Things are coming together nicely but up to yesterday there wasn't much to show.

First I folded down the inside section of the top half on the sides and soldered it in place to and bottom.

Then I drilled out all the holes for the door handles, bump stops etc.

Next was the task that many dread, creating the tumble home or turn under. My method for doing this makes it quite simple (or I think so).

I get a strip of 2" masking tape a bit longer than the coach side and stick it to the outside of the coach, level with the bottom of the windows. I have a length of 28mm diameter tube that is about 18" long (a left over from fitting a curtain rail).

I placed the coach side outside face down on the sheet of plate glass that covers most of my work bench top with the remainder of the sticky side of the masking tape facing upwards.

Next I placed the tube on the sticky tape adjacent to the bottom edge of the coach side. I wrapped the rest of the tape around the tube.

Then grasp the tube at each end where there was no tape I rolled the tube towards the centre of the coach gently but firmly. The masking tape pulls the coach edge around the tube and the tumblehome is formed.

On the first side I went a little too far and had to bring some of the curve back out by laying the back of the side on the glass and gently pressing along it. The second side came out perfectly first time. If there is interest in the method I will do a step by step as I do the next one.

Next I soldered in the bump stops. These are not provided in the kit - the instructions suggest that you solder in 0.45mm wire. These are I believe from Laurie Griffin but I got them in with a lot of other spares and I think that I have enough to do another couple of coaches after this one. I have made them from scrap etch and rod before but to be honest having seen how nice these are I will buy some more in the future when I need them.

The T handles are very nicely cast and are included in the kit. There are also some nicely etched grab handles that I was a bit dubious about initially - initially went to the trouble of soldering a piece of 0.5mm wire to the back of one to beef it up but it was the very devil to bend. So I went back to trying the etch as supplied and they are more substantial than I first guessed. What I do like about this kit is that there are loads of spares of a lot of the pieces. So far I have spare T handles/grab handles/hinges and drop lights.

The hinges are a really nice touch, they come as three fingers that go through the coach side which once you have soldered them solid there is a half etched line which allows them to be snapped off leaving behind differing hinges for the various points on the coach side - some care is needed to get them all the right way up before soldering them in. The etched slits for these needed opening out a little with a .5mm drill.

Once all these were in place you need to snip off the ends that protrude inside and clean/file back so that the drop lights can be fitted. I did this with a diamond coated ball bit in my Dremell.

Next up is fitting the drop lights and then the cornice strip. The cornice strips are handed so once again double check to make that you have the right one with the rain strips above the doors.

Once all this was done I gave everything a good clean up and made sure that all the stubs on the inside face were ground/filed off (I had missed a few earlier).

I had decided that on this coach I would represent the end windows as having been filled in with a solid panel – blanks are provided for this so I bent them to shape and soldered them in before starting to add the sides

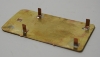

Then came soldering the first side on, I started with the compartment side – this being the one that the tumble home had gone perfectly. I initially sat the floor pan on my sheet of glass and placed the side up to it. When I was satisfied that it was all sat level, I tacked the top of the bulkheads leaving the ends free. Once I was happy that it was all going into position where it should I tacked the bottoms of the bulkheads, then I worked my way down the sides of the bulkheads and across the bottom seams finally ding the ends last.

