You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1:12 scale 1966 Ford GT40 , 1931 Alfa Romeo 8C 2300 and 1:18 scale 1967 Ferrari P4

- Thread starter P A D

- Start date

P A D

Western Thunderer

Morning Tony,

No idea what the paint was, but it was very hard and resilient. Abrading with emery paper or steel brush in the mini drill barely touched it and it just laughed at Celly thinners. I left the parts coated in stripper in the ziplock bags for about an hour by which time the paint was bubbling nicely. Celly thinners might have done the same if I'd had enough to soak the parts immersed in a container.

Lots of work to do in removing witness Mark's before re spraying. I believe the metal can be soldered particularly if it's copper plated, as that would be a good way of eliminating the gaps between the upper and lower castings in the front, middle and rear sections. If it can be soldered I can also get rid of the pillars for the screws in the front and rear sections as these are visible through the vents. When it comes to re painting I'll prime it with Halfords etch primer.

I picked this up on Ebay Germany for about 25 quid plus postage which is a very good (and realistic) price for these models. Quality wise, they are at the lower end of the diecast market, but you still see even crap examples them being sold for silly money. I would guess that most of them were bought for toys rather than display, but in recent time the collectors want them. This one was particularly good having (according to the seller) only been used as a display model and not played with, so there were no broken or missing parts and the paint had very few chips. A company called GMP used to do 1:18 scale model but they go for about 300 quid or more. Not that I'd want one as there's not a lot to upgrade on it.

The engine is particularly good.

Cheers,

Peter

No idea what the paint was, but it was very hard and resilient. Abrading with emery paper or steel brush in the mini drill barely touched it and it just laughed at Celly thinners. I left the parts coated in stripper in the ziplock bags for about an hour by which time the paint was bubbling nicely. Celly thinners might have done the same if I'd had enough to soak the parts immersed in a container.

Lots of work to do in removing witness Mark's before re spraying. I believe the metal can be soldered particularly if it's copper plated, as that would be a good way of eliminating the gaps between the upper and lower castings in the front, middle and rear sections. If it can be soldered I can also get rid of the pillars for the screws in the front and rear sections as these are visible through the vents. When it comes to re painting I'll prime it with Halfords etch primer.

I picked this up on Ebay Germany for about 25 quid plus postage which is a very good (and realistic) price for these models. Quality wise, they are at the lower end of the diecast market, but you still see even crap examples them being sold for silly money. I would guess that most of them were bought for toys rather than display, but in recent time the collectors want them. This one was particularly good having (according to the seller) only been used as a display model and not played with, so there were no broken or missing parts and the paint had very few chips. A company called GMP used to do 1:18 scale model but they go for about 300 quid or more. Not that I'd want one as there's not a lot to upgrade on it.

The engine is particularly good.

Cheers,

Peter

P A D

Western Thunderer

Today I made a start on improving the front suspension area. These are the springs I knocked up from styrene tube, rod and copper wire.

The pins at each end located into holes drilled in the wishbone assemblies.

T'other side. That ridiculous steering shaft will also be replaced, so although it will still be far from perfect, this area of the model will look a whole lot better.

With the replacement steering shaft that I will make, I'll loose the link to the steering rod so the steering wheel will no longer rotate when the wheels are moved left or right, but I'm not fussed about that. I will at least then be able to pose the model with the wheels facing left or right, which can't be done as it comes as the steering shaft set up just springs the wheels straight again when they are released.

Cheers,

Peter

The pins at each end located into holes drilled in the wishbone assemblies.

T'other side. That ridiculous steering shaft will also be replaced, so although it will still be far from perfect, this area of the model will look a whole lot better.

With the replacement steering shaft that I will make, I'll loose the link to the steering rod so the steering wheel will no longer rotate when the wheels are moved left or right, but I'm not fussed about that. I will at least then be able to pose the model with the wheels facing left or right, which can't be done as it comes as the steering shaft set up just springs the wheels straight again when they are released.

