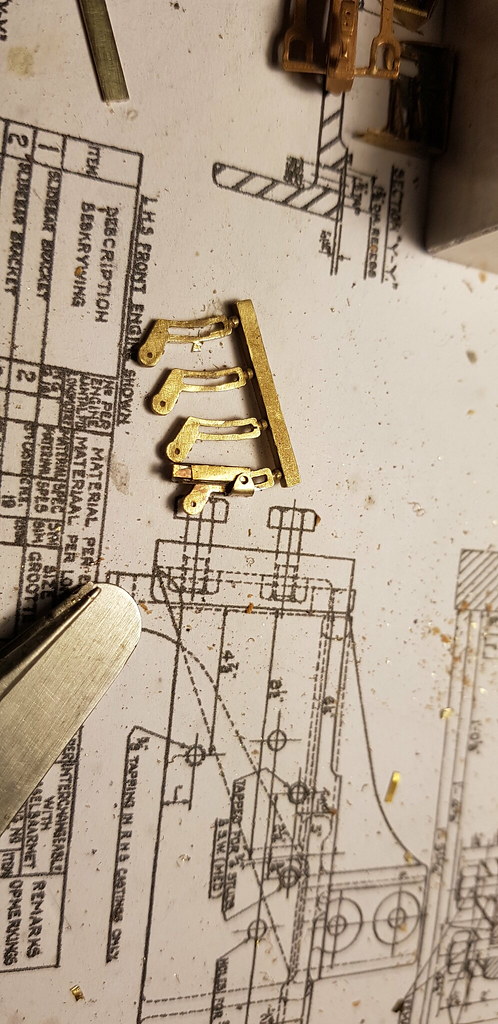

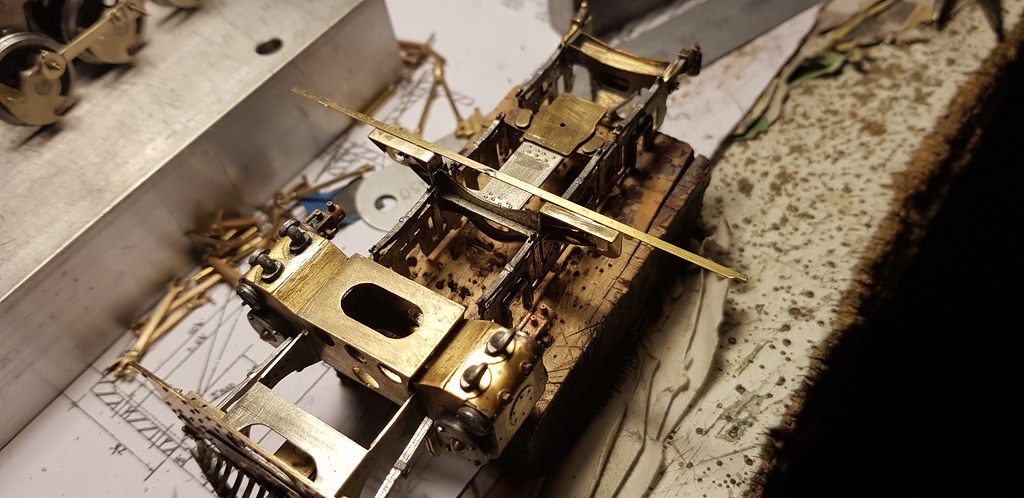

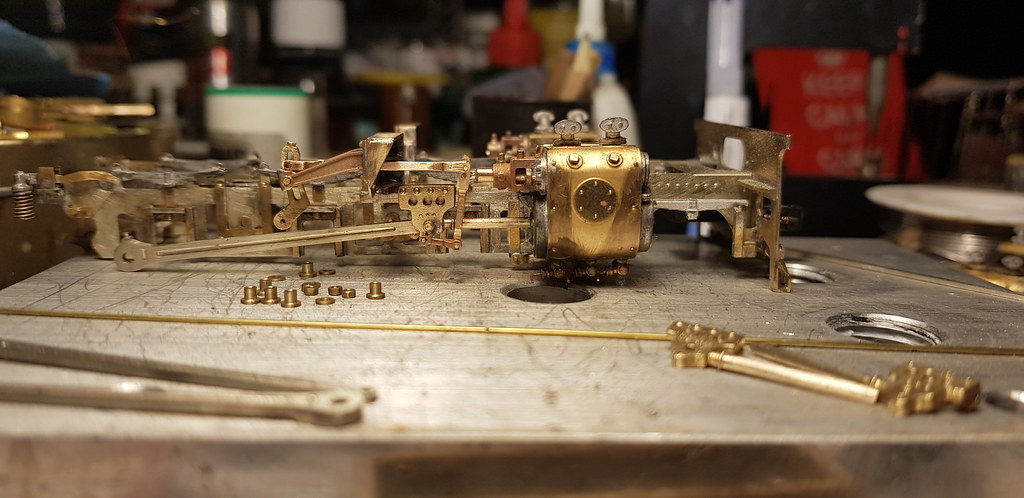

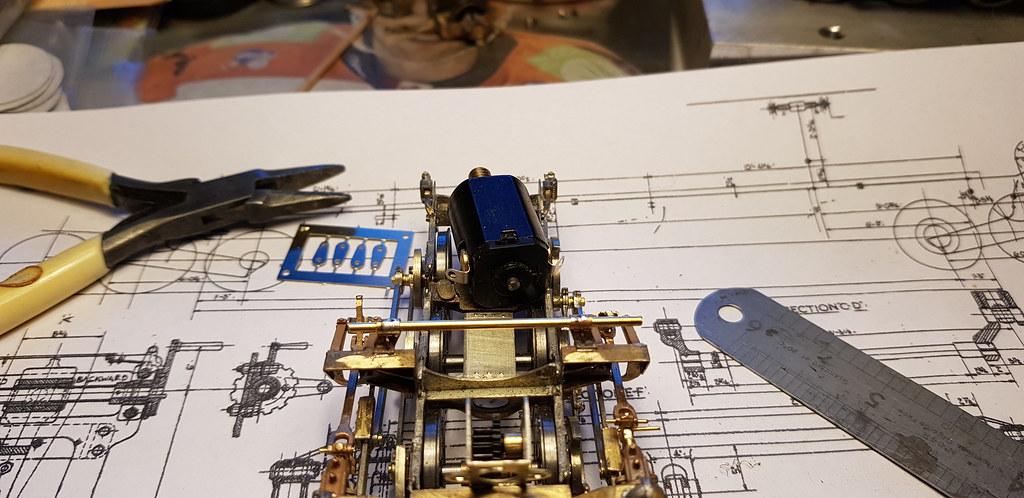

