Nick Dunhill

Western Thunderer

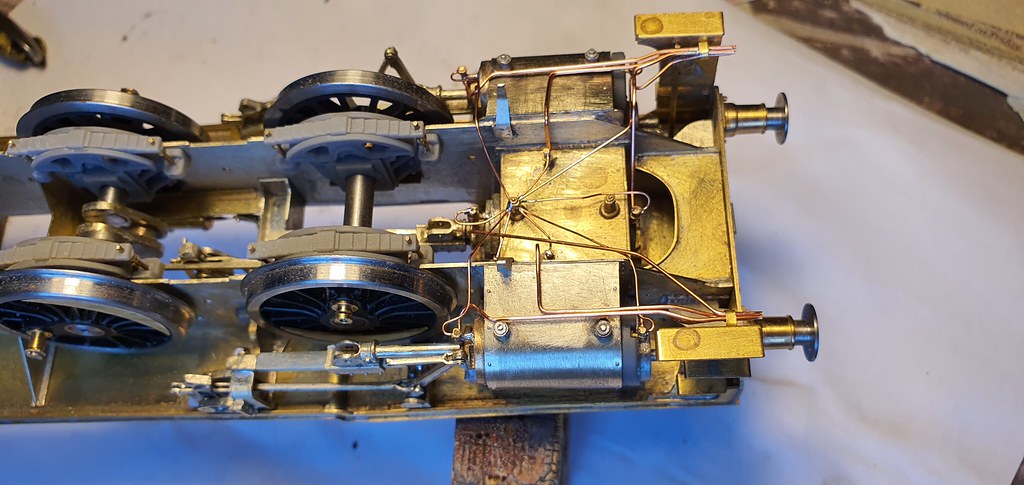

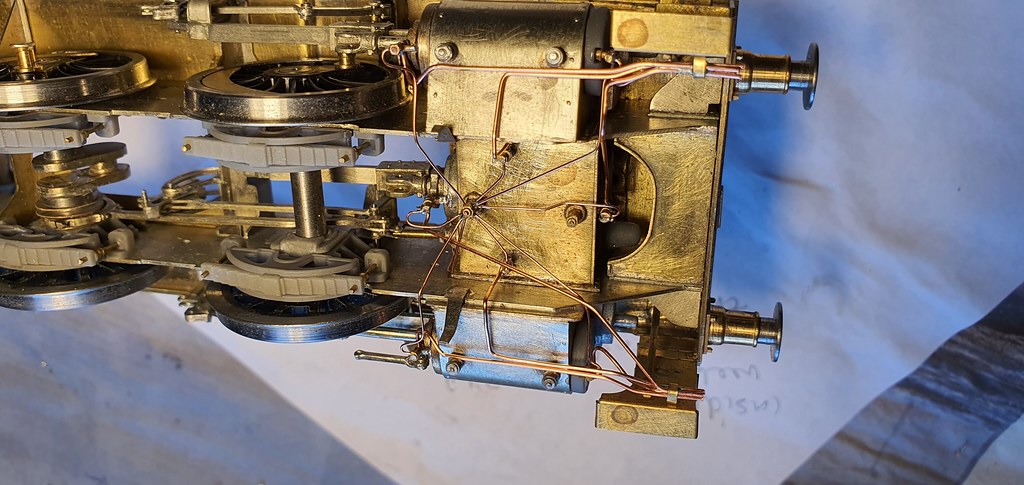

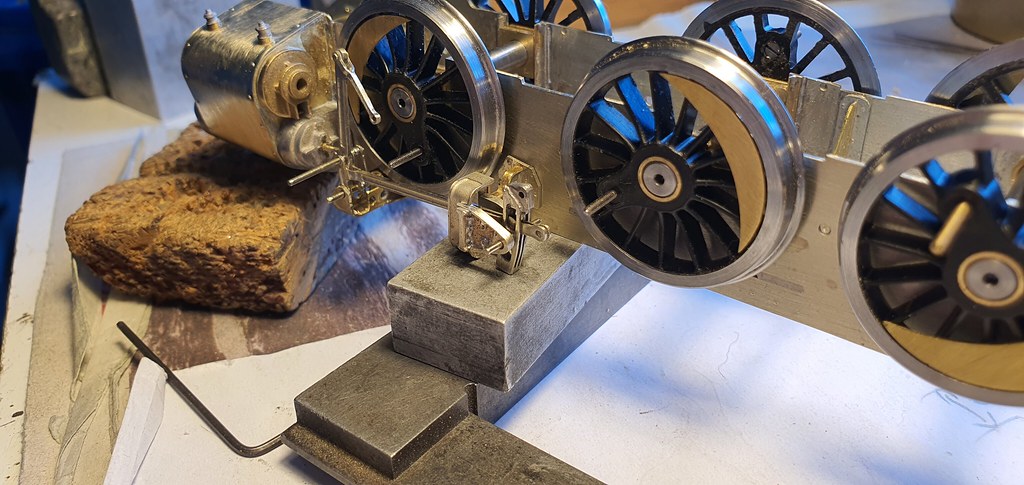

I have moved so far off piste with this build that I realised I would have to fabricate much of it myself. With this in mind I started to compare the drawings I have with the motion parts supplied by DMR. The main motion and valve rod brackets supplied are a very simplified version of the real thing. The expansion link is after the style of Gresley, a 3 bar arrangement with a bifurcated radius rod gripping the centre section. The kit isnt like this, and also the parts for the valve rod swing link don't really fulfil the correct movement. So it was out with the piercing saw! I made all 4 brackets and began laminating the etches supplied, modifying them as I went along.

I began to get a bit exasperated at this point as the two halves of many of the rods did not match, and the hole centres didn't coincide. I had to solder them together and make good as best I could. The etches that fold up into the expansion link were particularly bad. They weren't the same length, the lightening holes were all over the place, the mounting holes weren't in the same plane and they were not symmetrical. I modified them, but in retrospect it would have been quicker to make new ones.

