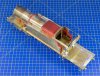

Small update on the WS 72xx, tweaking prints and a splash of colour with a witness layer of paint, it's only an acrylic right now but it'll all have to come off before Warren blatts it with cellulose.

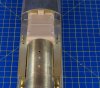

It does show up all the little blemishes which can then be dressed before you find them after final paint. I'm not keen on the previous resin, it's really light and hard to see small blemishes, a new lot of grey arrived today which will make life easier and quicker.

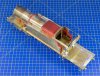

New prints for the tank saddle strap and tool boxes, I offered up the cast backhead and sadly I think it's a generic type and a bit small for this engine, ergo, more printing.

The cab rear is all new to fit my sides, sharp of eye and mind will notice I'm keeping well away from the rear end for the time being, not looking forward to fabricating all that if the truth be told. But it has to be done and I'll take the bull by the horns in due course.