Cheers,

Peter

P A D

Western Thunderer

I've made further progress with the front suspension/steering today. The original sterring rack has been removed and replaced with something a little more in keeping with the prototype. The new rack is from 1.2mm copper wire and the pivots from 0.8mm brass rod. The original steering "girder" is laid in front for the photo before I dispatched it to the bin!

The wheels may now be posed to the left or right without springing back centrally, although as mentioned earlier the connection to the steering wheel has been lost

The various bits have also been painted and the springs glued in place on the upper wishbones until it is time to permanently attach the whole unit.

And I couldn't resist a little dabble with the wheels on.

From there I've moved on to the radiator and removed the moulded representations of the finned cooling tubes. I'm replacing them with lengths of threaded brass rod and there will be 5 tubes not 4 as on the plastic moulding. I'm using the front part of the plastic radiator suitably modified.

My brother kindly dropped of my Hakko soldering station and I gave it a go soldering some brass rod to the underside of the chassis. At the maximum 480 celcius setting it did the job, but I'm not sure if it would make the solder (145) flow enough to join the big castings at the seams. I'll have to asked him to bring over my SolderPro 120 and give it a go with that (with great care so as not to melt the casting!).

With the upper and lower main castings screwed together I checked that the plastic interior may be inserted through the gap between the A and B pillars. It does, no problem, which means I can join the parts and eliminate the gaps with filler before painting. I still need to check of the windscreen may be inserted after the interior. Note the hole in the base just at the front edge of the door aperture. That's one I've drill to allow me to get at the screw for the door hinge if I glue solder the castings together.

Cheers,

Peter

The wheels may now be posed to the left or right without springing back centrally, although as mentioned earlier the connection to the steering wheel has been lost

The various bits have also been painted and the springs glued in place on the upper wishbones until it is time to permanently attach the whole unit.

And I couldn't resist a little dabble with the wheels on.

From there I've moved on to the radiator and removed the moulded representations of the finned cooling tubes. I'm replacing them with lengths of threaded brass rod and there will be 5 tubes not 4 as on the plastic moulding. I'm using the front part of the plastic radiator suitably modified.

My brother kindly dropped of my Hakko soldering station and I gave it a go soldering some brass rod to the underside of the chassis. At the maximum 480 celcius setting it did the job, but I'm not sure if it would make the solder (145) flow enough to join the big castings at the seams. I'll have to asked him to bring over my SolderPro 120 and give it a go with that (with great care so as not to melt the casting!).

With the upper and lower main castings screwed together I checked that the plastic interior may be inserted through the gap between the A and B pillars. It does, no problem, which means I can join the parts and eliminate the gaps with filler before painting. I still need to check of the windscreen may be inserted after the interior. Note the hole in the base just at the front edge of the door aperture. That's one I've drill to allow me to get at the screw for the door hinge if I glue solder the castings together.

Cheers,

Peter

Overseer

Western Thunderer

Sorry, I don't know what the longer term interactions would be. It would probably depend on how complete the copper film is. Milliput would be safe to use and is easy to smooth with water.Duly noted. Thank you sir.

If I copper plate the surfaces first, do you know if that will act as a barrier coat and prevent the degradation? Failing that I'll stick with epoxy and fill the gaps with Isopon.

Many thanks,

Peter

P A D

Western Thunderer

Thanks again.

Its not the filling that's an issue. I was hoping to dispense with the screw pillars inside the front and rear covers as they are visible through the air vents.

Soldering would be the preferred option to join the parts but I'll now consider if epoxy will be up to the job. The main body section will still be screwed and the gaps filled with Isopon.

Cheer,

Peter

Its not the filling that's an issue. I was hoping to dispense with the screw pillars inside the front and rear covers as they are visible through the air vents.

Soldering would be the preferred option to join the parts but I'll now consider if epoxy will be up to the job. The main body section will still be screwed and the gaps filled with Isopon.

