Nick Dunhill

Western Thunderer

The brief is to build a SR Z Class from a DMR Kit with the inside cylinder and some sensible upgrades. I have heard good things about the kit so I am going to enjoy the build.

The box had a set of Laurie Griffin cast coupling and connecting rods within. I'm not a fan, normally, of pre-made rods (Premier, LGM etc.,) preferring to laminate etches, they just need some patient filing and polishing. Also I like to be in control of the rod and axle centres. I looked at the etchings for the coupling rods and thought that they were a bit two-dimensional, so I decided in retrospect to use the cast ones. They needed a bit of fettling but came up nicely.

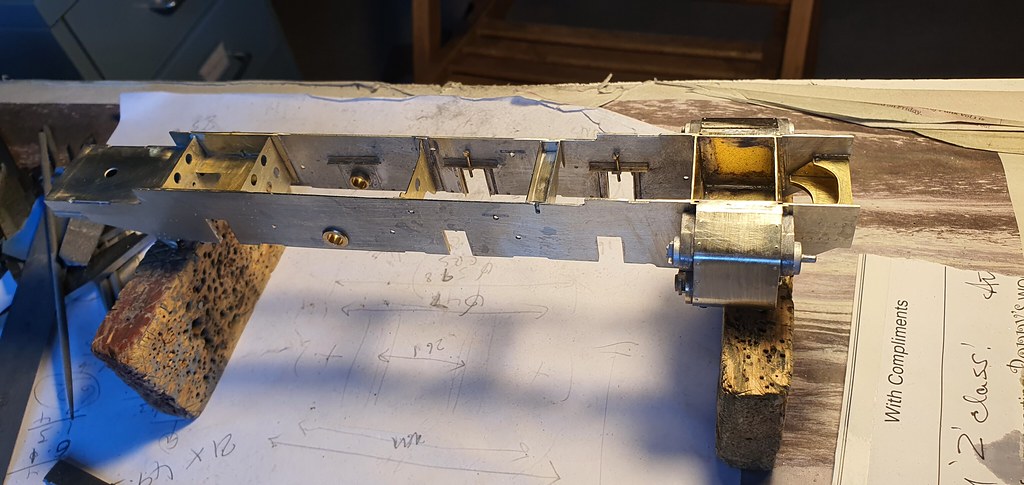

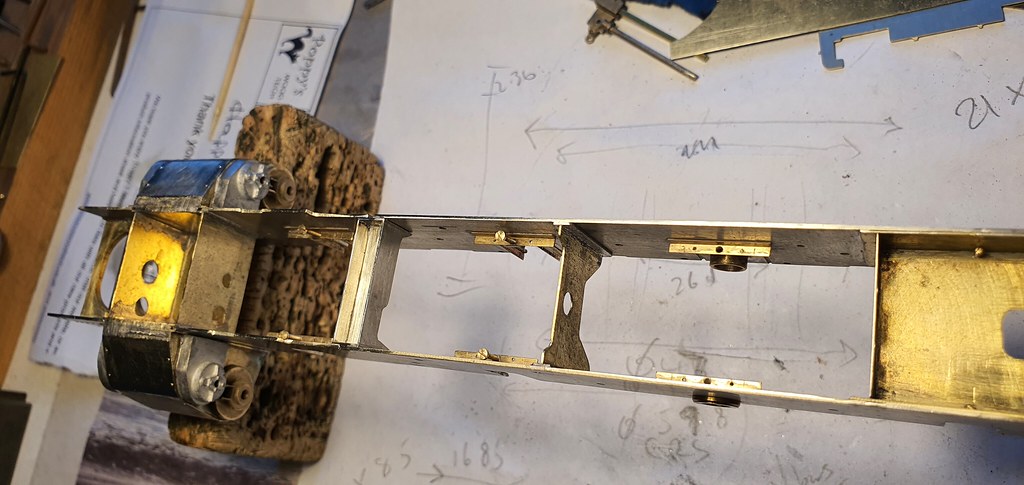

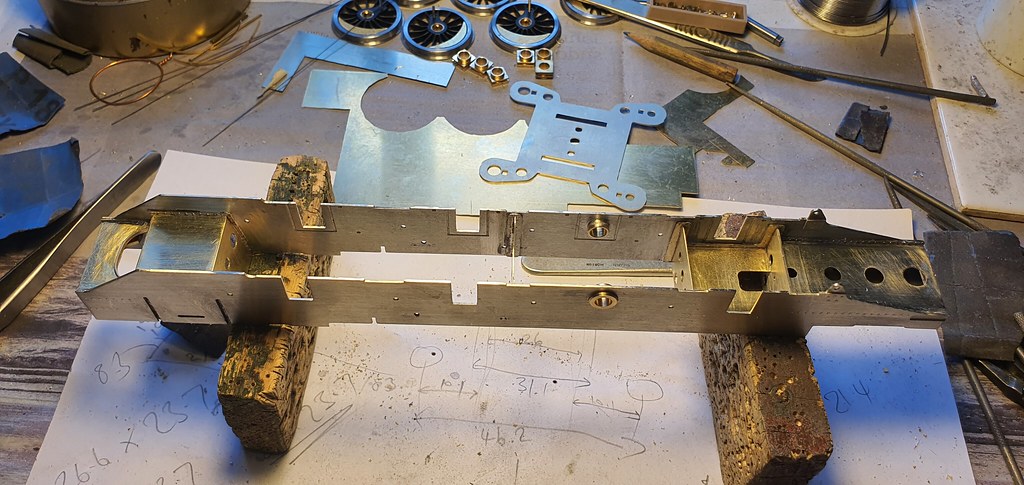

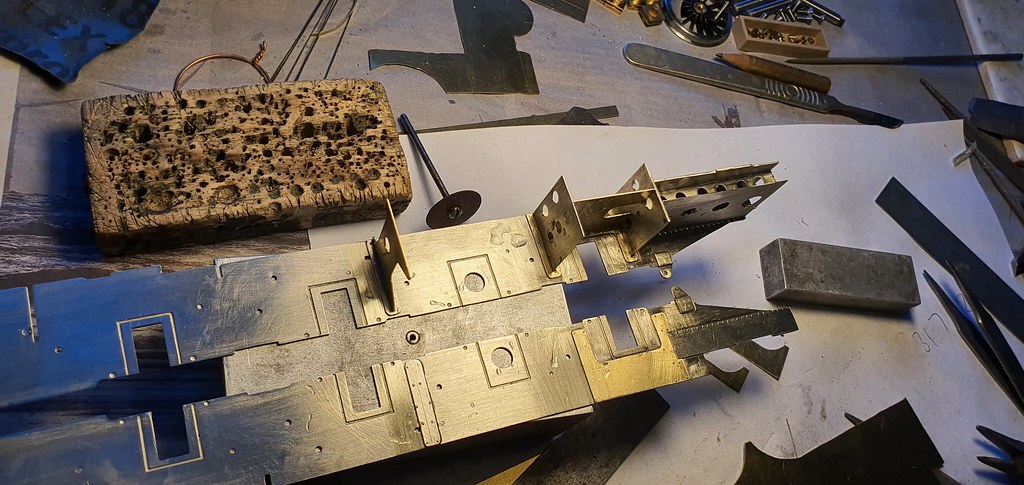

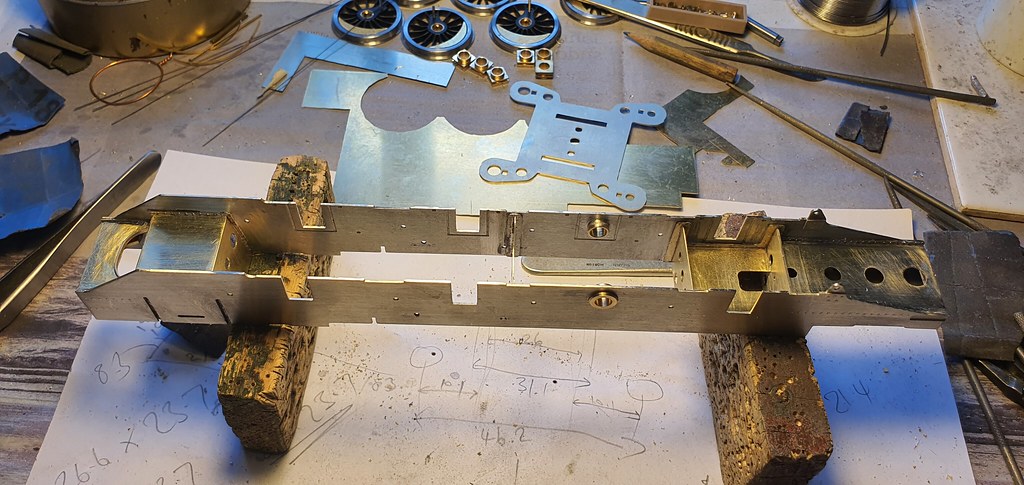

The frames are a pretty good representation of the real loco, well below the chassis at least. The bits of the chassis on view above the footplate are designed to be planted on the footplate, I'll deal with those bits later. The frame stays provided are very functional, but if you're building the inside motion and cylinder they're all in the wrong place except the rearmost. Luckily I have a GA so I just made what was on the real thing.

