Tim Watson

Western Thunderer

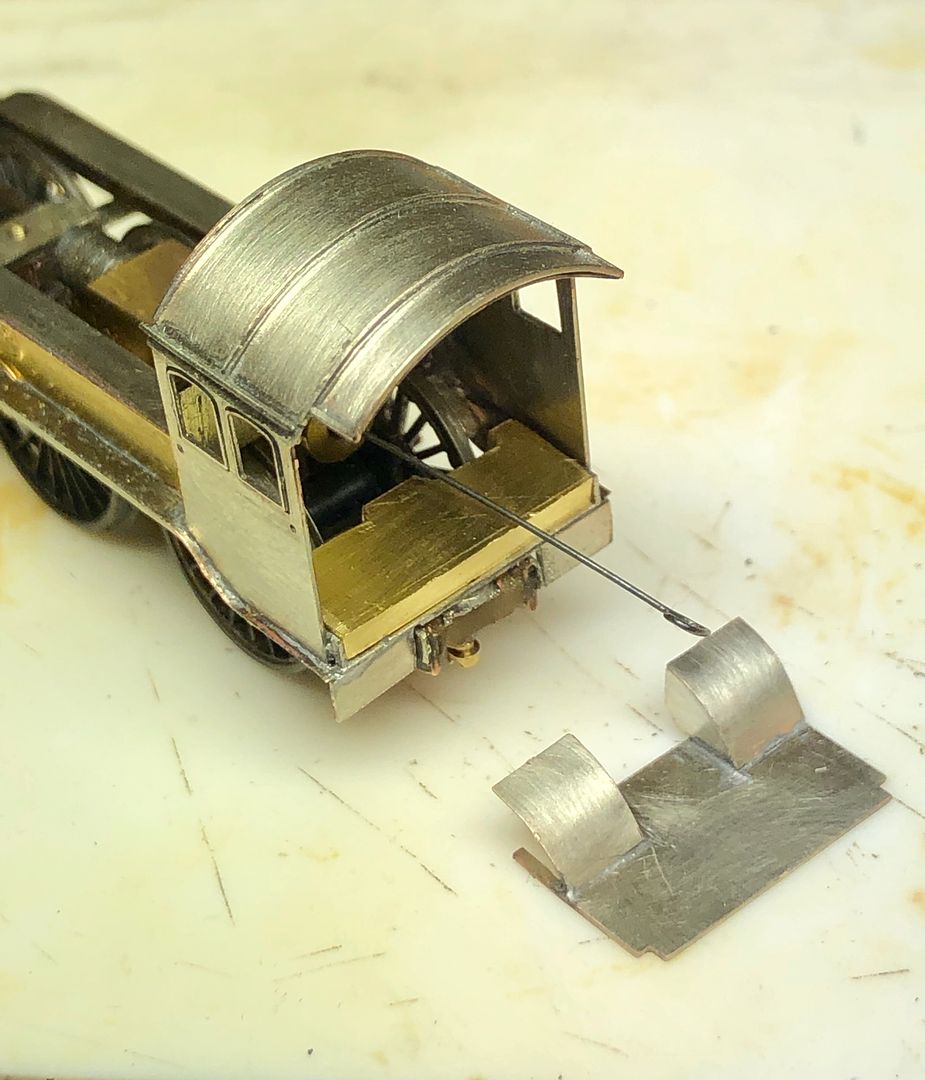

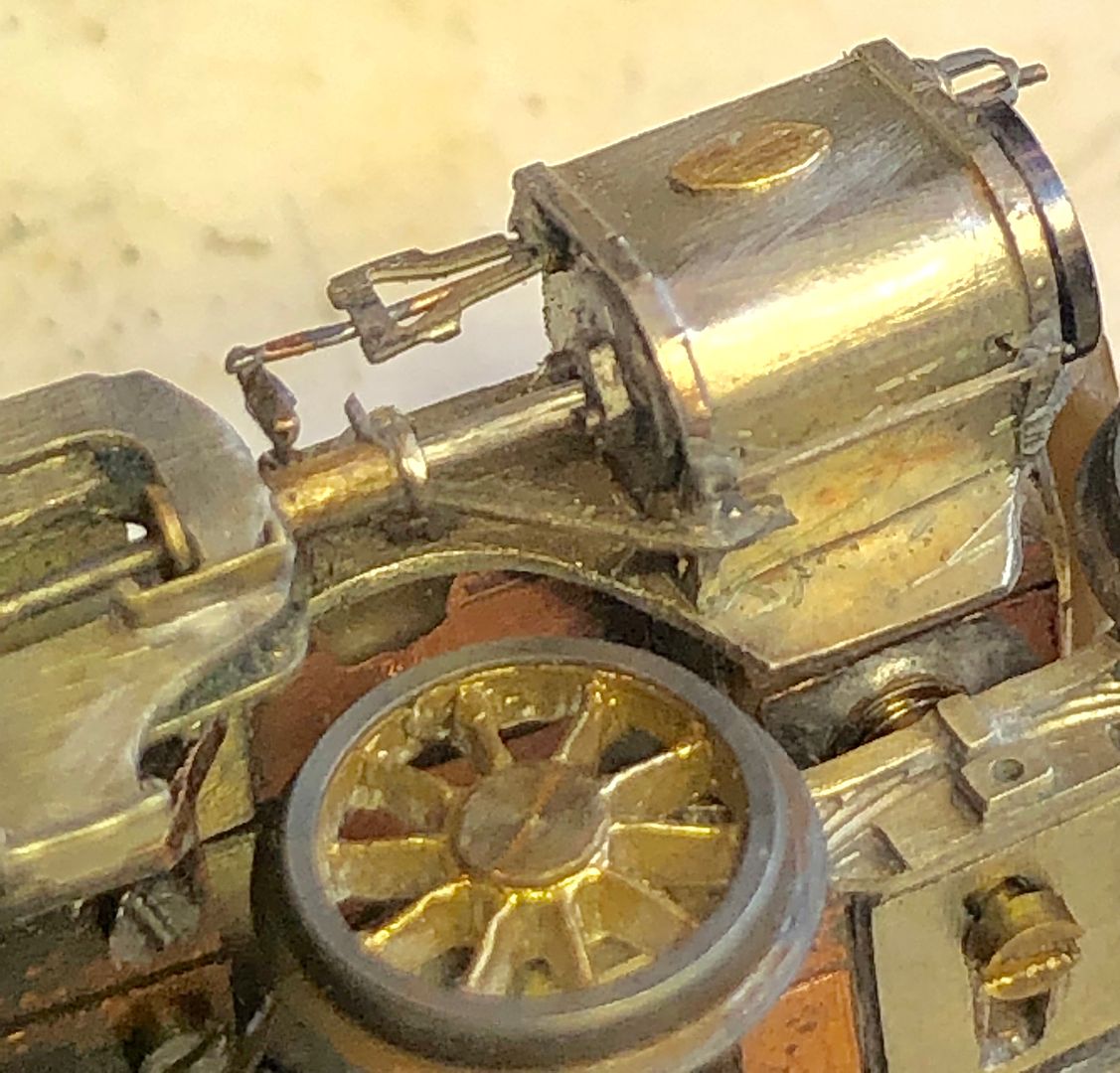

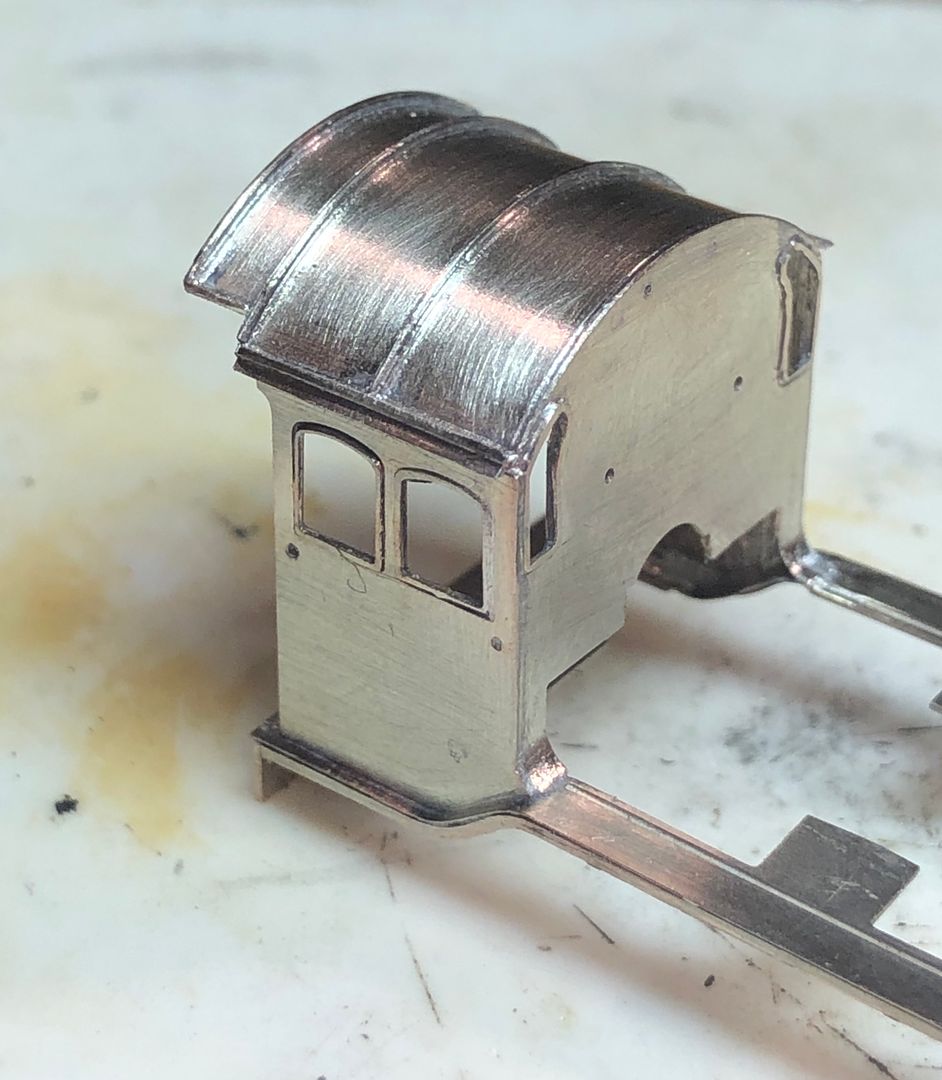

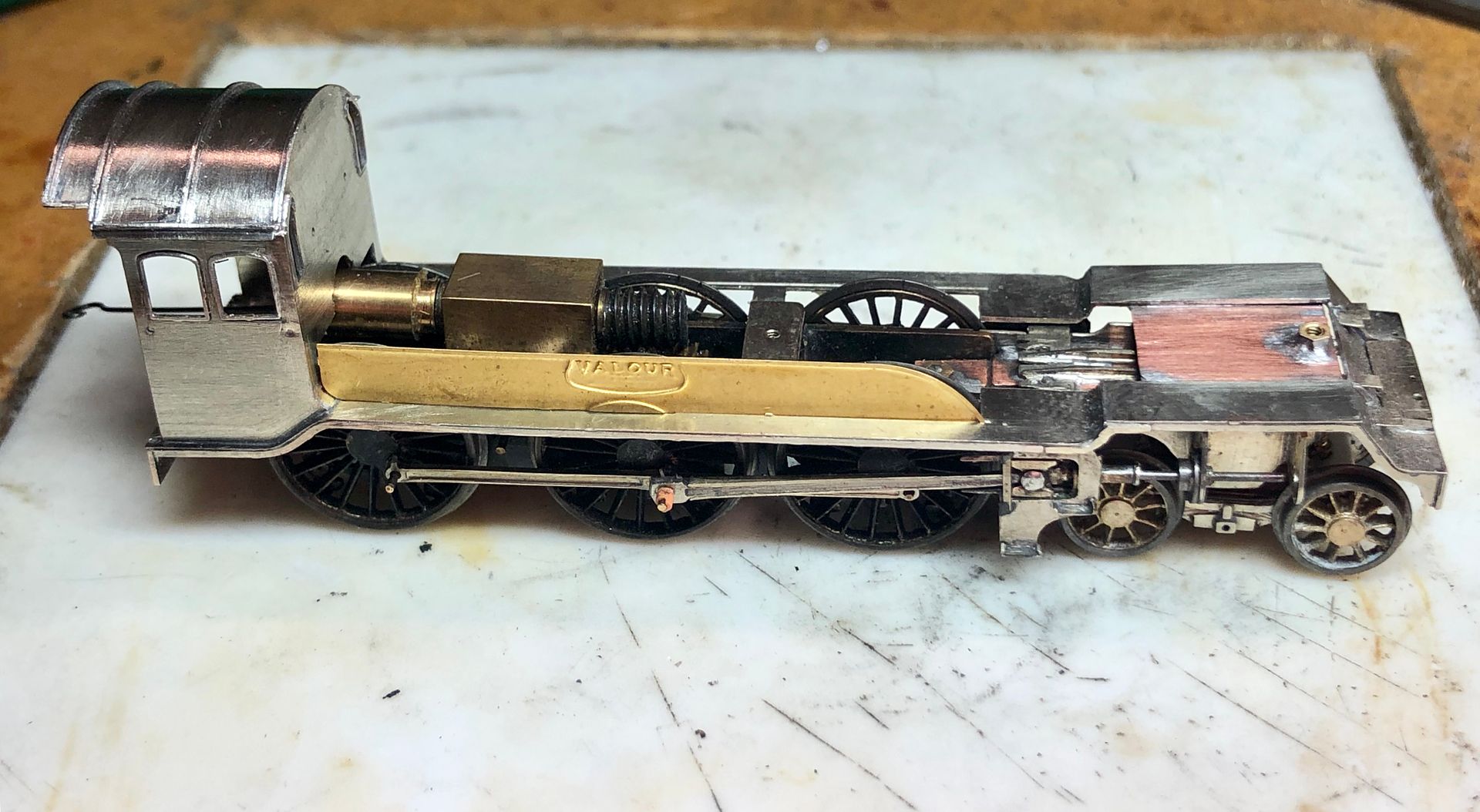