Cheer,

Peter

P A D

Western Thunderer

Simon very kindly sent me some lead free solder, but unfortunately I had no success with it. Even at 480 celcius I could not get it to flow and to be honest, although the 145 seemed to adhere better, I doubt if it would have flowed sufficiently. However, the construction of the rear clam is such that there are a lot of contact areas, so jointing with epoxy should give a strong joint and I've removed the screw mountings from both castings. The slitting disc followed by lots of elbow grease with various burrs did the trick.

Further work with a burr on the inside of the grills produced a channel for a length of nickel silver strip to represent the support between the vanes. Not the neatest of work but it will be well hidden.

Here's the rear clam after glueing the two castings together showing the improvement in appearance. It still needs work to hide the joint line.

The holes at the rear on the cross member have also been filled with copper wire. I must have another go with the Nitromors to remove the paint in the grill!

The front clam only has contact between the two castings at the sides, so I'll add a reinforcing strip on the inside to beaf up the joint. On the lower part I used a counter sink in the hand drill to remove the mounting pillar. I'll add a piece of 10 thou plasticard to cover the holes on the inside and fill and smooth on the outside.

At the front of the cockpit casting I'ved added an extension from brass sheet to cover the suspension and filled the superfluous holes with copper wire hammered in place and rubbed smooth.

And added the replacement radiator tubes from some tapped rod, brass strip and copper wire.

Brass mesh added to the radiator front.

At the rear end I've removed some of the cross members to allow the engine to fit after modification.

And I've made a start on improving the engine. The missing lower sides of the engine block have been added from NS sheet with copper wire to represent the ribbing. The air intakes have been drilled to open them up and the small tank on top has had the ribbing and filler cap added. The plastic parts are bloody awful to file and rub down, being slightly flexible it goes very "fibrous" and is a sod to get smooth. The intake is only placed for the photo as more work is required.

The lower half of the gear box and transmission is part of the rear suspension mounting so I can't easily change that. The bottom of the sump was integral with the floor pan, but I've removed it and added to the engine. The floor pan is getting binned and will be replaced.

Here's the engine before I added the ribbing to the lower sides of the block.

Cheers,

Peter

Further work with a burr on the inside of the grills produced a channel for a length of nickel silver strip to represent the support between the vanes. Not the neatest of work but it will be well hidden.

Here's the rear clam after glueing the two castings together showing the improvement in appearance. It still needs work to hide the joint line.

The holes at the rear on the cross member have also been filled with copper wire. I must have another go with the Nitromors to remove the paint in the grill!

The front clam only has contact between the two castings at the sides, so I'll add a reinforcing strip on the inside to beaf up the joint. On the lower part I used a counter sink in the hand drill to remove the mounting pillar. I'll add a piece of 10 thou plasticard to cover the holes on the inside and fill and smooth on the outside.

At the front of the cockpit casting I'ved added an extension from brass sheet to cover the suspension and filled the superfluous holes with copper wire hammered in place and rubbed smooth.

And added the replacement radiator tubes from some tapped rod, brass strip and copper wire.

Brass mesh added to the radiator front.

At the rear end I've removed some of the cross members to allow the engine to fit after modification.

And I've made a start on improving the engine. The missing lower sides of the engine block have been added from NS sheet with copper wire to represent the ribbing. The air intakes have been drilled to open them up and the small tank on top has had the ribbing and filler cap added. The plastic parts are bloody awful to file and rub down, being slightly flexible it goes very "fibrous" and is a sod to get smooth. The intake is only placed for the photo as more work is required.

The lower half of the gear box and transmission is part of the rear suspension mounting so I can't easily change that. The bottom of the sump was integral with the floor pan, but I've removed it and added to the engine. The floor pan is getting binned and will be replaced.

Here's the engine before I added the ribbing to the lower sides of the block.

Cheers,

Peter

Last edited:

P A D

Western Thunderer

I see I left a couple of uncaptioned images in the last post. I've deleted them now and re-attached here.

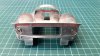

This is the front clam with the original grossly over scale locking clamps, that are only on the rear clam on the prototype.

