You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On Michaels workbench - miscellaneous

- Thread starter michael mott

- Start date

michael mott

Western Thunderer

Working on the galley back board now, I find that it is much easier outside of the hull but do need to keep checking for fit. I am amazed at how easy the maple that I cut from the 24 inch diameter log 50 yeas ago planes and has such a rich lustre I guess it is because it has been air dried.

Here is a picture of the center slab that I used to make a coffee table, the rails are ash and the legs Honduras mahogany

The sculpture on the table is ceramic by Tony Bloom.

Michael

Here is a picture of the center slab that I used to make a coffee table, the rails are ash and the legs Honduras mahogany

The sculpture on the table is ceramic by Tony Bloom.

Michael

David Waite

Western Thunderer

Your carpentry skills are exceptional, Absolutely beautiful work, the various shades and the grain of the Maple

Look wonderful and you have managed to match the patterns to compliment each other perfectly.

The air drying of timber certainly changes the structure of the timber over time but Maple is a good timber to work with at anytime, Pacific Maple must be one of my favourite timbers to work with its very soft , unlike the hard Timbers of VIC ash or TAS oak which I love working with where no two pieces behave the same no matter how you dry it, even the grain changes direction in places and it takes the edge off your tool bits extremely quickly.

David.

Look wonderful and you have managed to match the patterns to compliment each other perfectly.

The air drying of timber certainly changes the structure of the timber over time but Maple is a good timber to work with at anytime, Pacific Maple must be one of my favourite timbers to work with its very soft , unlike the hard Timbers of VIC ash or TAS oak which I love working with where no two pieces behave the same no matter how you dry it, even the grain changes direction in places and it takes the edge off your tool bits extremely quickly.

David.

michael mott

Western Thunderer

Jon Nazareth

Western Thunderer

MichaelWell I have flipped into model ship building mode so I will be focusing on my Bristol pilot cutter for a while View attachment 188862

View attachment 188863

View attachment 188864

View attachment 188865

I am trying to finish up the galley and chart table areas next I will be fitting the tap then the gimbal stove.

Michael

I looked at the last posts first and thought that you had made a kitchen sink for your granddaughters dollshouse!

Jon

michael mott

Western Thunderer

Still chipping away at the strips of wood most of the strips are no larger in section than 3x3mm all glued together with lepages yellow fast tack that is diluted 50%.

Today I have to make the main slab to act as the base for finally gluing it together. Also while all the parts are flats I will drill all the holes for the handrails.

A bit of respite in the weather it will get to a balmy -18c today.

Michael

Today I have to make the main slab to act as the base for finally gluing it together. Also while all the parts are flats I will drill all the holes for the handrails.

A bit of respite in the weather it will get to a balmy -18c today.

Michael

michael mott

Western Thunderer

jonte

Western Thunderer

Wonderful stuff, Michael.Obviously I have some more work to do to get everything fitted together properly but I’m pleased with the overall progress and proportions

View attachment 207142

View attachment 207141

View attachment 207140

Michael

Seems a shame to paint it.

Jon

michael mott

Western Thunderer

michael mott

Western Thunderer

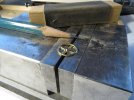

Yesterday and today work was done on the footstep brackets, after deciding on the method of getting a strong support the strips of brass were cut and bent ready to be soldered together. Then using the third hand held for soldering.

I used a small tip on the soldering iron and held it on the underside of the closest corner with a tiny sliver of solder set in the corner the key was holding the iron steady until the sliver flashed and capillaried along the joint.

After cleaning them up they were drilled for the retaining rivets, blackened and glued to the frame.

A test fit of some planks to check for contact at each bracket. Looks good now tomorrow I will add the other side and then drill the holes through the frame and add the rivets to add some mechanical strength to the brackets.

Michael

I used a small tip on the soldering iron and held it on the underside of the closest corner with a tiny sliver of solder set in the corner the key was holding the iron steady until the sliver flashed and capillaried along the joint.

After cleaning them up they were drilled for the retaining rivets, blackened and glued to the frame.

A test fit of some planks to check for contact at each bracket. Looks good now tomorrow I will add the other side and then drill the holes through the frame and add the rivets to add some mechanical strength to the brackets.

Michael

Tim Watson

Western Thunderer

That third hand doesn’t take prisoners does it?

michael mott

Western Thunderer

Jim what I like most about the design is that I can pop in different styles of clamps and by taking my time with setting up it is easy to replicate clamping for multiple pieces.I do like your third hand. I maybe need to make something similar. Like CNC, an aid to advancing years.

Jim.

Tim you’re right it is versatile, the key is being able to adjust one aspect of direction at a time,and then be able to rotate the whole piece about the center post.

Michael

michael mott

Western Thunderer

michael mott

Western Thunderer

Cleaned up the frame for painting, first a couple of light coats of black primer after a good wash in warm soapy water, then Vallejo 72051 black. The lighting has made it look more grey than black, nice to get it uniform black now I can fit the footboards.

They are made from some very fine grained clear fir.

Michael

They are made from some very fine grained clear fir.

Michael