You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm Pencarrow - Cornish BR(S)

- Thread starter Pencarrow

- Start date

Peter Cross

Western Thunderer

I thought you'd started another layout..

Pencarrow

Western Thunderer

Pencarrow

Western Thunderer

OK, after a two-month hiatus of modelling on Pencarrow I've spent the morning evicting spiders and trying to remember where I got too.

I've had help from Simon behind the scenes and this has helped restart the mojo - many thanks.

A question for the track clever... I'm building track to 31.5mm gauge and 1.5mm flangeways at the crossing but what gap should I allow between the blade and stockrail at the tie-bar?

I automatically started thinking 1.5mm but then memories resurfaced that it should be more to allow for the blade curving towards the stockrail. I can't find what I'd previously read though.

Any thoughts appreciated.

I've had help from Simon behind the scenes and this has helped restart the mojo - many thanks.

A question for the track clever... I'm building track to 31.5mm gauge and 1.5mm flangeways at the crossing but what gap should I allow between the blade and stockrail at the tie-bar?

I automatically started thinking 1.5mm but then memories resurfaced that it should be more to allow for the blade curving towards the stockrail. I can't find what I'd previously read though.

Any thoughts appreciated.

Last edited:

...catch point out.

Pencarrow

Western Thunderer

Christmas video - sprouts

Jan 2018 wiring begins

Pencarrow

Western Thunderer

Droppers are all installed using 16/0.2mm wire and soldered to the underside of the rail.

Main feeds are 32/0.2mm thin wall wire in delightful, but not very original, red and black.

Droppers are soldered to the main feeds and then a chocolate box is slid over which hides the exposed wire and also provides a method of fixing the wires to the board.

Main feeds are 32/0.2mm thin wall wire in delightful, but not very original, red and black.

Droppers are soldered to the main feeds and then a chocolate box is slid over which hides the exposed wire and also provides a method of fixing the wires to the board.

Pencarrow

Western Thunderer

Pencarrow

Western Thunderer

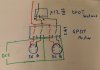

Each board is being wired as a stand alone unit, each with its own connection cable back to the control panel.

Board 1, the one with the grainstore and station buffer stops, has four sections. Board 2 has the most sections with 7.

Them wot knows electrics will note that the switches are wired using a common return (red wire) with the black being switched. That means, on the power supply board to control panel cables I'll need up-to 8 wires (board 2 will have 1 red and 7 black).

My first thought was to use bog standard d-sub sockets and ready made vga cables. The digging I did revealed that although the d-sub it's and sockets could take an appropriate ampage, the ready made cables really weren't up to it. There appeared to be a good chance of the single red return wire getting cooked in DCC mode.

I did think of wiring 2 pins as the common return but then found that many of the pre-made vga cables already group pins using 3 each for RGB.

Looking around for other options I found these GX16-9 plugs and sockets. Robust, professional units used for aeronautical and microphone applications.

It would mean making my own cables using 8-core multi-core cable (7x1mm2 and 1x2mm2) with the 1x2mm2 used for the common return.

The max interconnect run between boards and control panel is 4m by the way...

Still some thinking to do on this I think.

Board 1, the one with the grainstore and station buffer stops, has four sections. Board 2 has the most sections with 7.

Them wot knows electrics will note that the switches are wired using a common return (red wire) with the black being switched. That means, on the power supply board to control panel cables I'll need up-to 8 wires (board 2 will have 1 red and 7 black).

My first thought was to use bog standard d-sub sockets and ready made vga cables. The digging I did revealed that although the d-sub it's and sockets could take an appropriate ampage, the ready made cables really weren't up to it. There appeared to be a good chance of the single red return wire getting cooked in DCC mode.

I did think of wiring 2 pins as the common return but then found that many of the pre-made vga cables already group pins using 3 each for RGB.

Looking around for other options I found these GX16-9 plugs and sockets. Robust, professional units used for aeronautical and microphone applications.

It would mean making my own cables using 8-core multi-core cable (7x1mm2 and 1x2mm2) with the 1x2mm2 used for the common return.

The max interconnect run between boards and control panel is 4m by the way...

Still some thinking to do on this I think.

Last edited:

Pencarrow

Western Thunderer

Chris,

Happy to help!

Best

Simon

Much appreciated.

Pencarrow

Western Thunderer

I did look at those Dave - automotive electric connections. How have you got on using them?

What put me off, although they are still on the shortlist if the GX16-9 sample proves unsuitable, is that there didn't seem to be any way of mounting the sockets on the rear of the control panel. Also, although separate wires are fixed to a pin and the pin caught in the body, the main multi-core cable isn't clamped into the body.

The look great though for connecting components such as point motors, making it quick and easy to swap a unit out.

If you have any experience from using them I'd be pleased to hear it.

Pencarrow

Western Thunderer

Chris, I bought some of those connectors for Crosscombe Magna. Problem with the joiners with large number of pins is that the surface for soldering the wires to is very small.

I need to try and find some with a larger surface area..

JB.

I had similar concerns so I've ordered one pair to see what they are like.

daifly

Western Thunderer

ChrisI did look at those Dave - automotive electric connections. How have you got on using them?

I haven't used them yet but have previously used something very similar without problems. These CPC ones have keying to prevent connecting plug and socket the wrong way round. If that doesn't give you the protection that you require, the pins and sockets can be mounted on either the plug or receptacle in any configuration giving 15! possible combinations! (that's 1,307,674,368,000 according to my calculator!)

The receptacle is designed to be panel mounted if required. See here.

As you pointed out, there is no cable clamp facility. I suppose it depends on whether you are taking the boards apart frequently or just require the facility to separate them occasionally as required.

Dave