Thanks Tony.

I often wonder if a lot of these poor performers were as bad as they are made out to be. Either way, from a modelling point of view the prototype performance is irrelevant and like the 2 6 4s, they are very handsome engines. With new member John Johnson starting a new thread on the 2 6 4, there's a bit of a Stanier tank fest going on at the moment.

So leaving the upper works for now, I made a start on the pony trucks. Here are the cast springs/axle boxes from MOK. Rather than wait for Sanspareil to produce further stock, I rang Dave Sharp and asked if he had any spare from his 8F which is not available at ths moment. Being the obliging chap he is, he kindly sold me 2 pairs. The hole in the casting is too large for Slaters axles so a bush needs to be added. Luckily I had some with a small enough outside diameter to allow them to fit after opening up the axlebox holes with a taper reamer. Here's a before and after shot.

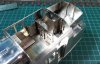

And all the bogie parts laid out for assembly. Note the half etch grooves on the underside of the arms on the A frame. These are for locating the the strips with the slope at one end. Looking at the GA, they should in fact fit centrally on the outer edge of the arms. I will drop Mike Edge a line in case he wants to modify the art work before producing his 4mm kit. I'm not sure how Mike built his trucks as the photos on his thread don't show it, but the holes in the side plate are just the right size for the axle after a touch with the reamer. This was useful in lining up the axle boxes for fitting to the outside faces.

First I assembled the echings using a glass plate and the axle to jig the parts and ensure all was square.

With the top hat bearings inserted into the axlebox, it was located onto the axle, held in the correct orientation with a pair of forceps over the spring and frame and the spring hanger brackets soldered to the frames. The top hat was then removed and the casting further soldered to fully fix it. This was repeated on the other side. Afterwards with the top hat removed, the frame holes were opened up with the reamer as the top hats provide all the bearing surface required. To just clear the wheels it was necessary to remove over 1mm from the outer face of the bearings in the lathe. Here the bearings are nos soldered in place.

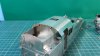

As can be seen, the side plates are fixed to the edge of the arms, not the under side.

And a view of the underside. I will add additional detail as per my 2 6 4 build but I'm not going the whole hog.

And with the wheels in. By chance, two 6BA nuts locked on the screw provide a nice fit with no slop and space the pivot the correct distance from the mounting spacer, so the the A frame and pony frame are level.

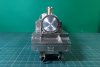

There's plenty of clearance for the pony to swing as well. The cheesehead and nuts can be seen from this angle, but will be hidden when the brake gear and slide bars are on.

A view from the front shows the spring hangers can be seen so it's worth adding them.

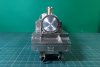

I couldn't resist a quick shot with the rear pony wheel placed under the frames. Boys will be boys.

John Johnson, if you read this, please note that all the closely spaced rivets were punched with the GW 4mm anvil with no bother. In my opinion, if you use the 2mm anvil the rivets will be too small.

I had a reply to a PM I sent to Roger Scanlon and he is kindly sending me the spare top feed and dome castings from his Chowbent kit, as he built it as a domeless variant. Many thanks Roger.

Cheers,

Peter

. I intend to replace the mudhole covers with Mr Mitchell's and I also need to change the rear fire iron bracket to match the rear one on the 3P. Thanks again to Tony for highlighting that.

. I intend to replace the mudhole covers with Mr Mitchell's and I also need to change the rear fire iron bracket to match the rear one on the 3P. Thanks again to Tony for highlighting that.