Mrs Mojo keeps wandering off. I keep telling her I am supposed to be trying to earn a living at this modelling malarkey, but she will have none of it. For this reason, progress has been fitful this past week or so.

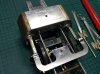

In a fit of madness, though, I did get the brake rigging organised over the weekend.

I am using my usual trick of 14BA bolts, lengths of brass tube as spacers, and nuts to hold it all in place. The theory is by undoing all the nuts, the hangers and cross shafts can all be prised away, allowing wheels to be dropped if required. That's the theory.

The hangers and shoes are made up of a three deck sandwich of etches. I could have got away with forgetting the back half-etch, but it seemed a shame to do that. What I had was a front, with the characteristic scalloped front, a middle part, and a rear part with some details. Looking at photos of the real thing, it's obvious the outer plates were just that, with the shoes hinged between them. To simulate this I filed away the edges of the middle etch to leave a bit of a recess when assembled.

Then I faced the rear and rubbing surfaces with black styrene sheet, in an attempt to avoid shorting. The brake hangers literally hang just where the real ones should, and consequently there is little to no gap between shoe and tyre. This was made worse by me adding 20 thou of styrene! After some judicious scraping and fettling, the brakes sat fairly happily with their wheels, so I could fit the cross shafts. In time-honoured fashion these were made of etched plates and wire.

Well, it sort of worked in the end. It will have to do. I really need to work on my brake rigging, because no matter how careful I am, it never seems to sit straight or true.

The connection to the handbrake and vacuum brake under bunker is notional. So far, I have found a way to fit the over-size cylinder so I can still get the bolt in to hold the frames and body together. The way (weigh?) shaft is brass wire, but I have failed to locate suitable components with which to complete the fittings properly.

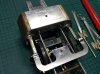

Moving on, time to trial fit the couplings rods.

The client had substituted third party milled rods, origin unknown. The etched rods were not in the box, and knowing how hard it would be to get replacements from JLTRT, I figured I would have to go with what I had.

I tidied the rods up, polished to outer faces so file marks weren't obvious, and also managed to get the connecting rods attached to the crossheads without too much swearing. So far, so good. Obviously, a 12BA bolt and nut will have to substitute for the castellated nut that holds the real ones, but I'm sure it'll pass muster. I am awaiting some proper crankpin nuts from Scotland, so I can't do the recessed leading nuts yet.

First problem, though, was the rods clout the brake hanger retaining nuts. A washer shim isn't enough to pull them out, so it looks like I shall have to kill the backs of the rods to thin them.

Another problem is I will need to carve a chunk out of the back of the cylinder castings to clear the brake hangers at the front. So, as kind of expected, there's going to be all manner of compromise involve in order to get everything to fit together round the front.

I want all this sorted out now so I can clean it all up and paint it before I fit the plunger pickups. It's currently looking like I will run out of puff in this build soon, and I'll need to pick up another one to keep me going. Hang on! Mrs Mojo has wandered off again! Oi! Come back here!