The kit seems to have all the hallmarks of a 4 mm blow up. The simplified valve gear and brackets are probably ok in OO gauge but doesn't really cut it in 7 mm scale. Also all the errors will be exaggerated when enlarged. Anyway I managed to produce something that looks and functions as real loco.

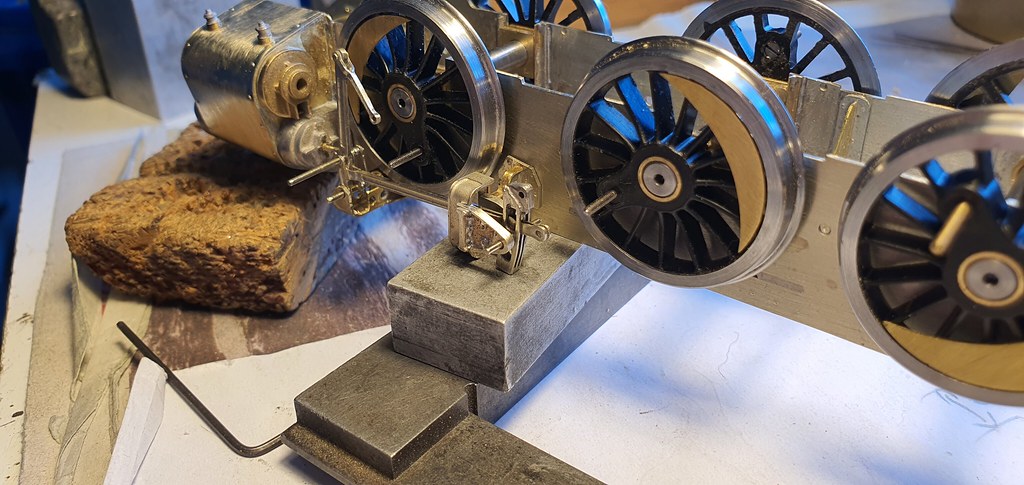

To fit up the motion I needed to fit up the slide bars and crossheads. I had seen on another thread how the etched slide bars provided don't fit the crossheads without a big reduction in size. I reached for some 1.6 mm square bar and gently eased the insides of the slidebar to accept it without loads of slop. I then checked some measurements on the GA and saw that the real slide bars are rectangular and not square. The crosshead also would put the slidebar far too high in the cylinder, ie it's far too tall. More parts to weigh in! I saw that Laurie Griffin has some alternatives in his range that look correct so I placed an order and moved on to the footplate while they turned up.

