Yorkshire Dave

Western Thunderer

This is an O scale mixed media kit from the Furness Railway Wagon Co. comprising of...

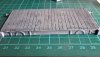

Resin body, whitemetal running gear and brass strapping - not quite an Athearn 'shake the box' kit but nearly.

The items to the left of the brass wire are the kit contents and to the right the additional items - wheels, CPL couplers and a compensation unit. The moulding is reasonable and provides a starting point for me as I intend finishing it in a well used and weather beaten state.

I've already started on the body by bathing it in hot water to soften the resin in order to bow the sides outwards.

In addition to taking the odd lump out of the wood to give it some wear and tear.

Resin body, whitemetal running gear and brass strapping - not quite an Athearn 'shake the box' kit but nearly.

The items to the left of the brass wire are the kit contents and to the right the additional items - wheels, CPL couplers and a compensation unit. The moulding is reasonable and provides a starting point for me as I intend finishing it in a well used and weather beaten state.

I've already started on the body by bathing it in hot water to soften the resin in order to bow the sides outwards.

In addition to taking the odd lump out of the wood to give it some wear and tear.

I hear you cry.

I hear you cry.

. The wagon strapping hasn't been painted yet.

. The wagon strapping hasn't been painted yet.