Dave

Western Thunderer

I'm Dave and I'm an industrial locomotive kit addict...

I bought another one, another Peckett. I really shouldn't be building soft southern engines, being Leeds born Iought to be building Hudswells and Hunslets, but I couldn't help it.

The kit is from Agenoria and builds Henry Cort, as supplied to the Ebbw Vale Steel & Iron Co. in 1903, although I won't be building mine as that particular engine.

The kit is supposed to be built as a rigid chassis and no provision is made for springing or compensation so I've started from scratch on that.

Some lumps of brass that I hacksawed from bar.

And then sqared off in the miller and drilled holes in...

To make into hornblocks to take ball bearings.

Horn guides made from brass angle and the portion of frames with the holes for the usual plain brass bearings cut away. The blocks have now had slots milled in two opposite sides to locate them laterally in the frame plate.

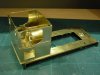

The chassis as far as I've taken it. The spring guides are made from the inserts from electrical connectors and will be either blocked up at the top to retain the coil springs, or have inserts and screws to retain the springs and adjust the ride height.

Sure it's overkill for a 4-wheeler - I could have kept the plain bearings and fitted simple 3-point compensation but I like messing about with these things.

I bought another one, another Peckett. I really shouldn't be building soft southern engines, being Leeds born Iought to be building Hudswells and Hunslets, but I couldn't help it.

The kit is from Agenoria and builds Henry Cort, as supplied to the Ebbw Vale Steel & Iron Co. in 1903, although I won't be building mine as that particular engine.

The kit is supposed to be built as a rigid chassis and no provision is made for springing or compensation so I've started from scratch on that.

Some lumps of brass that I hacksawed from bar.

And then sqared off in the miller and drilled holes in...

To make into hornblocks to take ball bearings.

Horn guides made from brass angle and the portion of frames with the holes for the usual plain brass bearings cut away. The blocks have now had slots milled in two opposite sides to locate them laterally in the frame plate.

The chassis as far as I've taken it. The spring guides are made from the inserts from electrical connectors and will be either blocked up at the top to retain the coil springs, or have inserts and screws to retain the springs and adjust the ride height.

Sure it's overkill for a 4-wheeler - I could have kept the plain bearings and fitted simple 3-point compensation but I like messing about with these things.