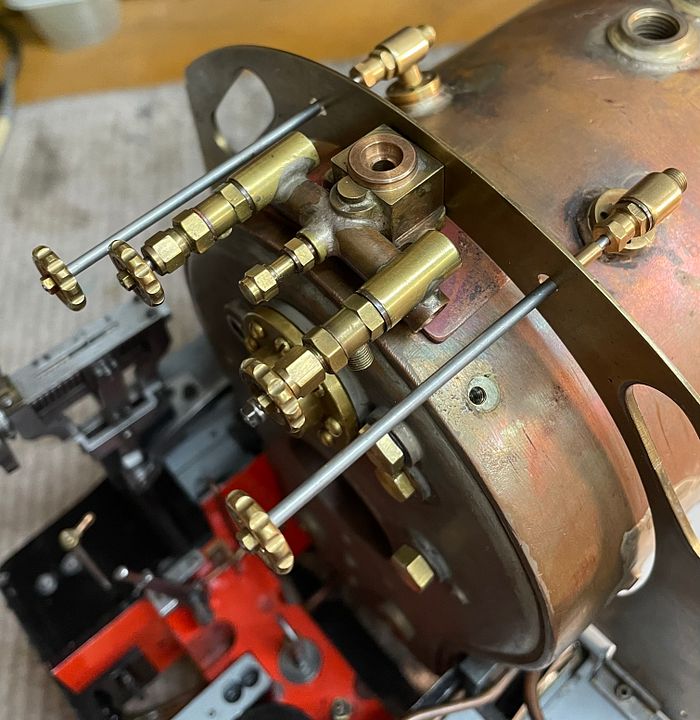

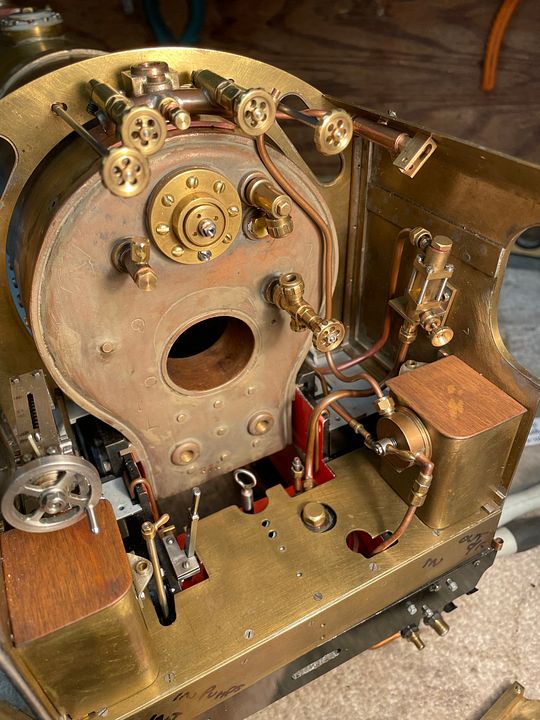

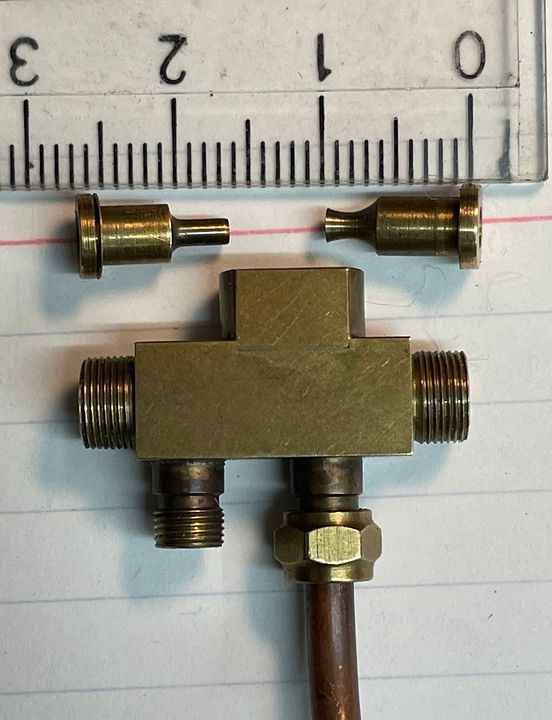

I have started to work on the rear end of Sir Sagramore (so to speak) and dismantled the RHS injector. This is more complete than the LHS, including the steam cone.

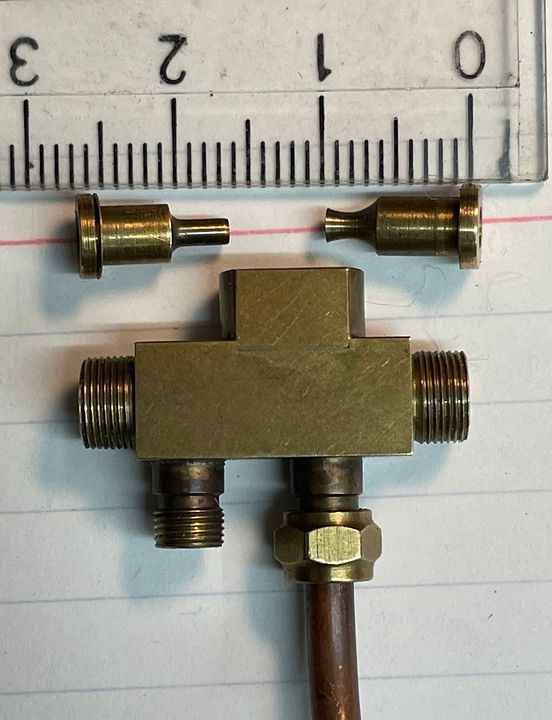

As for the LHS, there is a delivery cone, seen here with a view from the top.