Anthony Garton of Poppy's Woodtech fame sent me one of his Loco Builder's Boxes to try out as a chassis building jig. Below is a short video of how I put the axle boxes in the chassis using the box. I suppose I should note this in the Register of Member's Interests (unlike Hancock and the rest,) although I only got a free box for making the video, no royalties. The box does make the process much easier though.

Thanks to Tito Puente

One thing that won't make the job easier was the ridiculous way the boiler etch had been pre-rolled. It would have certainly been better left flat.

I'll have to scratchbuild a boiler now. Thankfully the etch for the smokebox was salvegable.

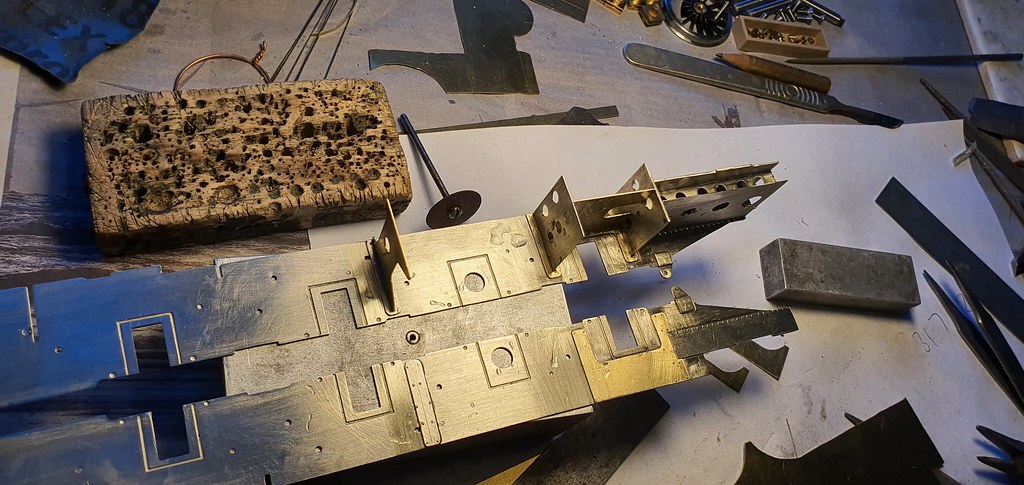

I also made a start scratchbuilding the outside cylinders. As I'd already gone a bit far off the script the etches provided for the cylinders didn't fit. They weren't quite right anyway.

More pics here: nick dunhill

The box had a set of Laurie Griffin cast coupling and connecting rods within. I'm not a fan, normally, of pre-made rods (Premier, LGM etc.,) preferring to laminate etches, they just need some patient filing and polishing. Also I like to be in control of the rod and axle centres. I looked at the etchings for the coupling rods and thought that they were a bit two-dimensional, so I decided in retrospect to use the cast ones. They needed a bit of fettling but came up nicely.

The frames are a pretty good representation of the real loco, well below the chassis at least. The bits of the chassis on view above the footplate are designed to be planted on the footplate, I'll deal with those bits later. The frame stays provided are very functional, but if you're building the inside motion and cylinder they're all in the wrong place except the rearmost. Luckily I have a GA so I just made what was on the real thing.

Anthony Garton of Poppy's Woodtech fame sent me one of his Loco Builder's Boxes to try out as a chassis building jig. Below is a short video of how I put the axle boxes in the chassis using the box. I suppose I should note this in the Register of Member's Interests (unlike Hancock and the rest,) although I only got a free box for making the video, no royalties. The box does make the process much easier though.

One thing that won't make the job easier was the ridiculous way the boiler etch had been pre-rolled. It would have certainly been better left flat.

I'll have to scratchbuild a boiler now. Thankfully the etch for the smokebox was salvegable.

I also made a start scratchbuilding the outside cylinders. As I'd already gone a bit far off the script the etches provided for the cylinders didn't fit. They weren't quite right anyway.

More pics here: nick dunhill