adrian

Flying Squad

Wth the glass truck notionally finished (painted and rolling!) I decided to turn my attention to one of my "shelf queens". A quick link for those unfamiliar with Western Thunder tradition of shelf queens.

A Metalmodels etched brass kit for a Siphon F.

It seemed like a good idea at the time but it doesn't really fit into my region of modelling. However I'd just acquired a Resistance Soldering Unit and decided that I'd need an etched brass kit to practice on. Scouring ebay at the time when this popped up, so I put in what I considered to be a lowish bid (about £35-£40 IIRC) as it wasn't something I specifically wanted - I was just after any kit to have a go with. As "luck" would have it I wasn't outbid so it ended up on my workbench!

It's quite an old kit - the instructions are dated 1975 but the etches are clean and crisp. The sides are built up from three layers of etches on the side of the main shell. They use a slot and tab system to locate them as each set of louvres are etched slightly lower than the previous layer. As you build the sides up this gives a very effective 45 degree louvre to the sides.

Unfortunately the whitemetal castings aren't up to the same standard as the etchings or newer kits. The buffers were replaced with brass ones from CPL, I then started building up the bogies, which is the stage that I got to in the first photo and the point at which it got plonked on the shelf to be done later! The castings for the bogie were fairly basic and I lost interest.

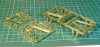

Over the summer I saw a posting about 9' American bogies from JLTRT - so I had a look and decided to get a set. Which is why this has now moved from the shelf to the workbench. So the basic framework has been built up and now got to the stage shown below.

I'm still undecided about the final finish - it's a little too early for my period but it's an interesting vehicle.

A Metalmodels etched brass kit for a Siphon F.

It seemed like a good idea at the time but it doesn't really fit into my region of modelling. However I'd just acquired a Resistance Soldering Unit and decided that I'd need an etched brass kit to practice on. Scouring ebay at the time when this popped up, so I put in what I considered to be a lowish bid (about £35-£40 IIRC) as it wasn't something I specifically wanted - I was just after any kit to have a go with. As "luck" would have it I wasn't outbid so it ended up on my workbench!

It's quite an old kit - the instructions are dated 1975 but the etches are clean and crisp. The sides are built up from three layers of etches on the side of the main shell. They use a slot and tab system to locate them as each set of louvres are etched slightly lower than the previous layer. As you build the sides up this gives a very effective 45 degree louvre to the sides.

Unfortunately the whitemetal castings aren't up to the same standard as the etchings or newer kits. The buffers were replaced with brass ones from CPL, I then started building up the bogies, which is the stage that I got to in the first photo and the point at which it got plonked on the shelf to be done later! The castings for the bogie were fairly basic and I lost interest.

Over the summer I saw a posting about 9' American bogies from JLTRT - so I had a look and decided to get a set. Which is why this has now moved from the shelf to the workbench. So the basic framework has been built up and now got to the stage shown below.

I'm still undecided about the final finish - it's a little too early for my period but it's an interesting vehicle.

). Again with 19 thou brass the A frame needed a little stroking with a rawhide mallet to get a smooth 90 deg fold.

). Again with 19 thou brass the A frame needed a little stroking with a rawhide mallet to get a smooth 90 deg fold.