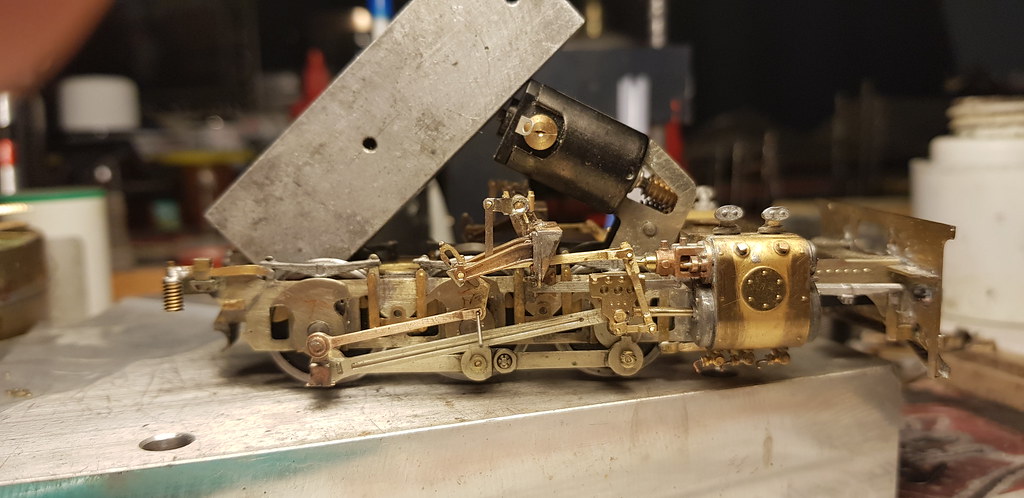

.....fair bit of progress considering it's Christmas. I made some lifting links and attached them to the reversing shaft.

