mickoo

Western Thunderer

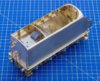

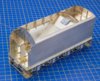

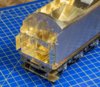

A little more of the tender.

After May 48 the W1 received the streamlined non corridor tender (5639) from A4 60004 which it ran with until withdrawal.

The basic tender is the same but some notes indicate the shovel plate was extended, though those notes are specific to the previous corridor tender they are not specific to the replacement A4 tender as far as I can ascertain.

It's a simply build, follow the yellow brick road and a couple if days later a tender body is ready for fitting.

It's not quite finished, beer and some R&R have stopped play for the evening but essentially everything behind the front plate is complete except buffer housings and tank filler, the buffer housings will go on tomorrow, the tank filler when we get the new stock of castings. As such the whole front end is just placed into position so there are a few gaps between bits and pieces.

There's a fall plate to go over the coal opening and the tabs to bent up on the fixings that hold the streamlined casing smoke box door handle, but other than that, everything above the shelf is done, all of the remaining work is the handles and fittings below and door which I cut off by mistake... I haven't extend the shovel plate, the information is in-concise.

I haven't extend the shovel plate, the information is in-concise.

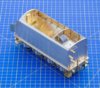

The front end on the A4 and W1 is the high (original) type, if you use this tender on an A3 then there's a lower front end you can fit.

Primarily the lower front end was developed to prevent the slipstream creating a vacuum in the cab, the A4 and W1 have a weather cover, the A3 does not. With the cab roof and tender fairing being the same height (sans weather cover) at high speed the slipstream creates a vacuum and fills the cab with swirling dirt and debris. By lowering the tender front a vortex is formed which destroys the slipstream and thus the vacuum effect. There's many a yarn of A4's being near un-driveable at high speed if the weather cover was damaged.

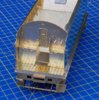

Other than buffer housings and hook the rear end is complete, the lamp irons take a little care and the joint between the two halves will benefit from a bead of paint between them to close the small gap, if you're clever or skilled you could use solder, I'm not or that brave, so paint or dilute PVA works well to seal the seam before painting.

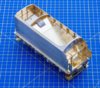

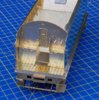

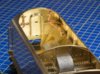

Higher elevation, more the view we're used to, the space for the tank filler being obvious, forgot to add the streamlined faring above the front end needs adding once the front end is in and secure.

Overhead view.

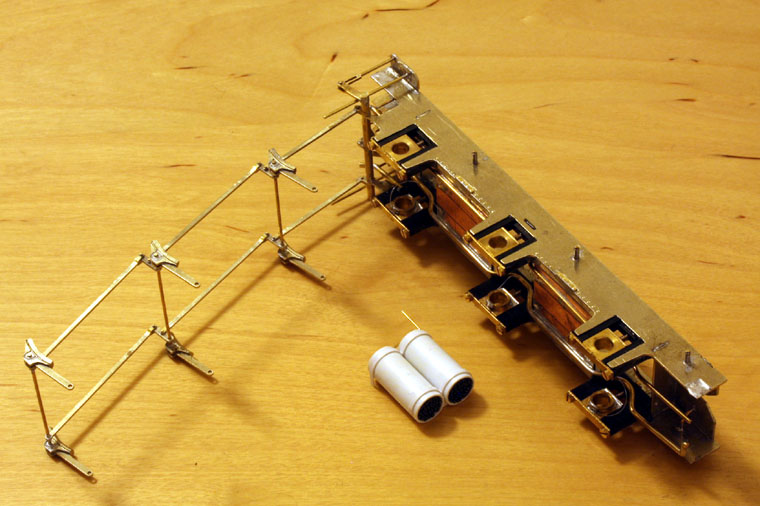

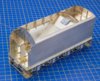

There's still some ugly solder to clean up, a wash in Cillit Bang reveals all your woes

It's smooth enough for painting but for instruction photos, it has to go, annoyingly, this was solder free until the next but last test fit of the coal bunker, a reheat of the joint allowed the solder to weep through to the visual side

There's a few other places that need a scrub and clean, but overall it's just about reasonably presentable for photography.

Enjoy.

MD

After May 48 the W1 received the streamlined non corridor tender (5639) from A4 60004 which it ran with until withdrawal.

The basic tender is the same but some notes indicate the shovel plate was extended, though those notes are specific to the previous corridor tender they are not specific to the replacement A4 tender as far as I can ascertain.

It's a simply build, follow the yellow brick road and a couple if days later a tender body is ready for fitting.

It's not quite finished, beer and some R&R have stopped play for the evening but essentially everything behind the front plate is complete except buffer housings and tank filler, the buffer housings will go on tomorrow, the tank filler when we get the new stock of castings. As such the whole front end is just placed into position so there are a few gaps between bits and pieces.

There's a fall plate to go over the coal opening and the tabs to bent up on the fixings that hold the streamlined casing smoke box door handle, but other than that, everything above the shelf is done, all of the remaining work is the handles and fittings below and door which I cut off by mistake...

I haven't extend the shovel plate, the information is in-concise.

I haven't extend the shovel plate, the information is in-concise.The front end on the A4 and W1 is the high (original) type, if you use this tender on an A3 then there's a lower front end you can fit.

Primarily the lower front end was developed to prevent the slipstream creating a vacuum in the cab, the A4 and W1 have a weather cover, the A3 does not. With the cab roof and tender fairing being the same height (sans weather cover) at high speed the slipstream creates a vacuum and fills the cab with swirling dirt and debris. By lowering the tender front a vortex is formed which destroys the slipstream and thus the vacuum effect. There's many a yarn of A4's being near un-driveable at high speed if the weather cover was damaged.

Other than buffer housings and hook the rear end is complete, the lamp irons take a little care and the joint between the two halves will benefit from a bead of paint between them to close the small gap, if you're clever or skilled you could use solder, I'm not or that brave, so paint or dilute PVA works well to seal the seam before painting.

Higher elevation, more the view we're used to, the space for the tank filler being obvious, forgot to add the streamlined faring above the front end needs adding once the front end is in and secure.

Overhead view.

There's still some ugly solder to clean up, a wash in Cillit Bang reveals all your woes

It's smooth enough for painting but for instruction photos, it has to go, annoyingly, this was solder free until the next but last test fit of the coal bunker, a reheat of the joint allowed the solder to weep through to the visual side

There's a few other places that need a scrub and clean, but overall it's just about reasonably presentable for photography.

Enjoy.

MD

).

).