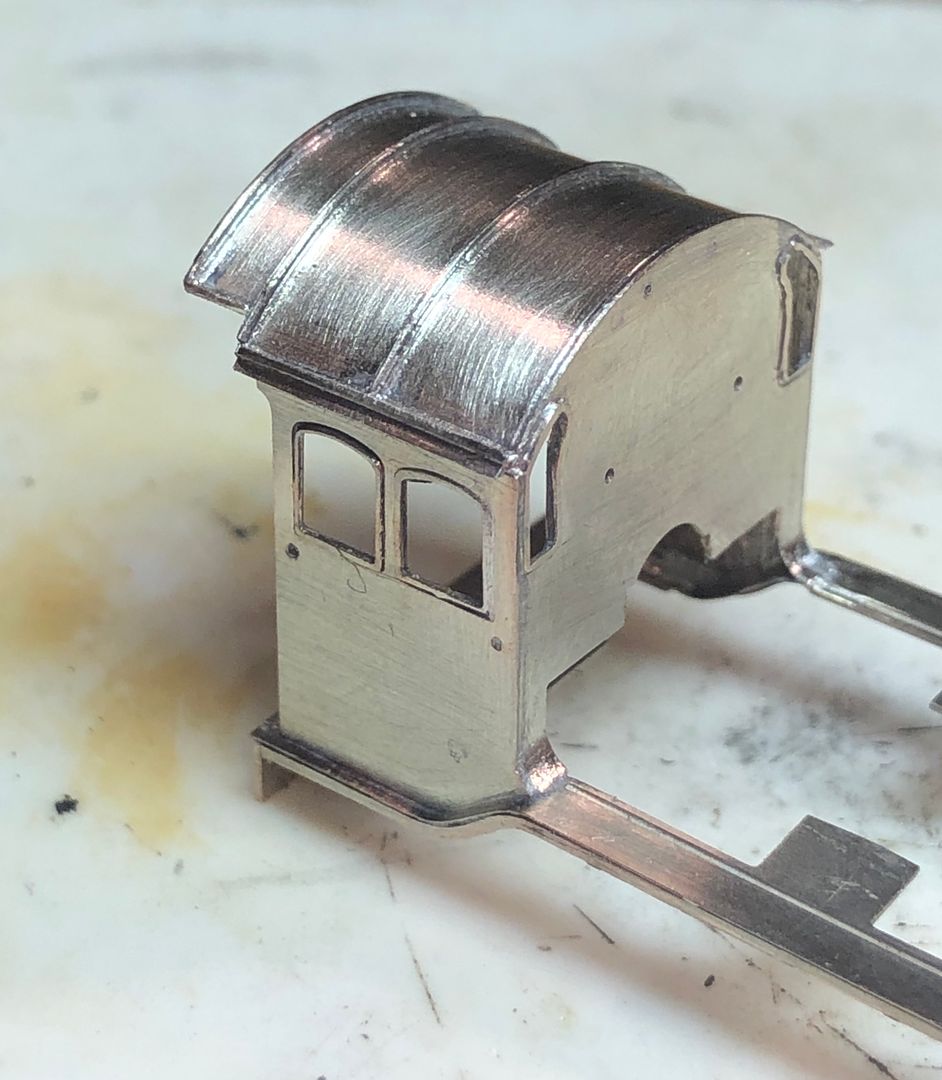

I’ve been working on Valour’s cab over the last couple of days. The windows have etched frames to be fitted - quite fiddly in fact. The front spectacle frames were too fine for use (over-etched for the thickness) and so some strip was bent up and soldered in place. The cab roof has some long slots left proud by half etching in order to accommodate the up right of the characteristic T section external roof ribs. These etched ribs were thinned down with a file to fit the slot and then soldered in place using my trusty surgical clips to hold them in place.

