You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

W1 as rebuilt

- Thread starter Dikitriki

- Start date

-

- Tags

- 7mm djh finney7 kit design lner martin finney

Nick Dunhill

Western Thunderer

It'll be ready for release date

Sometime between now and infinity eh?

SimonT

Western Thunderer

Somewhat personal question.Any movement in the body?

mickoo

Western Thunderer

Valve gear squared away, need to replace the reverser lever and lifting arm with the revised one at some point, but the rest all works and fits. On the RH side there's the lubricator linkage to build up so that'll be next.

I've no idea why I placed a round half etch circle on the return crank boss , it should be a square, the product etch will be corrected

, it should be a square, the product etch will be corrected

MD

I've no idea why I placed a round half etch circle on the return crank boss

, it should be a square, the product etch will be corrected

, it should be a square, the product etch will be corrected

MD

mickoo

Western Thunderer

Finally, the last pieces of etch work are done and fitted.

A couple of errors which will be corrected on the production run are the holes in the lubricator arms near the top, should be rivets and the hole in the middle of the return crank needs filling; the original idea being to thread it onto the crank pin which is not required on these engines as they have a large nut to fix too.

It does all wiggle like a wiggly thing. Which is good, as after three days assembling it (and it hadn't), then it'd of all been launched over the garden hedge!

Next step is to clean up all the etch work and run one final production copy off to check it all; as well as build the few pieces that have changed along the way.

By that time we should have some nice castings to go underneath and the instructions can be completed.

MD

A couple of errors which will be corrected on the production run are the holes in the lubricator arms near the top, should be rivets and the hole in the middle of the return crank needs filling; the original idea being to thread it onto the crank pin which is not required on these engines as they have a large nut to fix too.

It does all wiggle like a wiggly thing. Which is good, as after three days assembling it (and it hadn't), then it'd of all been launched over the garden hedge!

Next step is to clean up all the etch work and run one final production copy off to check it all; as well as build the few pieces that have changed along the way.

By that time we should have some nice castings to go underneath and the instructions can be completed.

MD

Yorkshire Dave

Western Thunderer

then it'd of all been launched over the garden hedge

It'd been in good company with the amount I've launched into low earth orbit to join the other space junk

.

.mickoo

Western Thunderer

There have been a couple of times where it's been packed up and put in the loft out of harms way!It'd been in good company with the amount I've launched into low earth orbit to join the other space junk.

The next one is a much simpler engine to model, other than the fact there's hundreds of them and thus bound to be a myriad of variants to consider

But first, a few weeks R&R on a personal project.

MD

john lewsey

Western Thunderer

Superb work Mick

Brian McKenzie

Western Thunderer

Lovely work! Did these lubricators supply oil to axleboxes and motion? I imagine a hydrostatic displacement lubricator fed steam oil to the cylinders - but I really don't know. (Would make a great future task  ).

).

-Brian

).

).-Brian

mickoo

Western Thunderer

Brian,

As far as I can see, slide bars and axle box guides are fed from gravity pots mounted to the splashers inside the casing.

The 12 displacement lines go to different areas, at least eight head up front and I suspect go to the stuffing glands on the piston and valve stems, two cross the frames to the drivers side, one forward and one rearward, the remaining two stay on the firemans side and head toward the rear, well that's on the A4 and the W1 isn't much different I suspect.

Just realised I now need to add the valance on this side and the little fence around the lubricators on the footplate.

MD

As far as I can see, slide bars and axle box guides are fed from gravity pots mounted to the splashers inside the casing.

The 12 displacement lines go to different areas, at least eight head up front and I suspect go to the stuffing glands on the piston and valve stems, two cross the frames to the drivers side, one forward and one rearward, the remaining two stay on the firemans side and head toward the rear, well that's on the A4 and the W1 isn't much different I suspect.

Just realised I now need to add the valance on this side and the little fence around the lubricators on the footplate.

MD

mickoo

Western Thunderer

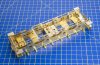

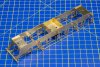

Moving on a little and not the engine, but the tender.