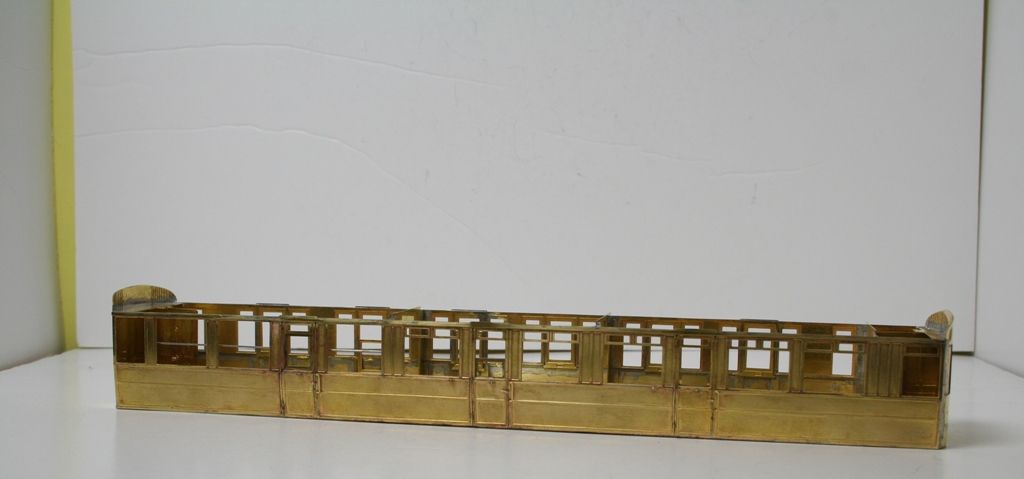

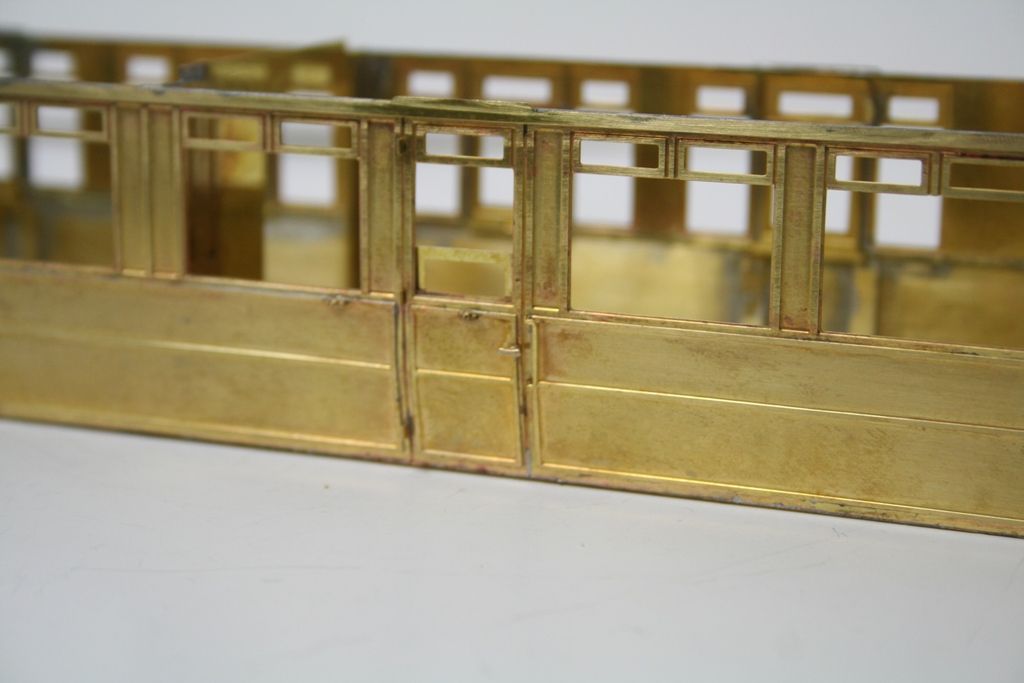

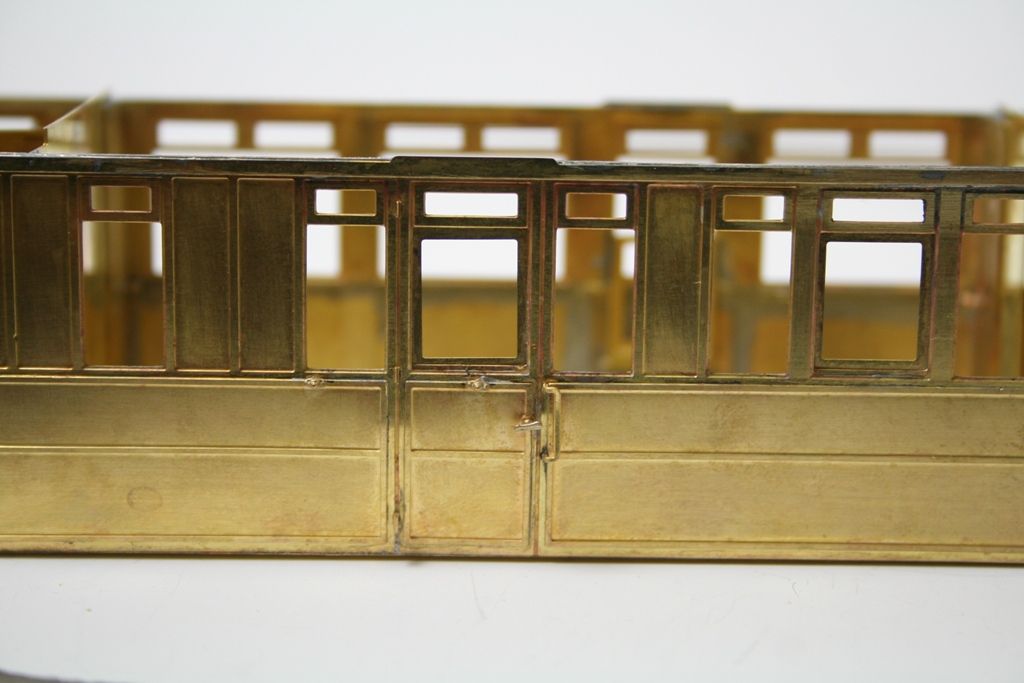

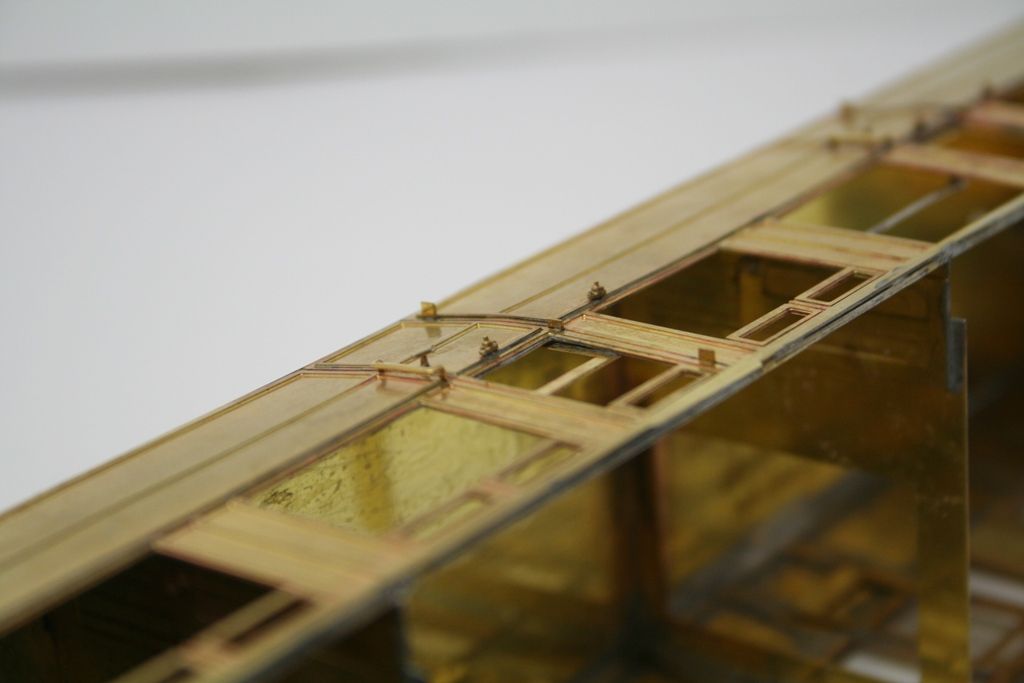

Here are a few shots of what it looks like at this point.

I couldn’t resist a glimpse through the window….

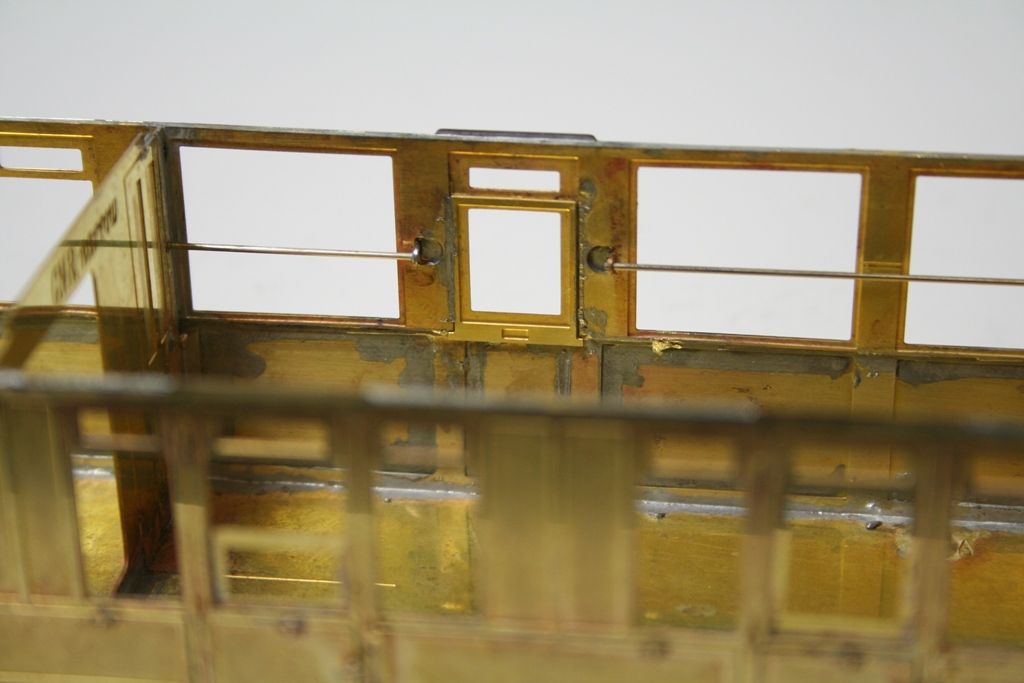

A couple of shots of the drop lights and the “chrome” handrail – this wasn’t supplied I just reasoned that nickel would represent the handrail better and I have just restocked various sizes.

Looking forward to seeing the pictures when your IT is back up and running,

Looking forward to seeing the pictures when your IT is back up and running,