It was easier to solder the back rib in place with it still attached to the etch.

The roof is very rigid with the extra ribs.

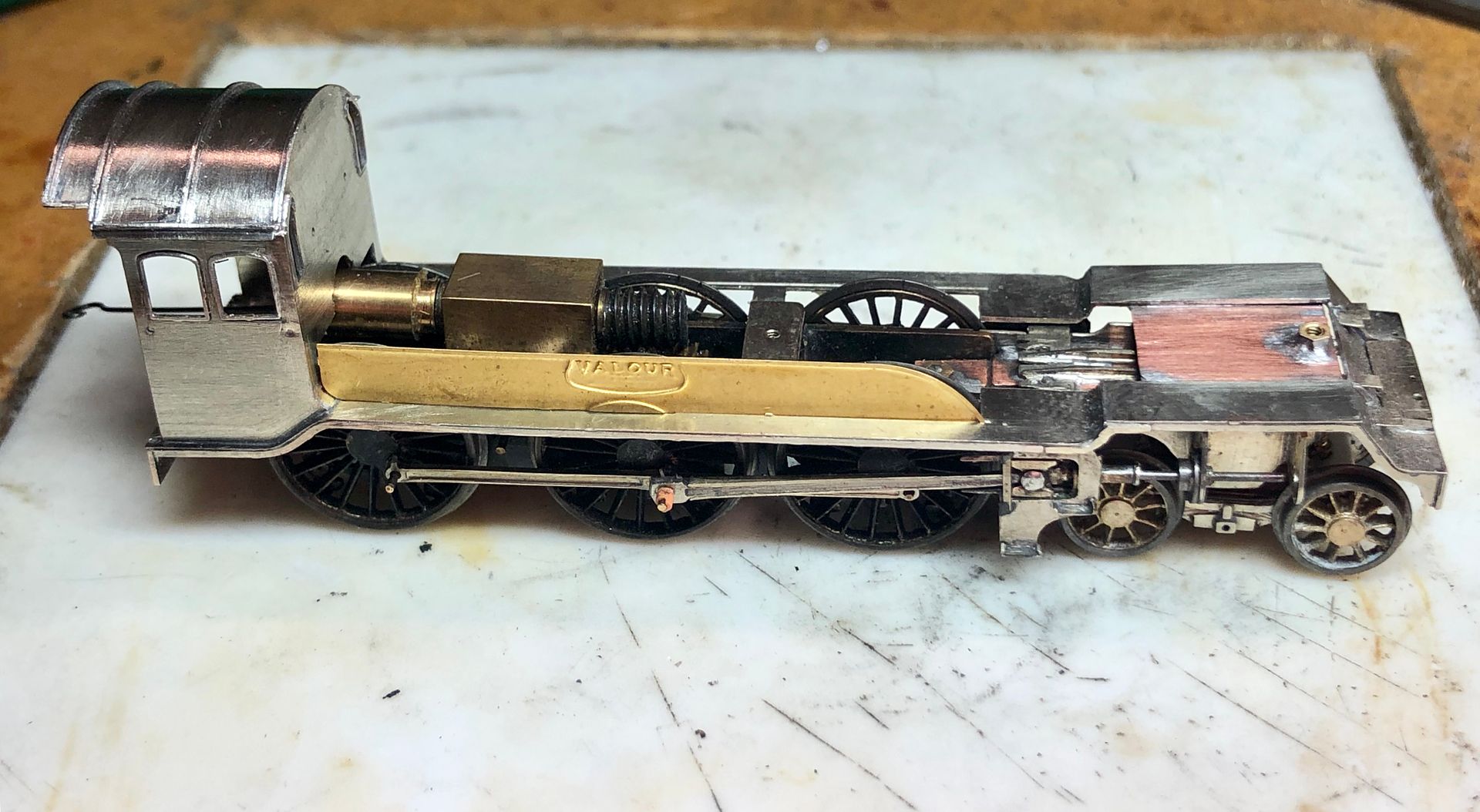

I couldn’t resist putting the splasher with integral nameplate in place. It may, in fact, be the next job.

Tim

It was easier to solder the back rib in place with it still attached to the etch.

The roof is very rigid with the extra ribs.

I couldn’t resist putting the splasher with integral nameplate in place. It may, in fact, be the next job.

Tim

Last edited: