Arty

Western Thunderer

Here are a few notes based on my experiences of making a number of RSUs over the years, it's not a "how to" more of a "what's inside"

It looks like a London Rd Models unit but it's not. There's very little inside so it would be difficult to make it in any other way, the green mushroom on the top is just a duplicate of the footswitch attached. The sockets on the front are to select power output.

Inside is a big isolating transformer, specially wound to provide 3 low voltage output, in this case 1.3v, 2.7v & 4.5v - the black skt is a common return.

As you can see, it's a bit empty ( apart from the transformer ) at the rear is the cable supplying 230v mains via a fuse and the on/off switch, which is a momentary footswitch ie it's only on when you have your foot on it, otherwise the unit is disconnected from the mains. Trying to find a switch of a suitable rating for the low voltage/high current side might be difficult.

A better way to connect the probe and return leads to the unit would be to use 6 or 8mm studding fixed to a Tufnol/fibreglass insulating plate and heavy duty eyelets crimped onto the leads. But it does make adjusting the o/p power a bit a bit of a chore.

The leads obviously have to cope with high currents, but only for maybe 2 to 5 seconds, so a continous rating cable is not neccesary. As an example, 2.5mm domestic wiring cable has a continous rating of about 27 amps, but cable is available of the same cross sectional area that has a 50 amp rating here

These cables and other that would be suitable have a high temperature outer insulation, not pvc which will suffer from the inevitable heating effect.

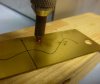

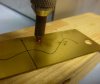

This unit can supply 80-90 amps on a good day but it would certainly blow a thin etch to oblivion ( well blow a hole in it) The key to efficient operation is to have as few connections in the low voltage circuit, the only bit of high resistance we need is the carbon electrode to provide the heat. The carbon rod holder is made from a modified X-acto modelling knife with a PTFE sleeve machined to fit.

I always found the best way to attach the return ( or ground ) to the work with a croc clip or soldered direct, bits of steel as a work surface makes a great heat sink, it will also get pretty dirty with flux contamination, so would not be a good connection. I also find I get better results pre-tinning the smaller part with a conventional iron, and making sure you add some more flux when you make the joint proper.

It looks like a London Rd Models unit but it's not. There's very little inside so it would be difficult to make it in any other way, the green mushroom on the top is just a duplicate of the footswitch attached. The sockets on the front are to select power output.

Inside is a big isolating transformer, specially wound to provide 3 low voltage output, in this case 1.3v, 2.7v & 4.5v - the black skt is a common return.

As you can see, it's a bit empty ( apart from the transformer ) at the rear is the cable supplying 230v mains via a fuse and the on/off switch, which is a momentary footswitch ie it's only on when you have your foot on it, otherwise the unit is disconnected from the mains. Trying to find a switch of a suitable rating for the low voltage/high current side might be difficult.

A better way to connect the probe and return leads to the unit would be to use 6 or 8mm studding fixed to a Tufnol/fibreglass insulating plate and heavy duty eyelets crimped onto the leads. But it does make adjusting the o/p power a bit a bit of a chore.

The leads obviously have to cope with high currents, but only for maybe 2 to 5 seconds, so a continous rating cable is not neccesary. As an example, 2.5mm domestic wiring cable has a continous rating of about 27 amps, but cable is available of the same cross sectional area that has a 50 amp rating here

These cables and other that would be suitable have a high temperature outer insulation, not pvc which will suffer from the inevitable heating effect.

This unit can supply 80-90 amps on a good day but it would certainly blow a thin etch to oblivion ( well blow a hole in it) The key to efficient operation is to have as few connections in the low voltage circuit, the only bit of high resistance we need is the carbon electrode to provide the heat. The carbon rod holder is made from a modified X-acto modelling knife with a PTFE sleeve machined to fit.

I always found the best way to attach the return ( or ground ) to the work with a croc clip or soldered direct, bits of steel as a work surface makes a great heat sink, it will also get pretty dirty with flux contamination, so would not be a good connection. I also find I get better results pre-tinning the smaller part with a conventional iron, and making sure you add some more flux when you make the joint proper.