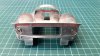

And after replacement with M1 machine screws. In this image the superfluous holes in the cockpit front have yet to be filled with copper rivets as on the clam. Also since this, the rivets have been further smoothed to make flush and I intend to turn down the screw heads in the mini drill and counter sink the holes in the clam to recess them. The holes for the pantograph windscreen wiper will also be plugged as I've got an etched replacement on order and the existing holes are way too large.

On the cockpit front, the clam mounting has been cut back and a hole drilled and tapped M1 for the mounting screw and the superfluous holes filled.

Cheers,

Peter

This is the front clam with the original grossly over scale locking clamps, that are only on the rear clam on the prototype.

And after replacement with M1 machine screws. In this image the superfluous holes in the cockpit front have yet to be filled with copper rivets as on the clam. Also since this, the rivets have been further smoothed to make flush and I intend to turn down the screw heads in the mini drill and counter sink the holes in the clam to recess them. The holes for the pantograph windscreen wiper will also be plugged as I've got an etched replacement on order and the existing holes are way too large.

On the cockpit front, the clam mounting has been cut back and a hole drilled and tapped M1 for the mounting screw and the superfluous holes filled.

Cheers,

Peter

P A D

Western Thunderer

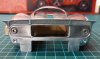

So with the headlight casing super glued to the apertures, I proceeded to epoxy the the top and bottom castings for the front clam. First I made a backing plate for the joints and cut some slots to aid in getting them to sit tight inside the curved faces.

The backing plates were glued into the upper casting and when the epoxy had cured, the tabs were cut down and bent inwards to follow the curve of the lower part. On the lower part I added some brass sheet over the screw holes and ground down the superfluous supports for the headlamp casings. The central support was formed from brass sheet and glued in place.

All done and dusted with the screw holes on the bottom filled with Isopon and rubbed smooth.

It needs a touch of filler here and there, but I'm please with the result.

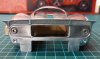

And in place on the body. I've turned down the screw heads and count sunk the holes in the clam. Not perfect but much better than those ugly plastic clamps.

Cheers,

Peter

The backing plates were glued into the upper casting and when the epoxy had cured, the tabs were cut down and bent inwards to follow the curve of the lower part. On the lower part I added some brass sheet over the screw holes and ground down the superfluous supports for the headlamp casings. The central support was formed from brass sheet and glued in place.

All done and dusted with the screw holes on the bottom filled with Isopon and rubbed smooth.

It needs a touch of filler here and there, but I'm please with the result.

And in place on the body. I've turned down the screw heads and count sunk the holes in the clam. Not perfect but much better than those ugly plastic clamps.

Cheers,

Peter

Focalplane

Western Thunderer

Peter

I though you might like to know that a 1929 Alfa Romeo 6c 1750cc supercharged sport will go under the hammer on March 27th

Richard Edmonds Auctions | Specialist Auctioneer of Vintage and Classic Cars

guide price is estimated £650,000 to £800,000. As with any of these cars, provenance is everything!

Paul

edited to get the year right!

I though you might like to know that a 1929 Alfa Romeo 6c 1750cc supercharged sport will go under the hammer on March 27th

Richard Edmonds Auctions | Specialist Auctioneer of Vintage and Classic Cars

guide price is estimated £650,000 to £800,000. As with any of these cars, provenance is everything!

Paul

edited to get the year right!

Last edited:

P A D

Western Thunderer

Back on the P4, I've been chivvying away at the front end adding the air ducts. The white one (which cools the brakes on the real thing) is silicone and very flexible, so does not impede the movement of the steering. The black one is PVC but I've got some silicone tube on order to replace it.

On the other side there is an additional pipe at the top running from the small vent on the right side of the front clam to the cabin air vent. I've replaced the plastic panels with nickel silver, the diagonal one being straight to get rid of the dog legged moulded one. It should be at a sharper angle, but this is the best I can do without impeding the door hinges.

