Steph Dale

Western Thunderer

Steph's WR Workbench - Springside 2251

Well, the title to this thread is a phrase I never imagined I'd be putting together. In fact putting my name in any proximity to anything WR would have caused a fairly extreme reaction until fairly recently. Two things have changed this and I now have a few WR locos in the 'to do' pile: a 'Duke', an 'Earl' (note, I didn't say 'Dukedog', so I'm learning!) and this 2251...

The two changes? Well, modelling the Romsey-Southampton stretch of the Southern requires a small number of WR locos to work the inter-regional trains and the second thing is reading 'Locomotive Adventure' by Harry Holcroft. A 43xx may well follow after I realised Holcroft's involvement.

So with another thread on making up the inside valvegear up and running, this thread is much more about the constructional bits and pieces, the updates, trials, tribulations and general ego-trip that these things tend to be. So here's where I got up to, about half an hour ago after some months of fiddling, research, etc. and a couple of evenings actually at the bench:

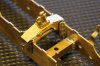

It's now got to come apart to have things like axle spacing washers fitted and contacts wired, etc. So here's a couple of photos of it taken a bit closer to the interesting bits. The crank axle (as covered elsewhere!) uses Laurie Griffin components and is fitted to the axle using Loctite 638 and a couple of brass wire pins. Having proved it fits I'll now keep it out of the chassis until much later in the build - I want to know the basic 0-6-0 chassis runs well before worrying about the valvegear:

The gearbox is one I've had in stock, made up for a while. It pre-dates the current Roxey equivalent; I like asymmetric gearboxes as they make the construction of the split axles so much easier. In the case of this loco the 'main' split in the axle is underneath the white styrene spacer and there's another stealthy one on the outside of the gearbox that was added much later. If it's of interest I can show how these are done? I make them up on the bench: no machine tools necessary (despite what everyone will tell you):

Here's a quick shot of the wheels and hornblocks out of the frames. The driven- and leading-wheelsets both use Slater's 7961 (IIRC) described as an 'insulated square bearing'. It's made from glass filled nylon (as their wheels) and has a brass (or maybe copper?) bearing insert in the middle. These haven't been wired for pickup yet, it's a job I'll be doing soon. On the leading wheelset (at the back of the picture) you can see that I've drilled a 'pit' in the top of the hornblock to take a screw and spring to give some height/level adjustment at the front of the chassis; you'll also note the mark on the axle; it's the epoxy used to insulate the axle. The driven wheelset has been made up with no sideplay in it - the sideplay is given by the hornblocks moving in the hornguides. The crank axle isn't electrically split, I've got round this by not running wires down the backs of the wheels from the rim to the hub, which is what the others have. This axle will need a couple of axle spacing washers fitted between the hornblocks and the wheels for two reasons: 1) sideplay on the crank axle may cause problems with con-rod clearances and 2) I want the backs of the wheels to be used as the 'limiter' on sideplay, rather than the crank axle as I think the wheels are probably better able to take the sidethrusts than it going the whole way through the axle.

The last few photos show the compensation beams and hornblocks. The compensation beam is much more artistically shaped than I would usually make it. It started off as a very simple shape but by the time I'd finished thinking about it the shape became much more subtle around the crank axle and I think it'll end up looking like part of the hornguide rather than obviously a compensation beam. The extra set of holes are in there to clear a brake hanger bracket in case I need to wire or thread the holes to attach the brakegear (I haven't decided yet). The rear set of hornguides are simply made from some good quality milled 3mm x 3mm 'L' section brass. You may also notice the brake lever set: this is new and was made up on the spacer with 224 solder before the chassis was assembled. It a 'nice to have' which isn't in the kit...

And here's a couple of shots showing how I managed to modify a set of Martin Finney hornguides to take the Slater's insulated bearings. An assembled, but otherwise unchanged, hornblock/guide is shown for comparison. So there's a set of nice detailed hornblocks that are also handy for split axles. Insulating at the bearing means that the frames and brakegear can all be assembled pretty much normally, but with split axles you get low maintenance, low friction pick-up. Useful when this model will be putting in many miles on a layout that's probably the best part of fifty miles from here!

