Dog Star

Western Thunderer

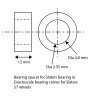

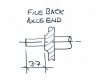

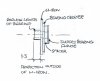

Mick has alluded to another "feature" of using Slater's wheels with Exactoscale underframes and I agree with his approach to (a) adjusting the length of the Slater's axle (no longer need the pin-points and to enable the axles to be inserted / removed without splaying the axleguards too much) and (b) restricting end float (7BA washers, preferably machined washers as stamped versions introduce non-reproducibility).

Ian (@Ian_C), what is the problem or problems that you have encountered?

Ian (@Ian_C), what is the problem or problems that you have encountered?