The Eagle has landed

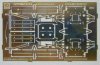

Overall looks good

Couple of faults mind, nothing drastic, one is an own goal, the other a complete mystery.

The own goal is not adding the anti slip pips to one of the rear steps.

It should look like this

They are not very prominent and could do with beefing up but I'll not do a whole new sheet just for these two parts unless there are serious fit errors elsewhere.

The tarnish does not look so bad in real life as I've used an HDR function to sharpen the images and that has accentuated the staining. But they will need a wash with something before starting.

The other Issue is the rear pony pivot stay, it should be solid with a hole in the middle

Okaaayyy it's solid with a half hole, I can live with that, until you turn it over

It's half etched all of the rear and left a pip where the hole should be, I've checked the master art work and it's black both sides, I've checked the B&W art work for printing and it's black both sides and all three have a hole in the middle? This does confirm my worries about the hatching I had, it would seem that the art work is perhaps a little too big or too complex for the hatch fill to work correctly everytime.

I'll send the photos to PPD and ask their thoughts on how it might of happened as for it to be half etched underneath then that would have to be a big blue piece in the master art work or a big white piece on the rear photo tool, it is neither, just pure black both sides

It's not a big deal, i can fabricate a replacement from the spare etch around the work piece and then make a replacement on the cab etch art work.

Finally, the rear half etch frame work needs several bends and working them out would be difficult and impossible to add as a half etch guide line on the rear, perhaps you could do it with the more complex three or four layer system some people use, but for two layers you'll end up with slots.

The front

The rear

As an aid I've added some small triangles half etched on the rear, simply line top and bottom and scribe your guide bend line, better yet, use a skrawker to make a groove and you'll get a nice crisp bend on the other side

Ok time to break out the piercing saw and files

Might be a bit of a handful on 0.45 mm frames mind

Might be a bit of a handful on 0.45 mm frames mind

It's not a big deal, i can fabricate a replacement from the spare etch around the work piece and then make a replacement on the cab etch art work.

It's not a big deal, i can fabricate a replacement from the spare etch around the work piece and then make a replacement on the cab etch art work.