Dikitriki

Flying Squad

Hi,

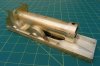

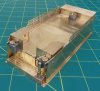

I've got the basic chassis together. It all fitted very well, the biggest part of the time spent was in carefully decusping the components.

It's set up so that the drivers are beam compensated either side with the bogie pivot being the 3rd part. Again, that took some time to set up just so, filing the arms back on the beams where they rest on the hornblocks.

I've also done the basic work on the cylinders.

and I am making the leading springs screw in so that I can drop the front axle with the inside valve gear.

The supports will take a tap for 12BA.

Richard

I've got the basic chassis together. It all fitted very well, the biggest part of the time spent was in carefully decusping the components.

It's set up so that the drivers are beam compensated either side with the bogie pivot being the 3rd part. Again, that took some time to set up just so, filing the arms back on the beams where they rest on the hornblocks.

I've also done the basic work on the cylinders.

and I am making the leading springs screw in so that I can drop the front axle with the inside valve gear.

The supports will take a tap for 12BA.

Richard