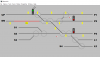

I finally started to lay some track - this is the section from the fiddle yard traverser to the station throat. I did deliberate for some time over what material to use as underlay. In the past, I've always used cork but I was interested to read about the foam that other forum members have tried recently. In the end, I stuck with what I knew - I prefer to pin or screw my track down and was concerned the foam might have got compressed resulting in uneven track. In addition, as my locos are now DCC sound-equipped, noise probably won't be as much of an issue as it has been on previous layouts. I am going to try the Mapei latex solution that SimonD suggested for ballasting, though, rather than diluted PVA.

In case anyone's interested, the lineside cable troughs are the ones that Phil at Intentio laser cut for me. Some of the frets include parts to allow hollow troughs to be constructed so their lids can be left off or skewed as you often see on the prototype. The troughs obviously need to be painted and, once ballasting and landscaping have been completed, I'm guessing you may only see the lids anyway.

Ian

In case anyone's interested, the lineside cable troughs are the ones that Phil at Intentio laser cut for me. Some of the frets include parts to allow hollow troughs to be constructed so their lids can be left off or skewed as you often see on the prototype. The troughs obviously need to be painted and, once ballasting and landscaping have been completed, I'm guessing you may only see the lids anyway.

Ian