Here's a view from the front, showing the painted "holes" for the ducting.

The cockpit and floor panel have now been permanently glued and the gaps filled. More rubbing down required before painting but much better without the unsightly gap. The cooling ducts to the rear brakes have also been modified to be more prototypical.

The Jouef floor panel has also been replaced. Since removing the over scale and incorrect domed rivets from the upper body, which I'm not replacing, I've decided to ignore all the riveting, so the base will be left plain apart from the joint between the floor pan and the side panels which wrap under the fuel tanks.

I finally got rid of the last vestiges of the original paint clinging to the gaps in the grill on the rear clam. Nitromors, elbow grease and wire brush. I've also made a start on replacing the cast in lower rear lights.

The cockpit interior has now been replaced as I can brush paint it in-situ and add the dashboard and windscreen afterwards.

And I've made a start on replacing the hinges on the rear clam/cockpit.

Cheers,

Peter

On the other side there is an additional pipe at the top running from the small vent on the right side of the front clam to the cabin air vent. I've replaced the plastic panels with nickel silver, the diagonal one being straight to get rid of the dog legged moulded one. It should be at a sharper angle, but this is the best I can do without impeding the door hinges.

Here's a view from the front, showing the painted "holes" for the ducting.

The cockpit and floor panel have now been permanently glued and the gaps filled. More rubbing down required before painting but much better without the unsightly gap. The cooling ducts to the rear brakes have also been modified to be more prototypical.

The Jouef floor panel has also been replaced. Since removing the over scale and incorrect domed rivets from the upper body, which I'm not replacing, I've decided to ignore all the riveting, so the base will be left plain apart from the joint between the floor pan and the side panels which wrap under the fuel tanks.

I finally got rid of the last vestiges of the original paint clinging to the gaps in the grill on the rear clam. Nitromors, elbow grease and wire brush. I've also made a start on replacing the cast in lower rear lights.

The cockpit interior has now been replaced as I can brush paint it in-situ and add the dashboard and windscreen afterwards.

And I've made a start on replacing the hinges on the rear clam/cockpit.

Cheers,

Peter

P A D

Western Thunderer

Here's the fixing I made to lock down the rear clam. It is located through the hole in the clam and into another hole in the moulded air duct. It's a firm sliding fit so won't fall out.

And a representation of the rear clamps. They are purely cosmetic as the clam is held down by the side handles.

With the slightly warmer weather we've had of late I've been able to do some spraying. Halfords acid etch primer.

And top coated. It's a Ford colour which looked the nearest to Rosso Corsa that I could find in stock at Halfords. It's a bit on the orange side but the colour reproduction in the photo makes it look a lot oranger than it is.

The wheels have been brush painted in Revell gold enamel and the tyres lettered and lined in the same. Lettering was done with the airbrush through a stencil and the lining with a spring bow pen, rotated in a cross head screw placed in the axle hole. It should be on both sides, but I'm only doing the outside. The stencil is 1:20 scale but the only one I could find as I couldn't find any suitable transfers.

Heres the engine after painting. I've added a representation of the distributors and wiring. The V12 had 2 spark plugs per cylinder and 2 alternators per distributor, hence the number of cables. Cables are 0.4 copper wire blackened with a permanent black marker and touched up with Tamiya black acrylic after fixing. I don't know if it was the norm, but I've seen some photos where the cylinder covers were red and the transmission gold, so I've gone with that. The exhausts are not prototypical, but apart from painting them white and adding the missing loops between the two banks, I'm keeping them. The lower half of the transmission is fixed to the chassis. The engine is located in place then held by a screw through the transmission. With the spare wheel in place the screw is hidden.

This shows the plug leads before the air intake manifold was added.

Here's a view of the rear end with the spare wheel in place. I'm hoping to make some bungy cords to secure it once I can get hold of some sheering elastic. I've looked in my wife's sowing basket and she's got everything but! The locking clamps will be painted black and I'll run some dilute black into the grill and wipe the raised areas to hopefully make it look more realistic.