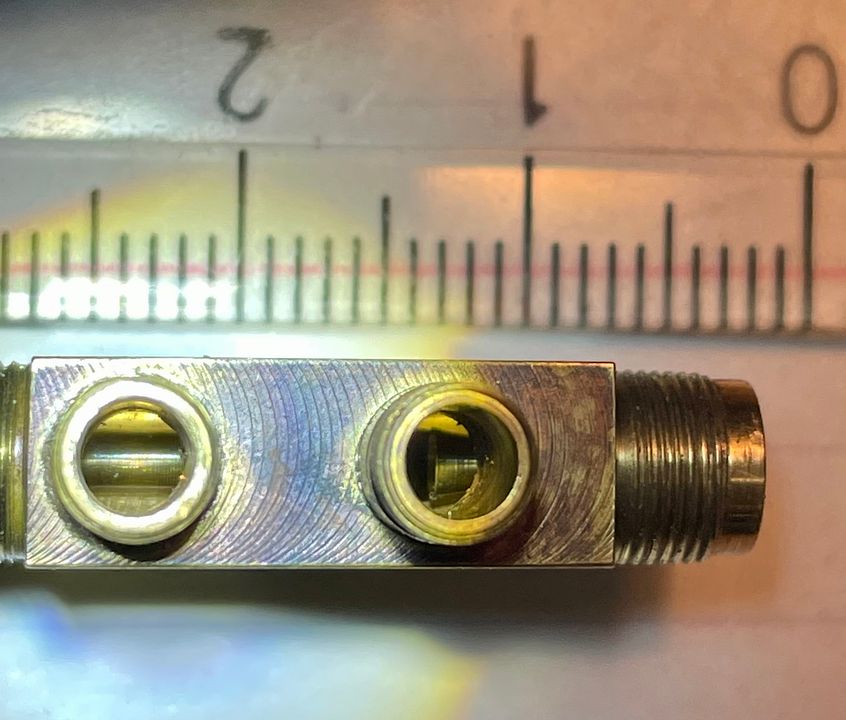

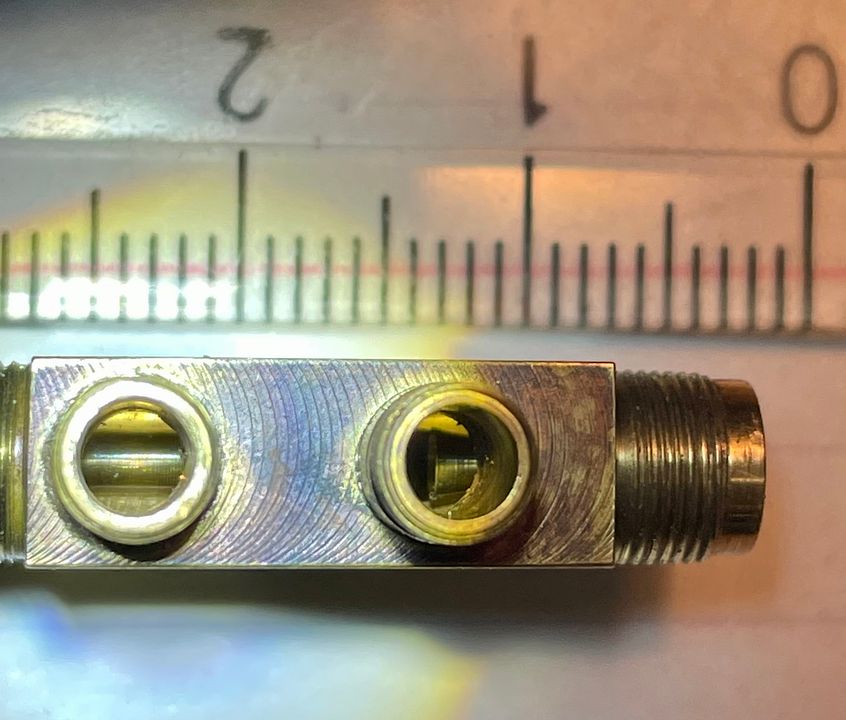

There is clearly the middle combining cone missing, whilst the relative positions of the other cones can be seen in this ventral view.

The steam cone finishes ahead of the water inlet opening (there is a fine spacing washer next to the mating surface with the injector body)whilst the bell opening of the delivery cone can be seen ahead of the overflow.

It would be good to get one of the Ian Jaycroft injectors working. It will need the combining cone reverse engineering and a ball and plug for the valve on top.

The questions that then arise are:

Any idea how to calculate what overall length / taper proportions the combining cone should have?

How would the combining cone be stabilised in the middle of the injector body?

What size ball for the valve - the hole is 3/32” diameter.

How much lift?

Maybe I’m expecting a bit much of this: I will definitely use a small Chiverton (commercial) injector on the other side, when I can source one.

Tim

As for the LHS, there is a delivery cone, seen here with a view from the top.

As for the LHS, there is a delivery cone, seen here with a view from the top.

Two starts or more?

Two starts or more?