Then I made some drop links and connected it all up.

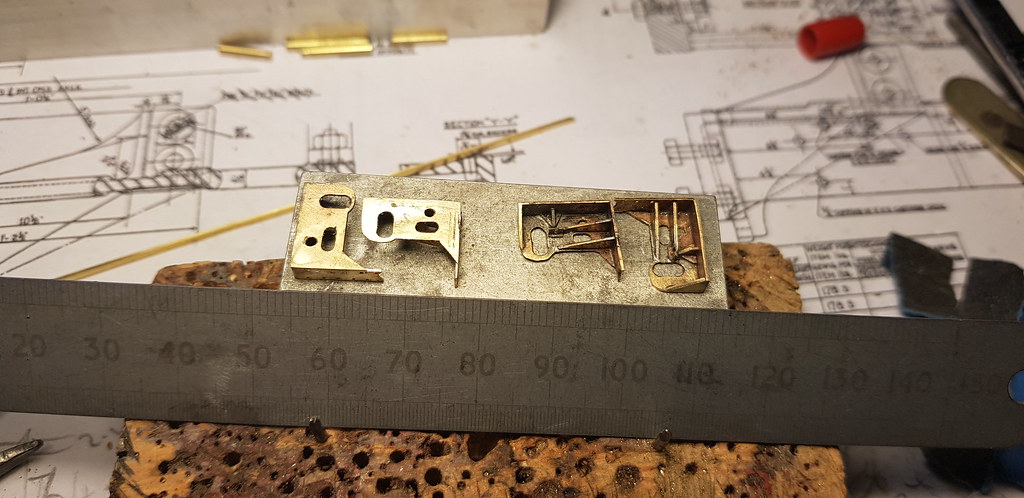

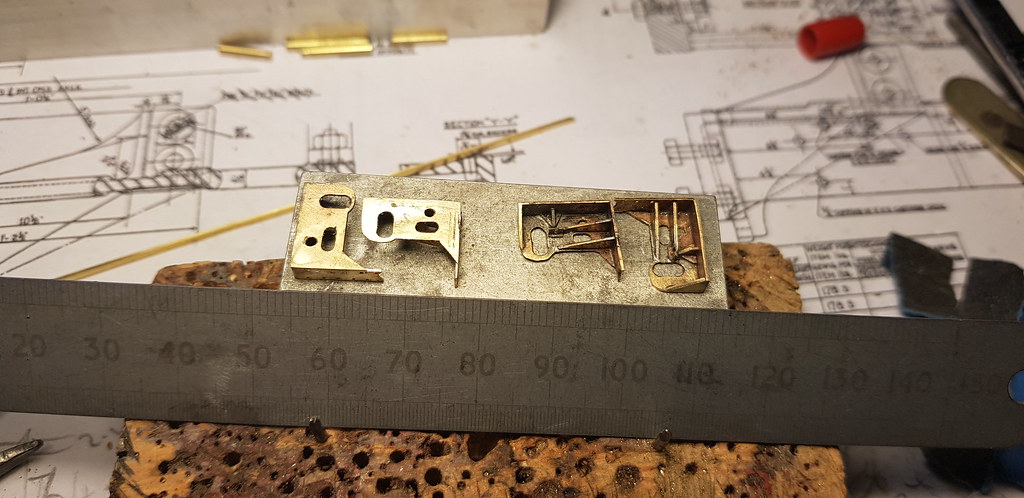