I need one for the W1 show model and it'd be nice to have some photos for the revamped instructions, it's also a nice fill in job until the B1 test etches get here hopefully at the weekend.

It's mostly etch work at the moment and nothing overly exciting. I've opted for a straight out of the build box (nearly) so compensation beams are the order of the day.

The beams and shafts are all done, then realized I'd run out of 5/32" tube, it's on it's way as are the wheels as I hadn't planned to start this for a few weeks (bit of an impulse project as a short break from the F9).

In addition, the tender is being built from stock as it comes in ready for re-release, not from a completed box; so there will be gaps here and there in castings and sundries during the build I'm afraid.

I don't normally like working in brass, it tarnishes readily and solder sometimes just refuses to flow no matter how clean the work, and it's a devil to clean off and shows on photos badly

But, when clean and fresh from the wash it does look nice.

No prizes for the first person that spots C't'ain cock up and his merry crews appearance, I've only just noticed it when uploading the photos, it's not hard to change so will be tomorrows first task.

Because the wheels are not here, nor the 5'32" tube I couldn't fix the brake gear in place, besides I like to have it removable in case I need to get the wheels out in the future.

There's quite a bit of spring in the brake gear so I soldered small pieces of tube to the hanger pins, primarily to keep the hangers equidistant from the chassis and then left the pins slightly over long.

By springing the pins out it is possible to remove the whole brake gear as one assembly.

At the front the etches from the brake shaft at not attached to the brake plank, whose ends need trimming back as yet.

And the two sub components side by side.

I've only put tubes on the front and rear hanger pins, I might need to do the intermediates if it flops about too much and shorts the wheels; next up will be the water scoop linkage and then on to the outer frames and footplate.

MD

I need one for the W1 show model and it'd be nice to have some photos for the revamped instructions, it's also a nice fill in job until the B1 test etches get here hopefully at the weekend.

It's mostly etch work at the moment and nothing overly exciting. I've opted for a straight out of the build box (nearly) so compensation beams are the order of the day.

The beams and shafts are all done, then realized I'd run out of 5/32" tube, it's on it's way as are the wheels as I hadn't planned to start this for a few weeks (bit of an impulse project as a short break from the F9).

In addition, the tender is being built from stock as it comes in ready for re-release, not from a completed box; so there will be gaps here and there in castings and sundries during the build I'm afraid.

I don't normally like working in brass, it tarnishes readily and solder sometimes just refuses to flow no matter how clean the work, and it's a devil to clean off and shows on photos badly

But, when clean and fresh from the wash it does look nice.

No prizes for the first person that spots C't'ain cock up and his merry crews appearance, I've only just noticed it when uploading the photos, it's not hard to change so will be tomorrows first task.

Because the wheels are not here, nor the 5'32" tube I couldn't fix the brake gear in place, besides I like to have it removable in case I need to get the wheels out in the future.

There's quite a bit of spring in the brake gear so I soldered small pieces of tube to the hanger pins, primarily to keep the hangers equidistant from the chassis and then left the pins slightly over long.

By springing the pins out it is possible to remove the whole brake gear as one assembly.

At the front the etches from the brake shaft at not attached to the brake plank, whose ends need trimming back as yet.

And the two sub components side by side.

I've only put tubes on the front and rear hanger pins, I might need to do the intermediates if it flops about too much and shorts the wheels; next up will be the water scoop linkage and then on to the outer frames and footplate.

MD

Last edited:

mickoo

Western Thunderer

They are until you have to fabricate themThose lubricator linkages are magnificent..

JB.

, now I know what the 2mm guys go through

, now I know what the 2mm guys go through

MD.

mickoo

Western Thunderer

mickoo

Western Thunderer

No no, not yet sweetieAnd into the folder. Ta

ST

, these are just rough web shots, I'll do some pucker photo shoot ones for the instructions, depth of field, lighting, contrast etc.