Well, that's it from me for the moment. Updates will occur as I progress...

Steph

Well, the title to this thread is a phrase I never imagined I'd be putting together. In fact putting my name in any proximity to anything WR would have caused a fairly extreme reaction until fairly recently. Two things have changed this and I now have a few WR locos in the 'to do' pile: a 'Duke', an 'Earl' (note, I didn't say 'Dukedog', so I'm learning!) and this 2251...

The two changes? Well, modelling the Romsey-Southampton stretch of the Southern requires a small number of WR locos to work the inter-regional trains and the second thing is reading 'Locomotive Adventure' by Harry Holcroft. A 43xx may well follow after I realised Holcroft's involvement.

So with another thread on making up the inside valvegear up and running, this thread is much more about the constructional bits and pieces, the updates, trials, tribulations and general ego-trip that these things tend to be. So here's where I got up to, about half an hour ago after some months of fiddling, research, etc. and a couple of evenings actually at the bench:

It's now got to come apart to have things like axle spacing washers fitted and contacts wired, etc. So here's a couple of photos of it taken a bit closer to the interesting bits. The crank axle (as covered elsewhere!) uses Laurie Griffin components and is fitted to the axle using Loctite 638 and a couple of brass wire pins. Having proved it fits I'll now keep it out of the chassis until much later in the build - I want to know the basic 0-6-0 chassis runs well before worrying about the valvegear:

The gearbox is one I've had in stock, made up for a while. It pre-dates the current Roxey equivalent; I like asymmetric gearboxes as they make the construction of the split axles so much easier. In the case of this loco the 'main' split in the axle is underneath the white styrene spacer and there's another stealthy one on the outside of the gearbox that was added much later. If it's of interest I can show how these are done? I make them up on the bench: no machine tools necessary (despite what everyone will tell you):

Here's a quick shot of the wheels and hornblocks out of the frames. The driven- and leading-wheelsets both use Slater's 7961 (IIRC) described as an 'insulated square bearing'. It's made from glass filled nylon (as their wheels) and has a brass (or maybe copper?) bearing insert in the middle. These haven't been wired for pickup yet, it's a job I'll be doing soon. On the leading wheelset (at the back of the picture) you can see that I've drilled a 'pit' in the top of the hornblock to take a screw and spring to give some height/level adjustment at the front of the chassis; you'll also note the mark on the axle; it's the epoxy used to insulate the axle. The driven wheelset has been made up with no sideplay in it - the sideplay is given by the hornblocks moving in the hornguides. The crank axle isn't electrically split, I've got round this by not running wires down the backs of the wheels from the rim to the hub, which is what the others have. This axle will need a couple of axle spacing washers fitted between the hornblocks and the wheels for two reasons: 1) sideplay on the crank axle may cause problems with con-rod clearances and 2) I want the backs of the wheels to be used as the 'limiter' on sideplay, rather than the crank axle as I think the wheels are probably better able to take the sidethrusts than it going the whole way through the axle.

The last few photos show the compensation beams and hornblocks. The compensation beam is much more artistically shaped than I would usually make it. It started off as a very simple shape but by the time I'd finished thinking about it the shape became much more subtle around the crank axle and I think it'll end up looking like part of the hornguide rather than obviously a compensation beam. The extra set of holes are in there to clear a brake hanger bracket in case I need to wire or thread the holes to attach the brakegear (I haven't decided yet). The rear set of hornguides are simply made from some good quality milled 3mm x 3mm 'L' section brass. You may also notice the brake lever set: this is new and was made up on the spacer with 224 solder before the chassis was assembled. It a 'nice to have' which isn't in the kit...

And here's a couple of shots showing how I managed to modify a set of Martin Finney hornguides to take the Slater's insulated bearings. An assembled, but otherwise unchanged, hornblock/guide is shown for comparison. So there's a set of nice detailed hornblocks that are also handy for split axles. Insulating at the bearing means that the frames and brakegear can all be assembled pretty much normally, but with split axles you get low maintenance, low friction pick-up. Useful when this model will be putting in many miles on a layout that's probably the best part of fifty miles from here!

Well, that's it from me for the moment. Updates will occur as I progress...

Steph

Last edited: