Peter Cross

Western Thunderer

Fantastic model although not my current scene.

Can't wait to see the next southern kit. Hopefully it's one that I will need.

Can't wait to see the next southern kit. Hopefully it's one that I will need.

Rather depends whether the L11 and T9 are on your shopping list, Peter......

Brian

Too small, need to think biggerOne further along the line I think. K10, a nice little mixed traffic loco. A T9 is would be nice but a bonus.

How about 10000 in its original Yarrow watertube boiler form....... then Mick?

AC 12...

Princess?

Not Southern mate

Len

.

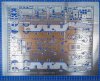

. so bare with the harsh highlights and poor uniformity, but this is what y'all be getting in the box, well, not two sets of motion

so bare with the harsh highlights and poor uniformity, but this is what y'all be getting in the box, well, not two sets of motion

Well there's a reason for that, or at least I think there is, laying everything out in the open can leave you exposed to some criticism that you probably don't want or need occasionally, plus there is a duty to complete, an additional pressure many don't want or need. It does also take quite a lot of time to present the model, photograph and write up as a show and tell.It's been fascinating to follow the development of this kit from start to finish, which is something not seen in the past. A super build Mick and thanks for taking the time to share it all.

Stay safe.

Cheers,

Peter.

CheersThat looks very smart!

JB.

Mick, (@mickoo),No castings in the brake gear, all hand built from etches in the kit.

There may be some mileage in carving out the full monty etched brake gear onto it's own etch, as a stand alone item for those that may wish to dress up older models.

Graham, no this didn't get any further I'm afraid and sadly there are no spares left over from the test builds.Mick, (@mickoo),

What happened to this thought? I ask because we are about to start on the brake gear for an A4 built to run on S7 track and at this point we note that the front and rear brake cross shafts are going to be a source of concern, probably also the brake stretcher beams.

If not a separate etch as describe in your post above, might you have any parts, from the test etches, for the brake shaft levers, the brake stretcher beams / equalising links / pull rods?

regards, Graham