And some gratuitous images to finish off. The holes above the rear side wings are for adding the fixings (0.6M hex bolts). There will be some at the front as well under the side wings. I've managed to reduce the gap at the front of the rear clam with Isopon filler applied to the edge of the cockpit rear bulkhead, then scraped and sanded to shape. It seems robust enough and should be fine for a display model.

The front clam gap is quite small but there was nothing I could do about the doors.

Cheers,

Peter

And a representation of the rear clamps. They are purely cosmetic as the clam is held down by the side handles.

With the slightly warmer weather we've had of late I've been able to do some spraying. Halfords acid etch primer.

And top coated. It's a Ford colour which looked the nearest to Rosso Corsa that I could find in stock at Halfords. It's a bit on the orange side but the colour reproduction in the photo makes it look a lot oranger than it is.

The wheels have been brush painted in Revell gold enamel and the tyres lettered and lined in the same. Lettering was done with the airbrush through a stencil and the lining with a spring bow pen, rotated in a cross head screw placed in the axle hole. It should be on both sides, but I'm only doing the outside. The stencil is 1:20 scale but the only one I could find as I couldn't find any suitable transfers.

Heres the engine after painting. I've added a representation of the distributors and wiring. The V12 had 2 spark plugs per cylinder and 2 alternators per distributor, hence the number of cables. Cables are 0.4 copper wire blackened with a permanent black marker and touched up with Tamiya black acrylic after fixing. I don't know if it was the norm, but I've seen some photos where the cylinder covers were red and the transmission gold, so I've gone with that. The exhausts are not prototypical, but apart from painting them white and adding the missing loops between the two banks, I'm keeping them. The lower half of the transmission is fixed to the chassis. The engine is located in place then held by a screw through the transmission. With the spare wheel in place the screw is hidden.

This shows the plug leads before the air intake manifold was added.

Here's a view of the rear end with the spare wheel in place. I'm hoping to make some bungy cords to secure it once I can get hold of some sheering elastic. I've looked in my wife's sowing basket and she's got everything but! The locking clamps will be painted black and I'll run some dilute black into the grill and wipe the raised areas to hopefully make it look more realistic.

And some gratuitous images to finish off. The holes above the rear side wings are for adding the fixings (0.6M hex bolts). There will be some at the front as well under the side wings. I've managed to reduce the gap at the front of the rear clam with Isopon filler applied to the edge of the cockpit rear bulkhead, then scraped and sanded to shape. It seems robust enough and should be fine for a display model.

The front clam gap is quite small but there was nothing I could do about the doors.

Cheers,

Peter

P A D

Western Thunderer

I've made the bungy cords with shirring elastic and 0.4mm copper wire for the hooks. To make the hooks I coiled the wire around a drill shank held in the pin vice, then removed from the shank, trimmed the excess and formed the hook. On the prototype, four cords are used, but I've compromised and only made two but with double cords on each. I used a needle threader to feed the cord through the hooks and once I'd set the length between the hooks, a drop of super glue was used to fix them in place. After the CA had cured I cut off the excess elastic. Here's the first one completed.

And after securing the spare wheel. This was the fiddliest part of the whole operation.

I used a mix of Tamiya gloss red and matt yellow for the seats, but they have come out too glossy so I need to get some matt red and redo them.

I've also prepared the rear lights and knock off wheel nuts ready for fitting. The wheelnuts were open at the end so I filled them with isopon before painting. The plastic rod is just to hold them for painting. The main lights which were clear, have now been painted with Tamiya clear red and orange, and the smaller lights made from spare clear sprue painted with clear red.

Cheers,

Peter

And after securing the spare wheel. This was the fiddliest part of the whole operation.

I used a mix of Tamiya gloss red and matt yellow for the seats, but they have come out too glossy so I need to get some matt red and redo them.

I've also prepared the rear lights and knock off wheel nuts ready for fitting. The wheelnuts were open at the end so I filled them with isopon before painting. The plastic rod is just to hold them for painting. The main lights which were clear, have now been painted with Tamiya clear red and orange, and the smaller lights made from spare clear sprue painted with clear red.