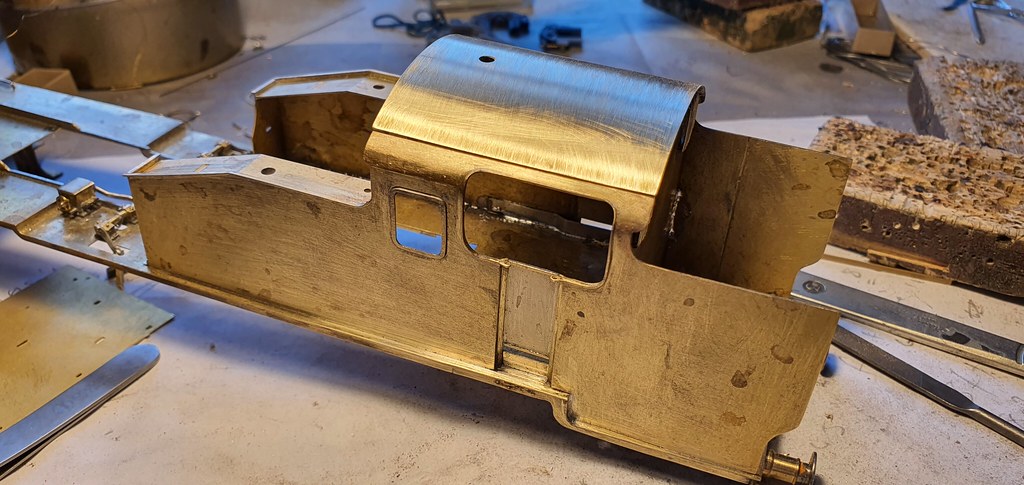

The footplate etch is a one piece affair with relief strips for forming the folds and curves. I began forming it and offering it up to the etched valance. I wasn't surprised to find that they didn't match! I fractured the footplate etch into 3 sections so I could tackle them separately. Also at this stage I offered the valance etch up to the chassis. If the completed footplate was going to land on top of the chassis at the rear and front, and hopefully in the middle, then the valance should be the same shape as the top of the chassis. It wasn't, by a mile! And the completed footplate would end up being too long by about 5 mm. This would also mean that the buffer beams would overhang the ends of the chassis by about 2.5 mm at each end. Also the completed footplate would need to sit on a beer mat placed above the cylinders to make it level.