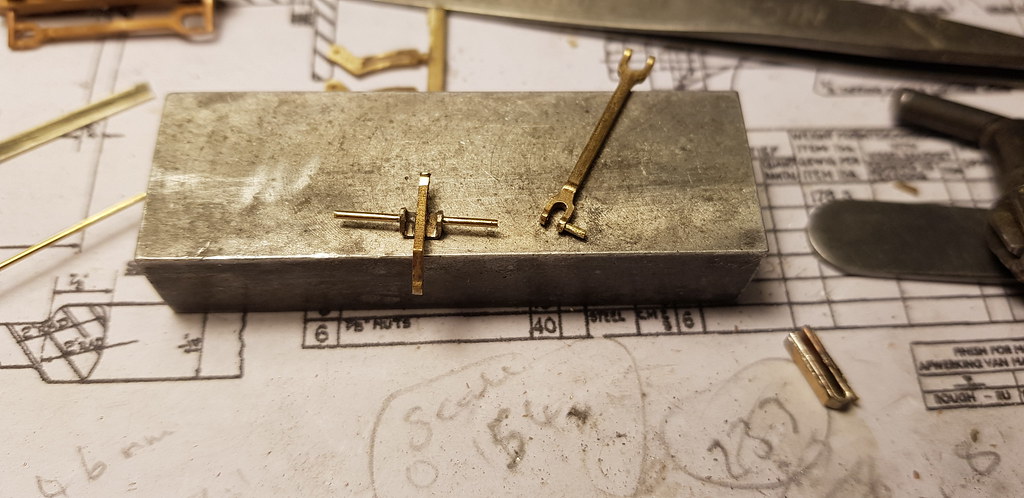

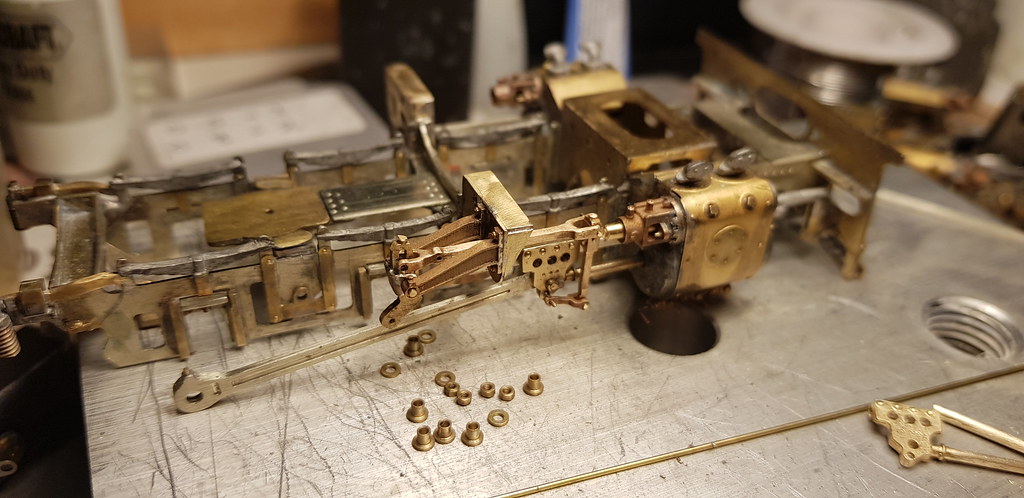

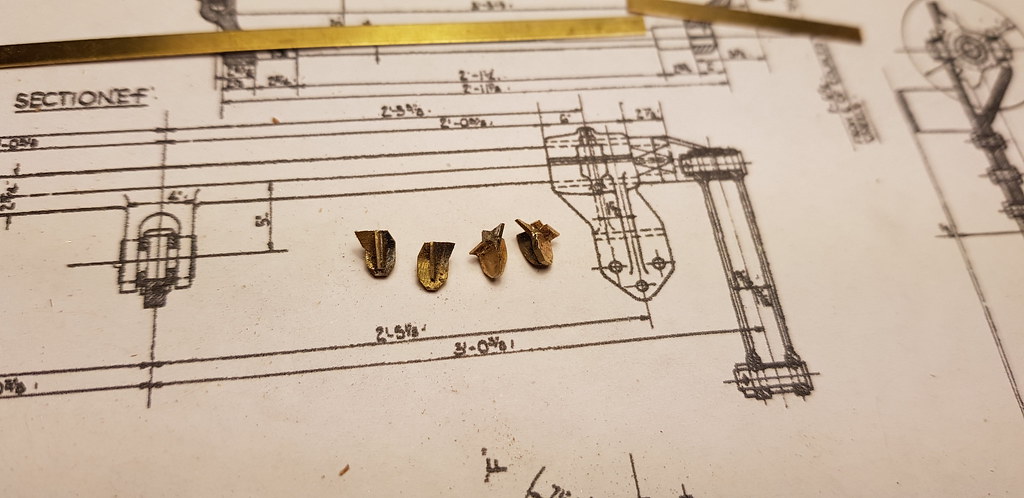