, these are just rough web shots, I'll do some pucker photo shoot ones for the instructions, depth of field, lighting, contrast etc.MD

mickoo

Western Thunderer

Good call, will drop the originals into the folder shortlyI can swop them in later, it allows me get on with the layout.

mickoo

Western Thunderer

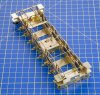

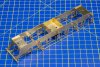

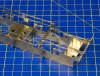

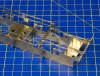

So, sweeping up some bits recently shelved for a short while whilst other work has been completed, back to the W1 tender.

The chassis has finally been completed, I've yet to add the buffers as I'd like to make them retentive, however, being as this'll only ever be a display model I am tempted to just fix the heads in place once it's all painted and used the saved time for something more productive, we'll see.

Underside of the inner chassis, never a fan of equalising beams I was impressed with how well the triple beam system worked.

The final part of the scoop is still missing but the fixing bar is just held in place ready for when the replacement arrives.

Side view of the external frame work.

It's no secret, I have an allergy toward white metal, no matter what I do or which method I follow, they either melt or fall off at the slightest knock. Rather than expend more time, money and ending up with elevated blood pressure and sore throat from all the swearing trying to learn new tricks I simply use an adhesive, in this case Loctite 480. It's not a miracle cure and bonds can fail but overall it tends to work better than my white metal soldering

The two units combined, viewed from below.

There's not a lot of room between the frames and wheels, I've already limited side play with washers so the wheels do not touch the frames but those modeling S7 will need to think about thinning the wheels so that they fit between the frames, there's very little gap on the real things. The reservoir, again three white metal parts, two ends and the barrel didn't fair well, so I binned the barrel and made a brass tube up and soldered the white metal ends on, they for once actually stayed stuck in place

Right side up, rear end.

Front end.

Side profile.

Just a nice smooth rolling chassis really.

I've a few test pieces to make up and fit on the B1 before Doncaster so might get back to this later in the week, it'd be nice to have a basic shell on top for the show but we'll see.

Once the instruction photos are done and Doncaster over with it'll all get primed and sprayed black, keeping brass clean for the rest of the build will be impossible, I learned that the hard way on the Bullied build. Mind this has stayed reasonably clean since I took the last photos 22 days ago but I don't think it'll be many weeks before it tarnishes beyond acceptable levels for photos.

MD

The chassis has finally been completed, I've yet to add the buffers as I'd like to make them retentive, however, being as this'll only ever be a display model I am tempted to just fix the heads in place once it's all painted and used the saved time for something more productive, we'll see.

Underside of the inner chassis, never a fan of equalising beams I was impressed with how well the triple beam system worked.

The final part of the scoop is still missing but the fixing bar is just held in place ready for when the replacement arrives.

Side view of the external frame work.

It's no secret, I have an allergy toward white metal, no matter what I do or which method I follow, they either melt or fall off at the slightest knock. Rather than expend more time, money and ending up with elevated blood pressure and sore throat from all the swearing trying to learn new tricks I simply use an adhesive, in this case Loctite 480. It's not a miracle cure and bonds can fail but overall it tends to work better than my white metal soldering

The two units combined, viewed from below.

There's not a lot of room between the frames and wheels, I've already limited side play with washers so the wheels do not touch the frames but those modeling S7 will need to think about thinning the wheels so that they fit between the frames, there's very little gap on the real things. The reservoir, again three white metal parts, two ends and the barrel didn't fair well, so I binned the barrel and made a brass tube up and soldered the white metal ends on, they for once actually stayed stuck in place

Right side up, rear end.

Front end.

Side profile.

Just a nice smooth rolling chassis really.

I've a few test pieces to make up and fit on the B1 before Doncaster so might get back to this later in the week, it'd be nice to have a basic shell on top for the show but we'll see.

Once the instruction photos are done and Doncaster over with it'll all get primed and sprayed black, keeping brass clean for the rest of the build will be impossible, I learned that the hard way on the Bullied build. Mind this has stayed reasonably clean since I took the last photos 22 days ago but I don't think it'll be many weeks before it tarnishes beyond acceptable levels for photos.

MD