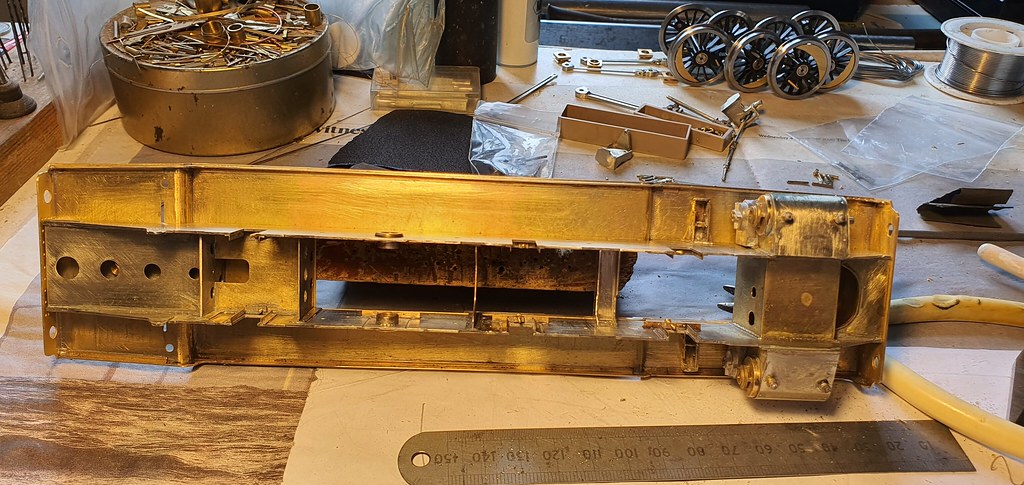

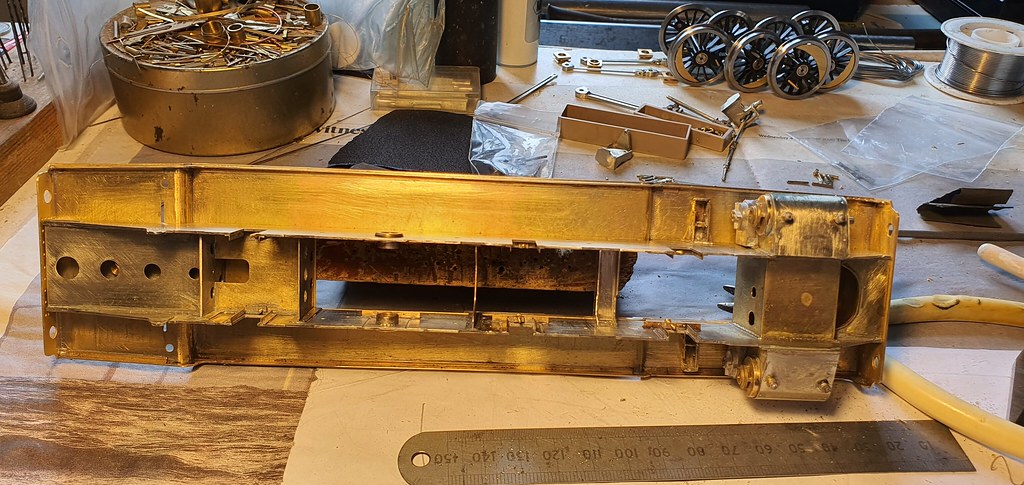

It took a day and a half to make a new footplate but it does now fit the chassis perfectly, and now meets the top of the chassis frames without the usual unsightly gap. I also made the bits of the chassis that stick up above the footplate. The valence is the original etch cut twice to fit. The lower platform, under the bunker, is as supplied as well.

This pic shows all the cut out and formed parts taped to the chassis prior to tacking together.

I'm glad all kits aren't as ill fitting as this, but I have to say that I have enjoyed all the fabrication.

I began to get a bit exasperated at this point as the two halves of many of the rods did not match, and the hole centres didn't coincide. I had to solder them together and make good as best I could. The etches that fold up into the expansion link were particularly bad. They weren't the same length, the lightening holes were all over the place, the mounting holes weren't in the same plane and they were not symmetrical. I modified them, but in retrospect it would have been quicker to make new ones.

The kit seems to have all the hallmarks of a 4 mm blow up. The simplified valve gear and brackets are probably ok in OO gauge but doesn't really cut it in 7 mm scale. Also all the errors will be exaggerated when enlarged. Anyway I managed to produce something that looks and functions as real loco.

To fit up the motion I needed to fit up the slide bars and crossheads. I had seen on another thread how the etched slide bars provided don't fit the crossheads without a big reduction in size. I reached for some 1.6 mm square bar and gently eased the insides of the slidebar to accept it without loads of slop. I then checked some measurements on the GA and saw that the real slide bars are rectangular and not square. The crosshead also would put the slidebar far too high in the cylinder, ie it's far too tall. More parts to weigh in! I saw that Laurie Griffin has some alternatives in his range that look correct so I placed an order and moved on to the footplate while they turned up.

The footplate etch is a one piece affair with relief strips for forming the folds and curves. I began forming it and offering it up to the etched valance. I wasn't surprised to find that they didn't match! I fractured the footplate etch into 3 sections so I could tackle them separately. Also at this stage I offered the valance etch up to the chassis. If the completed footplate was going to land on top of the chassis at the rear and front, and hopefully in the middle, then the valance should be the same shape as the top of the chassis. It wasn't, by a mile! And the completed footplate would end up being too long by about 5 mm. This would also mean that the buffer beams would overhang the ends of the chassis by about 2.5 mm at each end. Also the completed footplate would need to sit on a beer mat placed above the cylinders to make it level.

It took a day and a half to make a new footplate but it does now fit the chassis perfectly, and now meets the top of the chassis frames without the usual unsightly gap. I also made the bits of the chassis that stick up above the footplate. The valence is the original etch cut twice to fit. The lower platform, under the bunker, is as supplied as well.

This pic shows all the cut out and formed parts taped to the chassis prior to tacking together.

I'm glad all kits aren't as ill fitting as this, but I have to say that I have enjoyed all the fabrication.

Last edited: