rosspeacock

Modelling on a £1200 table.

Looks fantastic Simon.. great work..

Ross..

Ross..

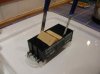

In the sunshine this morning after last night's first pass with the paintbrush.

View attachment 56742

Very nice Simon, but whilst you have the brushes out, being above solebar level, the vertical faces of the concrete end platforms ought to be bauxite too. There may be exceptions of course, but a quick trawl through Paul Bartletts fantastic web site should provide plenty of evidence to support this....

BR Brake van diag 1/504 CAO CAP ZTO ZTQ ZDB ZSR ZTP

Regards

Dan

Hi Simon

What about Northern Fine Scale? They are about to bring out a 1/32 scale BR Brake van and I would have expected transfers to be available for it.

I know you also have a GWR Toad Van and having bought a set of GWR Wagon transfers from Walsall Model Industries at Bakewell this year to try out, even they are supposedly 10mm they are actually closer to 1/32 scale than 10mm, they are blown up from Bill Parker's WEP range.

On their transfer sheet there are 'Park Royal & Old Oak Common, Bordesley Junc and Banbury. If you would like any measurements taken then just ask.

Dave

... Unfortunately this has been achieved at the expense of the ends now being bowed inwards....