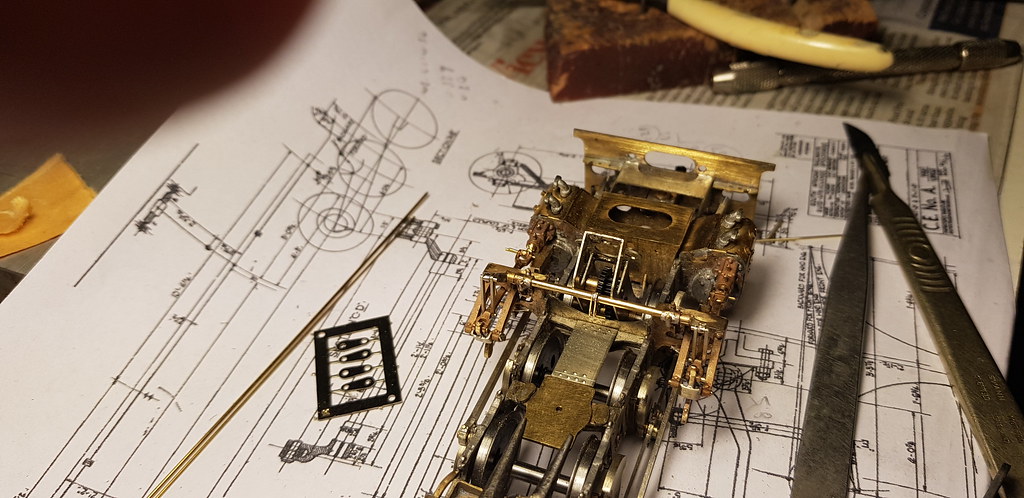

The return cranks (in the frame) supplied were a bit naff, so I made some better ones (below the frame.)