Cheers,

Peter

P A D

Western Thunderer

So, the P4 is now completed. I could have done more, particularly to the engine and rear suspension, but I've achieved what I set out to do and considering the quality of the base model, I think it now looks a pretty reasonable representation of a Farrari 330 P4 Spyder. Here's a walk round of what it looks like now. The front clam does not sit down as tight on this side as it does on the right, but I didn't spot that until after the painting was done and I aint messing with it now.

The original Ferrari logo on the front clam was way too large and has been replaced with one of the correct size.

It took a lot of fettling to get the front light covers to fit as well ax they do, but they are still far from perfect.

That little domed vent above the oil filler cap was the only one I could drill out, so I've painted the front edge matt black to give an impression of an opening.

As I said, a lot more could have been done in this area but I'm still pleased with it and it's a big improvement on how it came. I'm particularly pleased with the bungy cords retaining the spare wheel.

The silicone tubing used for the brake cooling pipes should really be ribbed and I managed to achieve a reasonable representation by coiling copper wire around and glueing with cyano. However, the silicone tube doesn't take paint very well and it tends to flake off so I decided to just leave it bare and unribbed.

Here's the gubbins under the front clam.

And the cockpit. The steering wheel, rear view mirror, gear lever and gate were all scratched up from bits of brass sheet, rod and copper wire. Not visible in this shot but the dials have also been added to the instrument binnacle. They were black on the real thing but I had some white ones and decided to use these instead to make them more visible. The door hinges are piss poor but there was nothing I could do with them.

Looks better with the doors closed.

The seatbelts are 1:20 Tamiya items. Scale wise I think they look OK but they are from the 1970s as that's all Mr. Google could find for me on t'internet.

This view from the side gives a better view of the gear lever, gate and seat belts. The gear lever knob is the original after much spinning in the mini drill to turn it down. I think if the original was scaled up it would be twice the size of a tennis ball. Since the last post, I mixed up some red and yellow Tamiya paints to give a closer match to the car body colour and then re-painted the seats.

The cantilever windscreen wiper has been cobbled together from some bits from single arm etched wipers and brass wire.

Cheers,

Peter

The original Ferrari logo on the front clam was way too large and has been replaced with one of the correct size.

It took a lot of fettling to get the front light covers to fit as well ax they do, but they are still far from perfect.

That little domed vent above the oil filler cap was the only one I could drill out, so I've painted the front edge matt black to give an impression of an opening.

As I said, a lot more could have been done in this area but I'm still pleased with it and it's a big improvement on how it came. I'm particularly pleased with the bungy cords retaining the spare wheel.

The silicone tubing used for the brake cooling pipes should really be ribbed and I managed to achieve a reasonable representation by coiling copper wire around and glueing with cyano. However, the silicone tube doesn't take paint very well and it tends to flake off so I decided to just leave it bare and unribbed.

Here's the gubbins under the front clam.

And the cockpit. The steering wheel, rear view mirror, gear lever and gate were all scratched up from bits of brass sheet, rod and copper wire. Not visible in this shot but the dials have also been added to the instrument binnacle. They were black on the real thing but I had some white ones and decided to use these instead to make them more visible. The door hinges are piss poor but there was nothing I could do with them.

Looks better with the doors closed.

The seatbelts are 1:20 Tamiya items. Scale wise I think they look OK but they are from the 1970s as that's all Mr. Google could find for me on t'internet.

This view from the side gives a better view of the gear lever, gate and seat belts. The gear lever knob is the original after much spinning in the mini drill to turn it down. I think if the original was scaled up it would be twice the size of a tennis ball. Since the last post, I mixed up some red and yellow Tamiya paints to give a closer match to the car body colour and then re-painted the seats.

The cantilever windscreen wiper has been cobbled together from some bits from single arm etched wipers and brass wire.

Cheers,

Peter