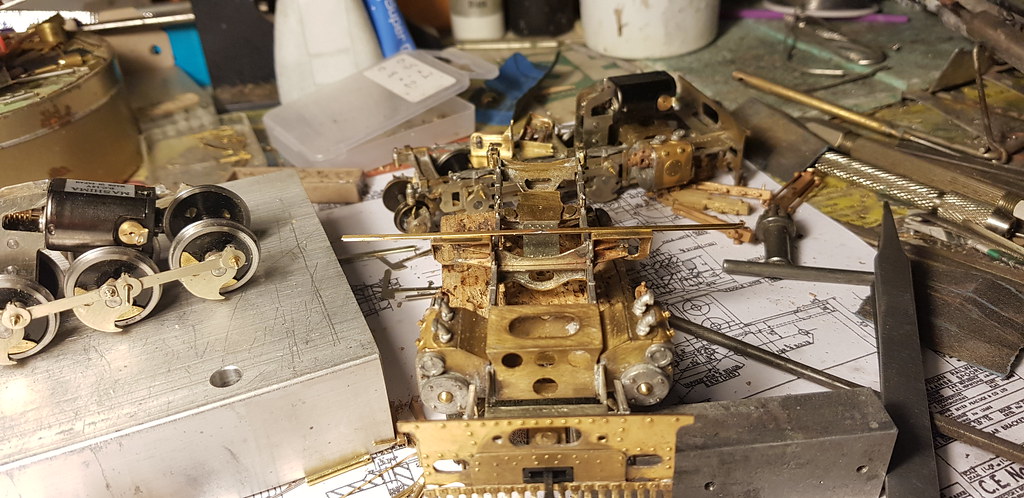

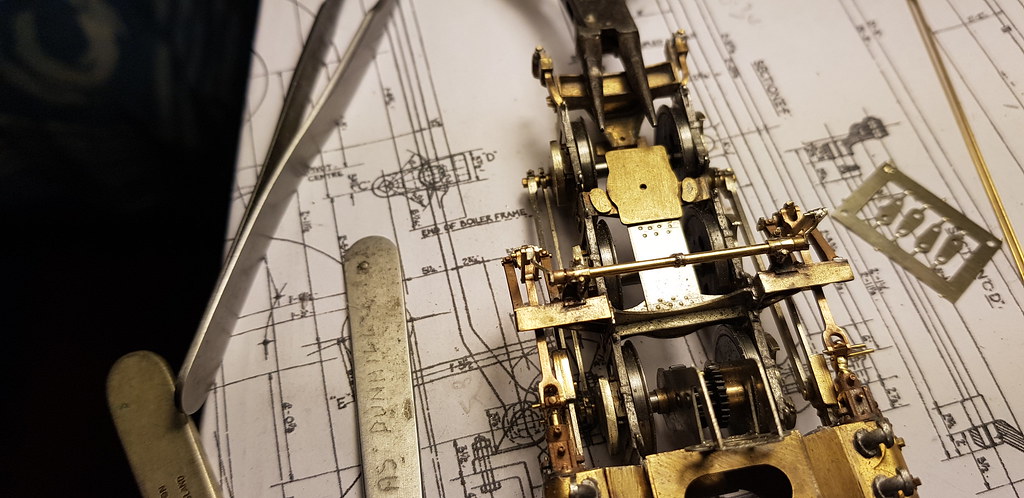

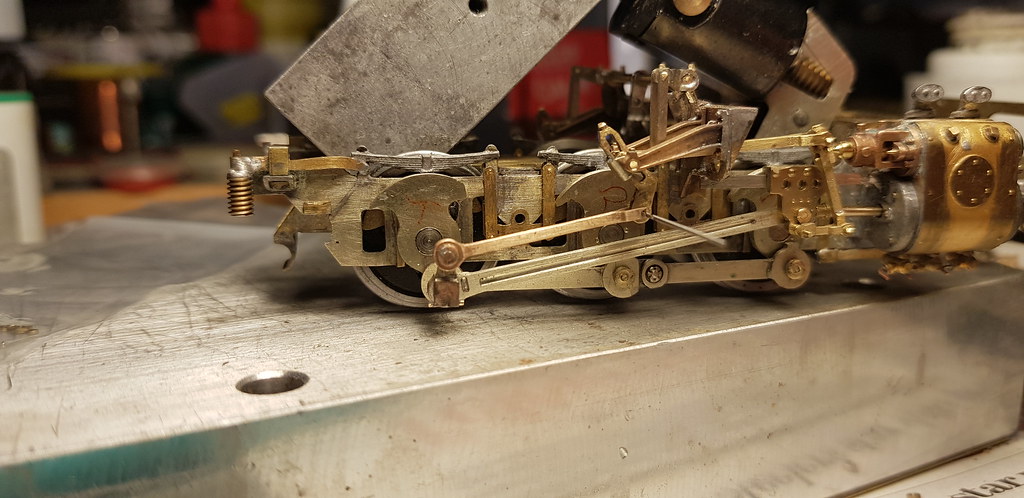

I have to confess to a bit of a cock up. The screws supplied for crankpins were of two different lengths, with longer ones for the return crank. I blindly attached the longer screws to the middle wheels!! I needed a solution for attaching the return cranks to the rear wheels now with the shorter crankpin screw. Bah.

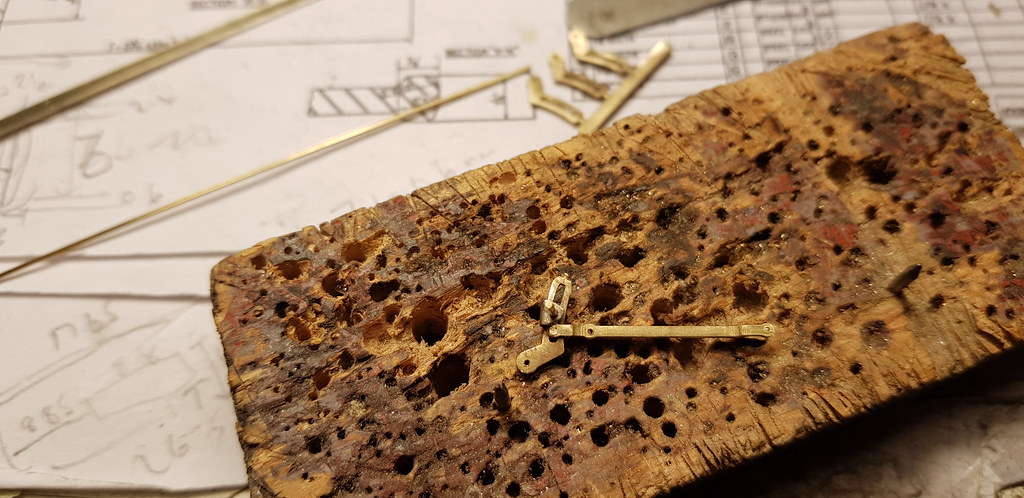

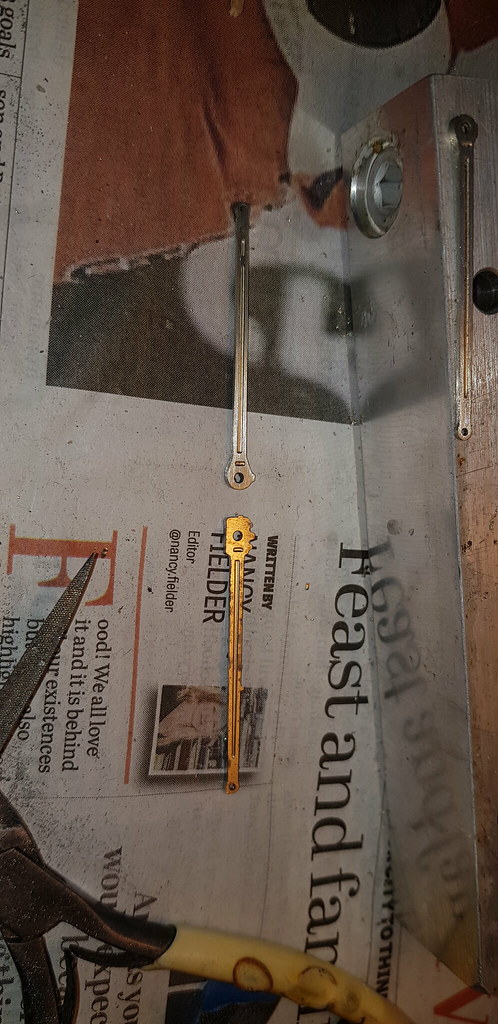

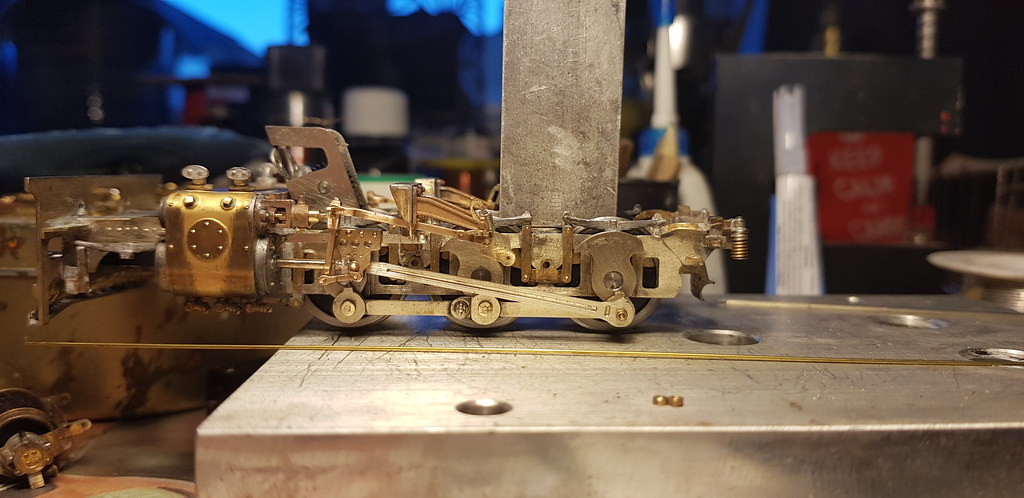

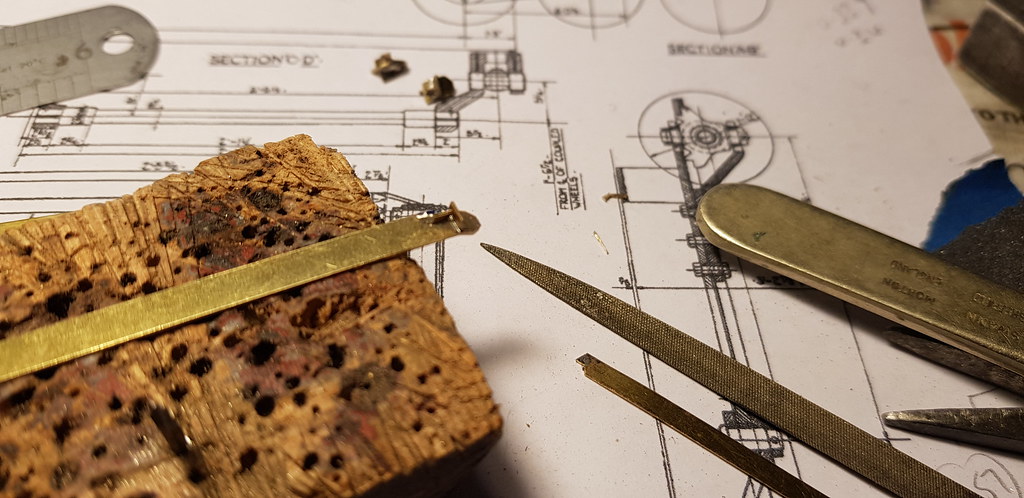

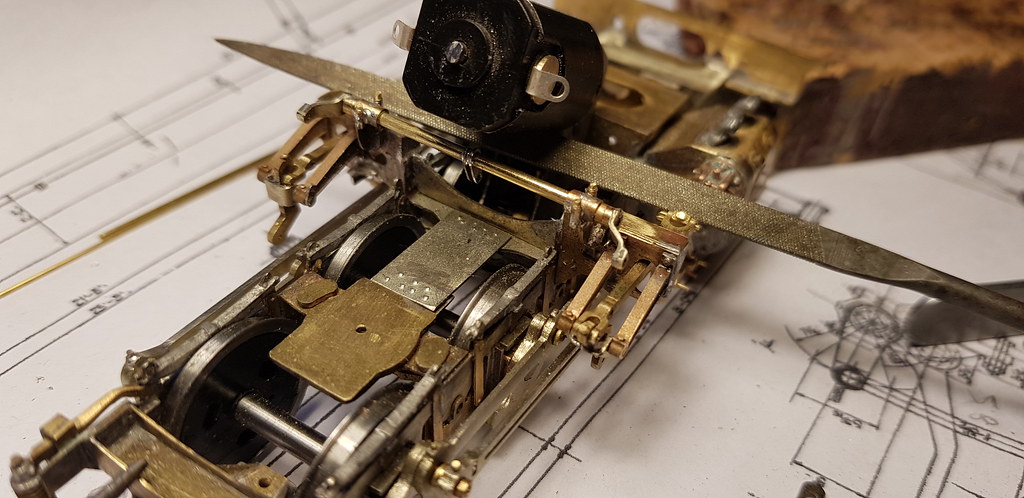

I cut and threaded some rod for the con. rod journal,

and added an appropriately sized spacer.

This was screwed onto the crankpin and the return crank soldered on at a suitable jaunty angle. Actually a bit less than the correct angle so it can be nipped up on final assembly.

Must get round to replacing the drill with an eccentric rod pin.

Happy Christmas all...........